Improved TUP thin film

A kind of thin film, benign technology, applied in the field of improved TUP film, can solve the problems of lower tensile strength, poor stability, poor water resistance and poor shrinkage of TPU film products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

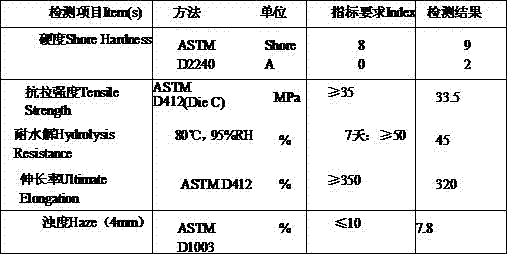

[0009] Example 1: 15 parts of diphenylmethane diisocyanate; 40 parts of adhesive; 3 parts of glycol; 1 part of polybutylene terephthalate; 1 part of ion exchange resin; 1 part of crosslinking agent; 1 part of stabilizer share.

[0010] Its test structure is as follows:

[0011]

Embodiment 2

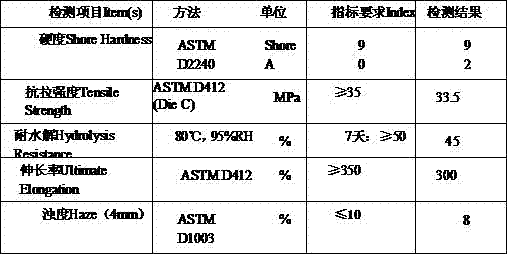

[0012] Example 2: 25 parts of diphenylmethane diisocyanate; 55 parts of adhesive; 5 parts of diol; 3 parts of polybutylene terephthalate; 3 parts of ion exchange resin; 2 parts of crosslinking agent; 1 part of stabilizer .

[0013] The test results are as follows:

[0014]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com