Aconite straw recycling method and soil or water restoration method

A repair method, the technology of aconite, applied in the field of materials, can solve environmental pollution and other problems, achieve the effect of low price, low corrosion, and beneficial to ecological environment protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

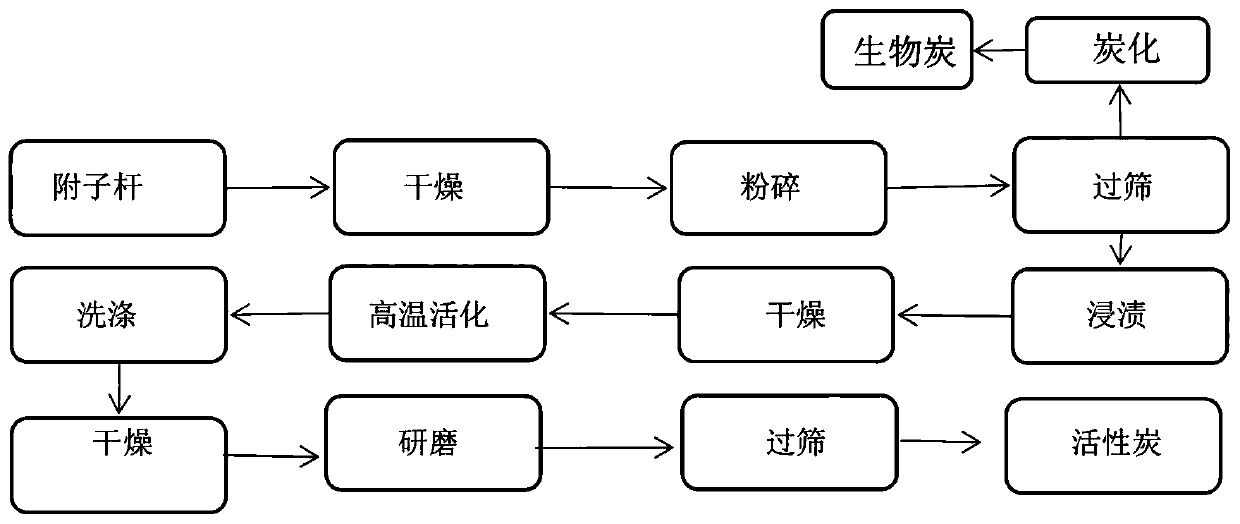

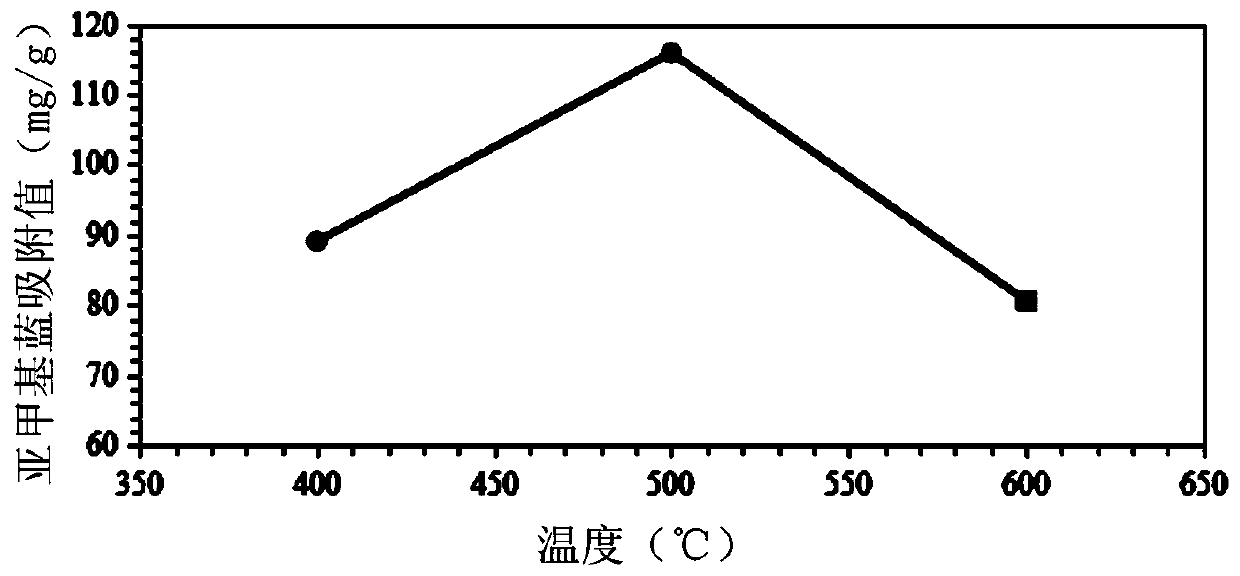

[0042] The air-dried aconite stalks are peeled, crushed, dried to constant weight, passed through a 35-mesh standard sieve, and set aside. Weigh 10.00g of processed aconite stalk powder, put it into a 250mL beaker, then add the prepared 40wt% phosphoric acid solution into the beaker according to the mass ratio of phosphoric acid and aconite stalks at 2.5:1, stir evenly, and then cover with a parafilm Seal and soak at room temperature for 12 hours. Then put it into a constant temperature drying oven for drying, the drying temperature is set at 80° C., and the drying time is 5 hours. The dried sample was taken out, put into a porcelain boat (a layer of newspaper was laid under the porcelain boat), uncovered, and then put into a high-temperature tube furnace, and the temperature was raised at a rate of 10°C / min under the protection of nitrogen. The temperature is raised to the required activation temperature of 400°C, 500°C, 600°C, and the activation temperature is maintained fo...

example 2

[0050] The air-dried aconite stalks are peeled, crushed, dried to constant weight, passed through a 35-mesh standard sieve, and set aside. Weigh 10.00g of processed aconite stalk powder, mix the aconite stalk powder with KOH directly according to the mass ratio of KOH and aconite stalk powder as 4:1, or, according to KOH 2 CO 3 The mass ratio of Aconite stalk powder and Aconite stalk powder is 1:1. 2 CO 3 Mix directly, put the mixed sample into a porcelain boat (a layer of newspaper is placed under the porcelain boat), uncover it, then put it into a high-temperature tube furnace, and raise the temperature at a rate of 10°C / min under the protection of nitrogen, from The room temperature was raised to the required activation temperature of 800°C, and the activation temperature was maintained for 2.5h. After the temperature in the tube furnace dropped, the activated sample was taken out from the tube furnace and cooled to room temperature. Then, wash the sample with distilled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com