Drilling leakage zone position recognition system

A technology for identifying system and leakage, applied in earth-moving drilling, wellbore/well components, measurement, etc., can solve the problems of cumbersome, complicated construction, increase well control risk, etc., to reduce the link of reading data and reduce tripping Drilling time, effect of reducing well control risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

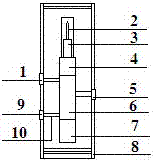

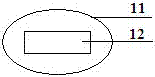

[0016] to combine figure 1 , figure 2 The implementation process of the present invention will be described. The leakage measurement nipple consists of a magnetic field antenna 2, a radio frequency signal reader 3, a data storage cabin 4, an instrument circuit cabin 6, a battery cabin 7, an insulating support rod 10, a flow sensor 5, a temperature sensor 9, a pressure sensor 1 and an outer tube short Section 8 is composed. The magnetic field antenna 2 is connected with the radio frequency signal reader 3 through a data transmission line. Outer cylinder nipple 8 is made of drill collar, grooves are carved on the outer wall, flow sensor 5, temperature sensor 9, pressure sensor 1 are installed, holes are drilled through the circuit, and sealed with sealing plugs. Insulating support rods 10 are respectively installed at the openings of the inner wall of the short joint 8 of the outer cylinder, and circuits are installed inside the insulating support rods 10. One end of the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com