House frame

A frame and house technology, applied in construction, building construction, etc., can solve the problems of limited load-bearing capacity and limited load-bearing capacity of house frames, and achieve the effect of saving assembly time and improving construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0048] The house frame includes a single-layer frame, and the house frame includes a one-layer or at least two-layer single-layer frame. The single-layer frame includes columns and beams, and the beams and columns are connected to form the entire single-layer frame.

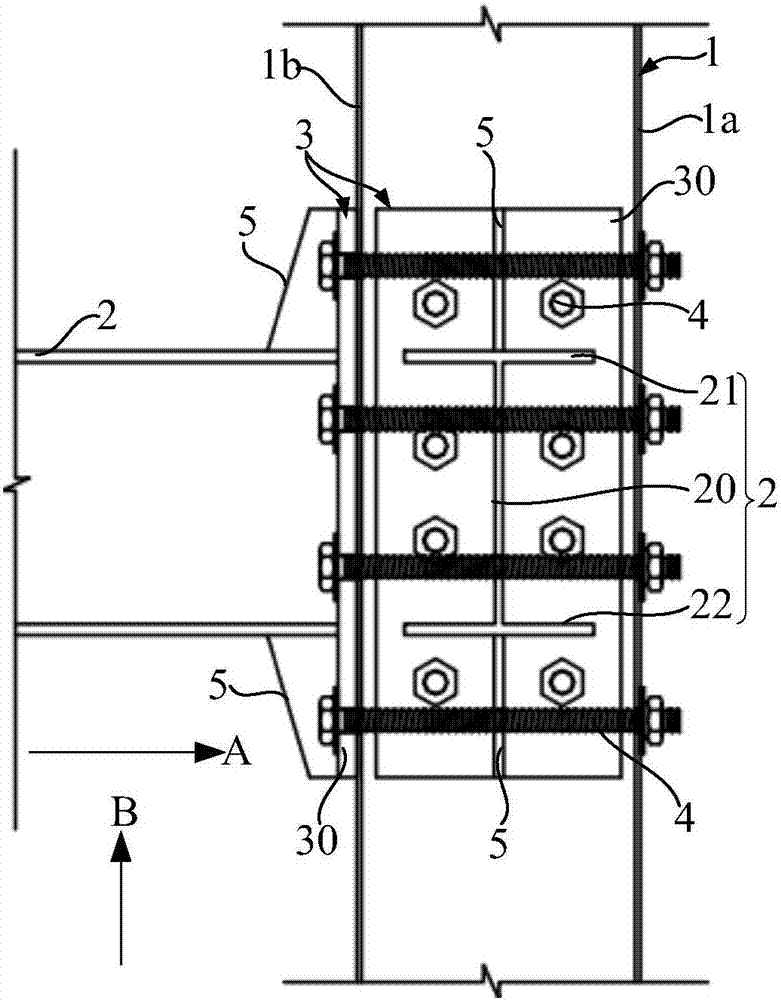

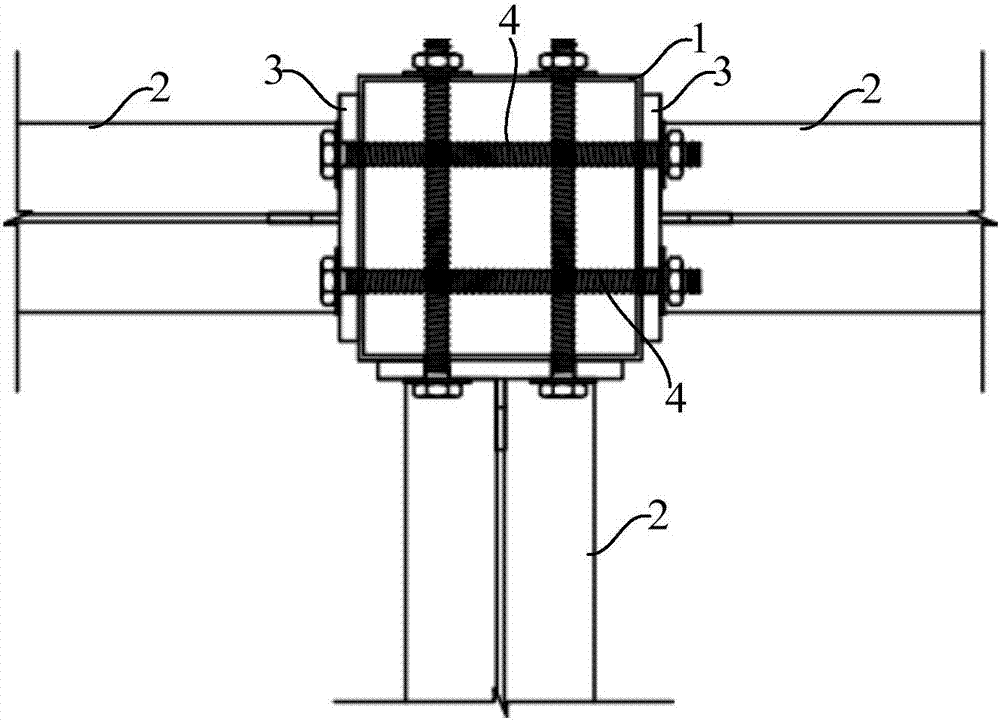

[0049] refer to figure 1 , the column 1 and the beam 2 are connected through the first connecting piece 3 , and the first connecting piece 3 and the column 1 are connected with the bolt 4 .

[0050] The first connecting piece 3 and the column 1 are connected by bolts 4 , and there is no welding area between the column 1 and the first connecting piece 3 . When the crossbeam 2 is subjected to relatively large pressure in the vertical direction, the bolts 4 connecting the first connecting piece 3 and the column 1 can bear relatively large pressure without breaking easily, which can improve the load-bearing capacity of the building frame.

[0051] Bolt 4 can be selected from high-strength bolts, which have higher s...

no. 2 example

[0062] Compared with the first embodiment, the difference of the second embodiment is:

[0063] refer to Figure 5 and combine Image 6 The first connector 13 includes a plate portion 130 and an extension portion 131 extending from the plate portion 130 toward the beam 12. The plate portion 130 and the column 11 are connected by bolts (hereinafter referred to as first bolts 14), and the extension portion 131 is connected to the beam 12. 12 are also connected by bolts (hereinafter referred to as second bolts 16).

[0064] The first bolt 14 only passes through the side wall 11 a of the column 11 and the plate portion 130 and the plate portion 130 , and the first bolt 14 does not pass through the side wall 11 b of the column 11 opposite to the side wall 11 a. refer to Image 6 and combine Figure 7 , the side wall 11a of the column 11 and the plate portion 130 are provided with through holes and aligned. Taking the through hole 130a provided on the plate portion 130 as an ex...

no. 3 example

[0082] Compared with the second embodiment, the third embodiment differs in that:

[0083] refer to Figure 11 , the beam 22 is a square beam, and the corresponding ends of the square beam along the length direction are accommodated in the groove 230 of the first connecting member 23 . An operation window 220 is provided in the top wall of the crossbeam 22 , through the operation window 220 , a second bolt 26 is installed to connect the sidewall of the crossbeam 22 and the groove wall of the groove 230 . After the frame of the house is assembled, concrete can be filled in the square beams at the construction site to enhance the strength of the house.

[0084] As an improvement, the operating window can be arranged in the bottom wall of the beam. Thus, operating windows may be provided in the top and / or bottom wall of the beam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com