Laboratory simulation method for borehole gas drainage and test method for sealing performance of hole sealing materials

A technology for laboratory simulation and gas drainage, which is applied in the fields of gas discharge, earthwork drilling, measurement, etc., can solve the problems of high manpower and material resources and unsatisfactory test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

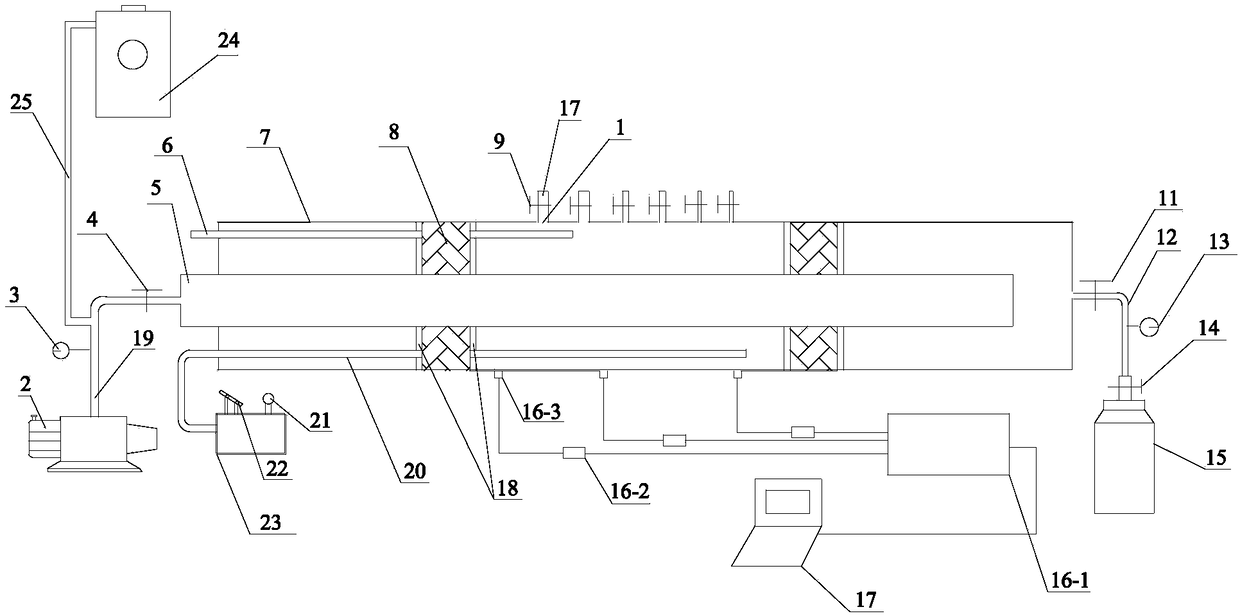

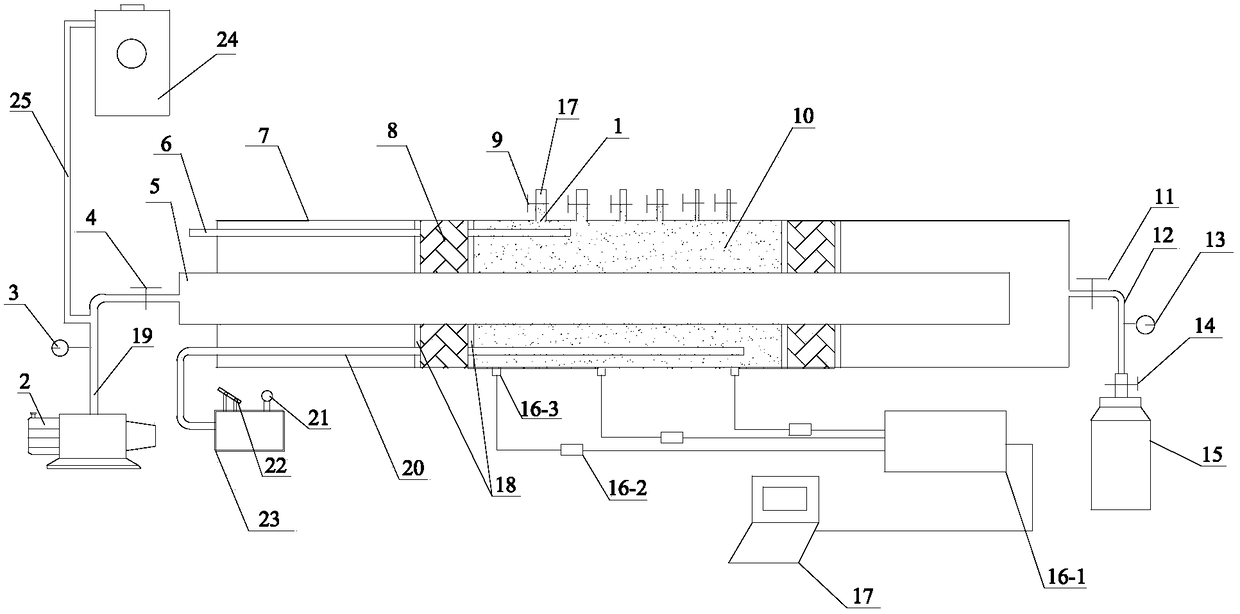

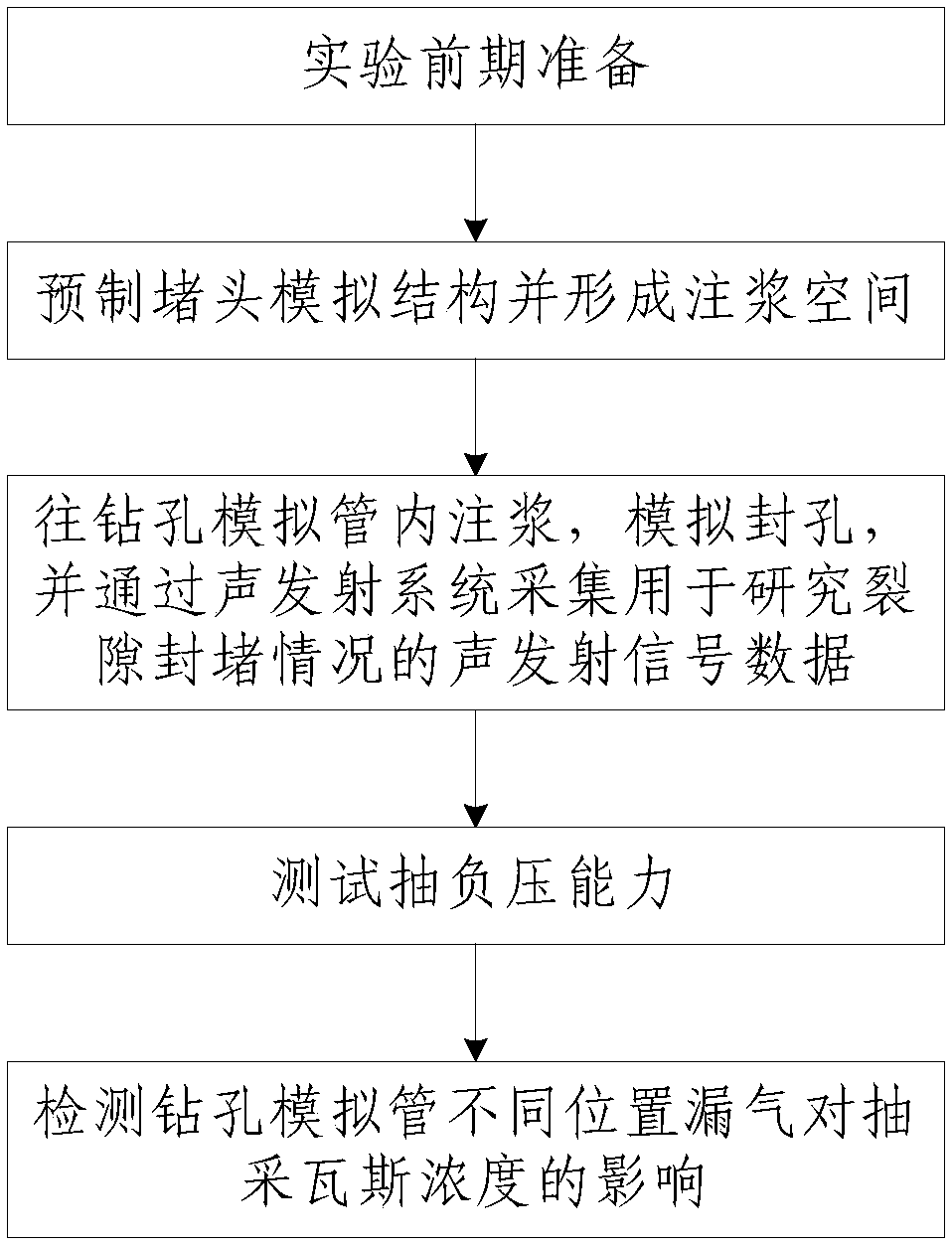

[0088] Such as figure 1As shown, the borehole gas drainage laboratory simulation system of the present invention includes a borehole simulation pipe 7, a hole sealing grouting system, a gas pressure simulation loading system and a gas detector 24, and an acoustic emission system and an acoustic emission system. A connected computer 17; the two ends of the drilling simulation pipe 7 are provided with a plug simulation structure 8, and a section of the drilling simulation pipe 7 between the two plug simulation structures 8 is provided with a plurality of crack simulation holes on the pipe wall 1. A crack simulation tube 17 is connected to the crack simulation hole 1, and an air leakage detection switch 9 is connected to the crack simulation tube 17;

[0089] The sealing grouting system includes a grouting pipe 20 and a grouting pipe 6 extending into the drilling simulation pipe 7, and a grouting pump 23 connected with the grouting pipe 20; Grouting handle 22 and grouting pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com