Mining method for polyhalite

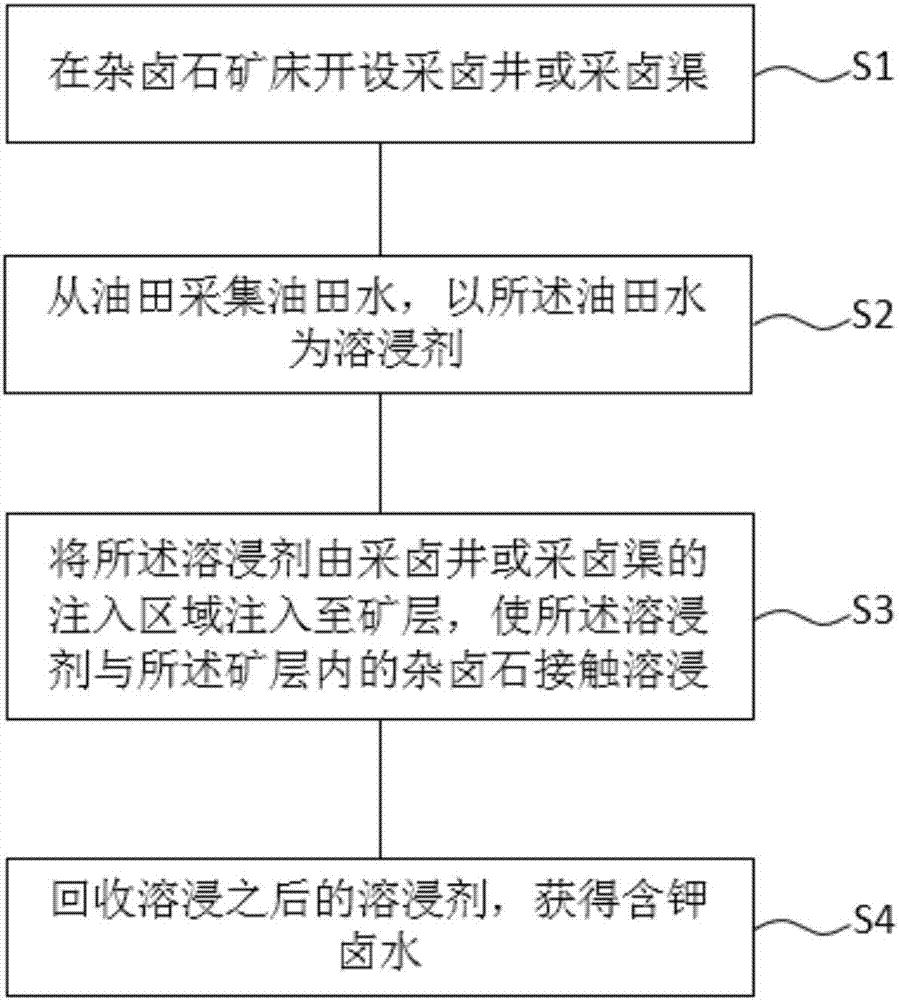

A mining method, the technology of polyhalite, applied in the field of salt chemical industry, can solve the problems of ineffective mining of polyhalite, high cost, pollution, etc., and achieve the effect of solving the problem of oil field drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

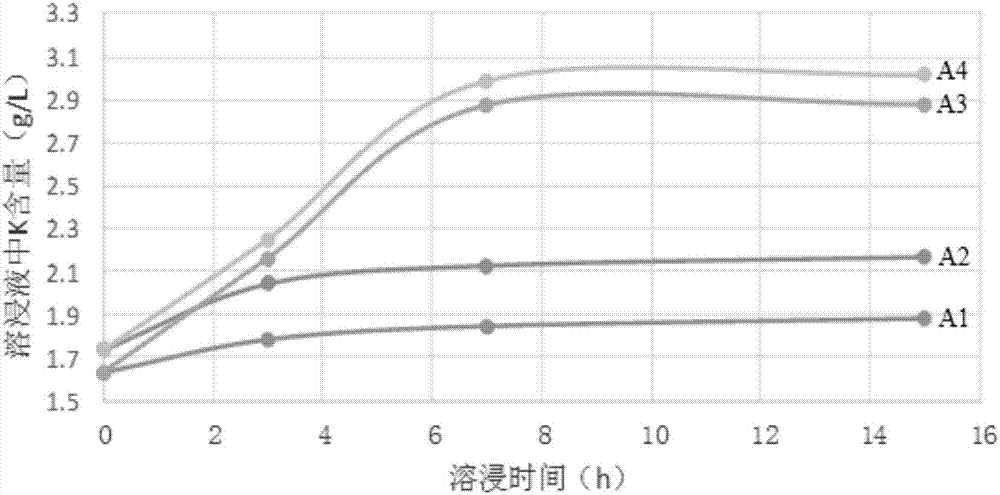

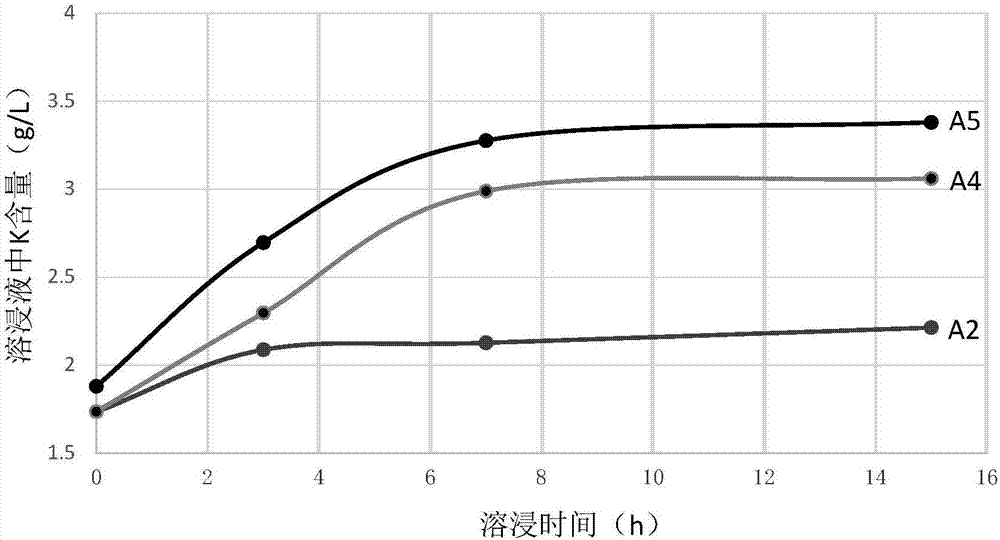

experiment example A1 and A3

[0040] A1. Using distilled water as the leaching agent, leaching 2g of polyhalite with 50ml of distilled water at a temperature of 25°C.

[0041] A2. Using oilfield water as a leaching agent, leaching 2g of polyhalite with 50ml of oilfield water at a temperature of 25°C.

[0042] A3. Using distilled water as the leaching agent, leaching 2g of polyhalite with 50ml of distilled water at a temperature of 50°C.

[0043] A4. Using oilfield water as the leaching agent, leaching 2g of polyhalite with 50ml of oilfield water at a temperature of 50°C.

[0044] Each group of experiments was sampled 4 times. For the first time, after pouring the leaching agent into the polyhalite powder, gently stir it with a glass rod for 3 seconds, let it stand for 20 minutes, and sample 1ml. Then, the experiment was carried out in the electrothermal constant temperature magnetic stirring water bath, the magnetic stirring speed was set to 200 rpm, and the second, third and fourth sampling were carried ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com