Five-stage equal-length three-dimensional triangular opening rolled iron core

A triangular, rolled iron core technology, applied in the direction of transformer/inductor cores, etc., can solve the problems of partial utilization, increased material costs, material waste, etc., to save equipment investment costs, reduce processing costs, and reduce shelving rates Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

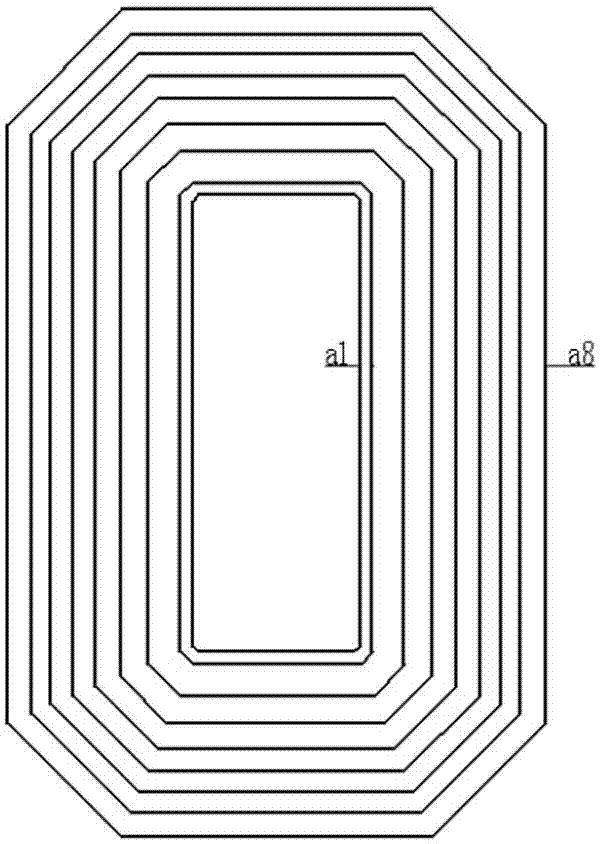

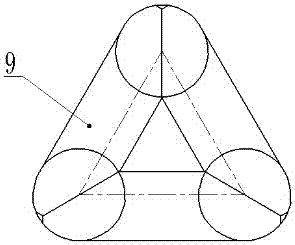

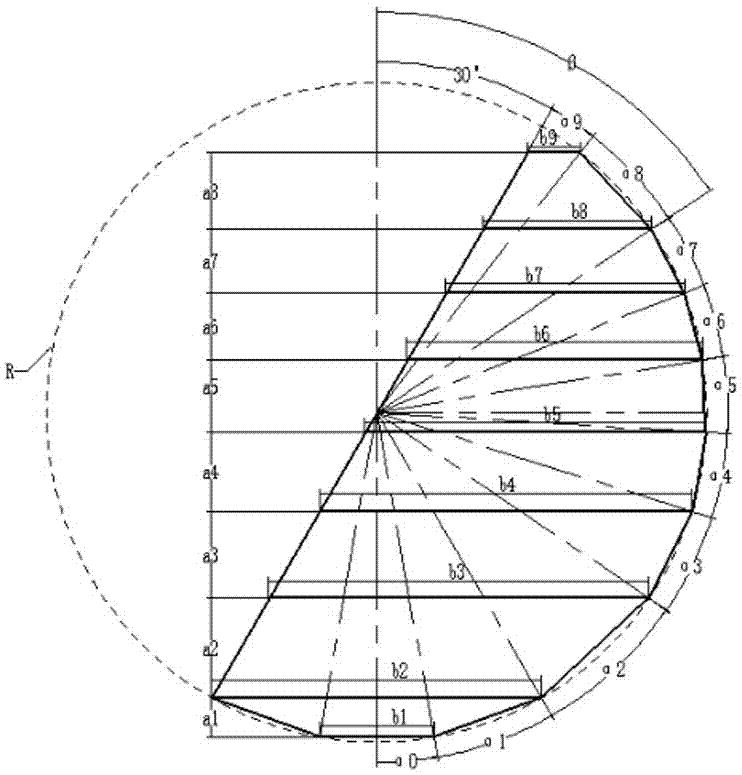

[0019] like figure 1 , figure 2 and image 3 As shown, the five-level equal-length three-dimensional triangular open wound iron core includes three identical single frames 9, and each single frame 9 is provided with a grounding piece. In order to enable the material strip to achieve a stable and shaped structure after being bent, the single frame 9 is provided with a 45° chamfer at the bending position. Each single frame 9 is provided with an opening on the core column or the upper iron yoke, and the material strips forming the single frame are processed into a U-shape or a closed rectangle on a special coiled iron core shearing and folding equipment. The single frame 9 is assembled on the silicon steel sheet chip table, and is bound and fixed with a binding tape after the assembly is completed. The assembled three single frames are then assembled in a special fixture, and the core columns of the two adjacent single frames are fixed with binding tapes. During the assembly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| stacking factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com