Fluorinated copolymer, and surface modifier containing same as active ingredient

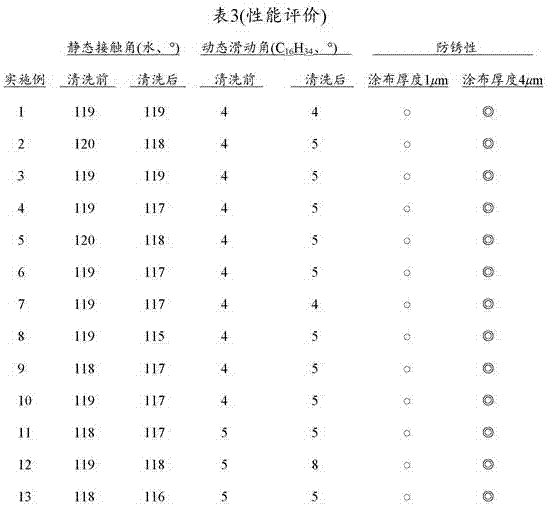

一种表面改性剂、共聚物的技术,应用在其他化学过程、化学仪器和方法、涂层等方向,能够解决剥离力小、金属防锈性未完全满足、动态滑动角不满足要求等问题,达到防油性优异、动态滑动角优异、防锈性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

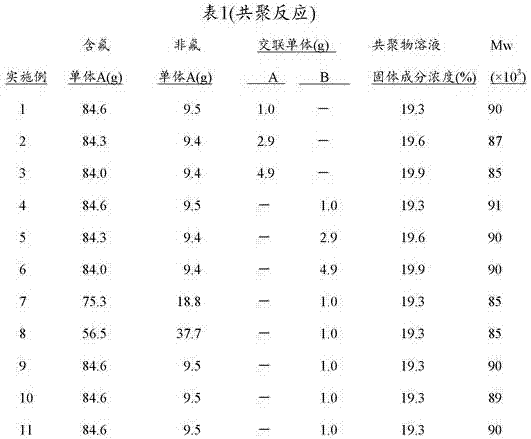

Embodiment 1

[0047] C 4 f 9 (CH 2 CF 2 )(CF 2 CF 2 ) 2 (CH 2 CH 2 )OCOCH=CH 2 [Fluorinated monomer A] 84.6g

[0048] Benzyl methacrylate (Mitsubishi Rayon product Acryl Ester BZ) 9.5 g

[0049] [Non-fluorine monomer A]

[0050] 3-Acryloxypropyltrimethoxysilane (Tokyo Chemical Industry A1597) 1.0g

[0051] [Crosslinking Monomer A]

[0052] Bis(4-tert-butylcyclohexyl)peroxydicarbonate mixture 1.3g

[0053] (Chemical Akzo product Perkadox 16)

[0054] 1,3-Bis(trifluoromethyl)benzene (Central Glass MTF) 403.6g

[0055] [Solvent A]

[0056] Each of the above-mentioned components except the polymerization initiator was put into a reactor having a capacity of 500 ml including a condenser, and replaced with nitrogen for 30 minutes. Further, a polymerization initiator (500 g in total) was added stepwise to the reactor, the temperature in the reactor was gradually raised by 50° C., and a polymerization reaction was performed at this temperature for 23 hours while stirring.

[0057] ...

Embodiment 2~3

[0077] In Example 1, the amount of each monomer was changed as described in Table 1 and used. The polymerization initiator doses were all 1.3 g.

Embodiment 4~8

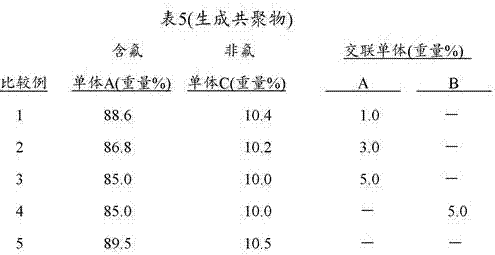

[0079] In Example 1, 3-methacryloxypropyltrimethoxysilane (crosslinking monomer B, Tokyo Chemical Industry M0725) was used instead of crosslinking monomer A, as described in Table 1, and each monomer was changed. Use after measuring. The polymerization initiator doses were all 1.3 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com