Damping structure for reducing vibration of transformer oil tank

A transformer oil tank and damping structure technology, which is applied in the field of damping structures, can solve problems such as unfavorable transportation and installation of transformers, increasing costs, occupying space, and affecting safe operation of transformers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

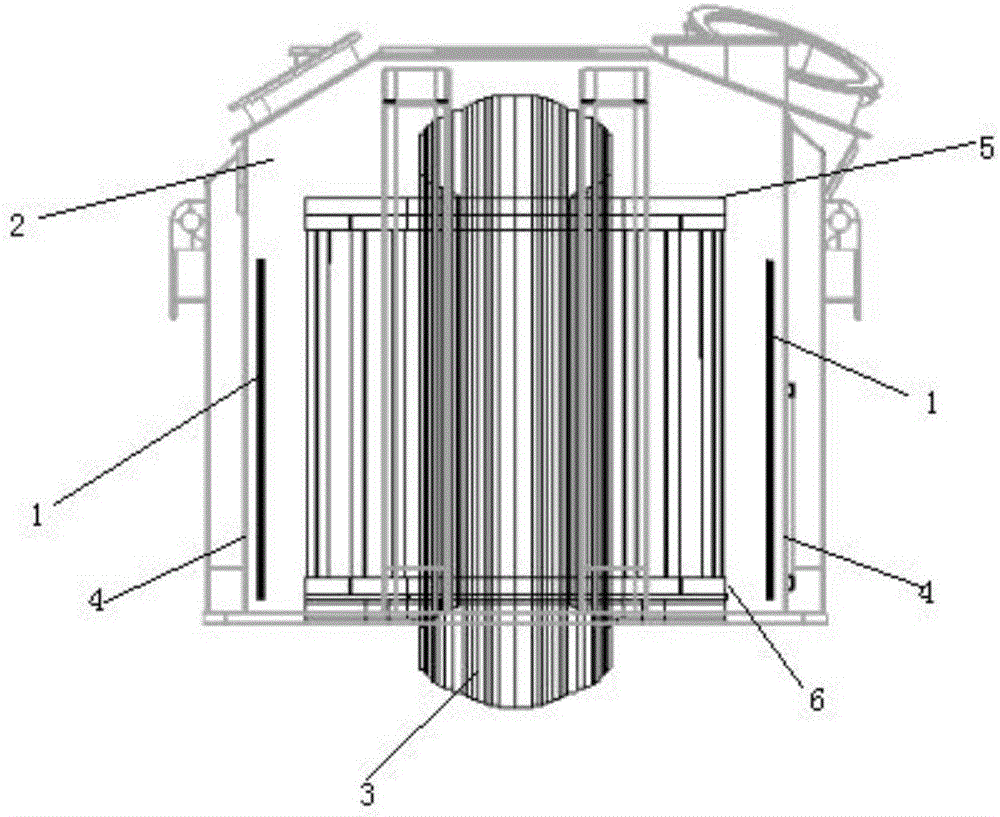

[0016] A damping structure used to reduce the vibration of the transformer oil tank, such as figure 1 As shown, it includes two metal perforated plates 1 arranged inside the upper fuel tank 2 of the transformer and located on the front and rear sides of the iron core 3 respectively. The two metal perforated plates 1 are all parallel to the two wide surfaces and leave space There is a gap; the upper and lower edges of the metal perforated plate 1 are respectively flush with the upper end ring 5 and the lower end ring 6 of the transformer, and the metal perforated plate 1 covers the iron core 3 in the length direction.

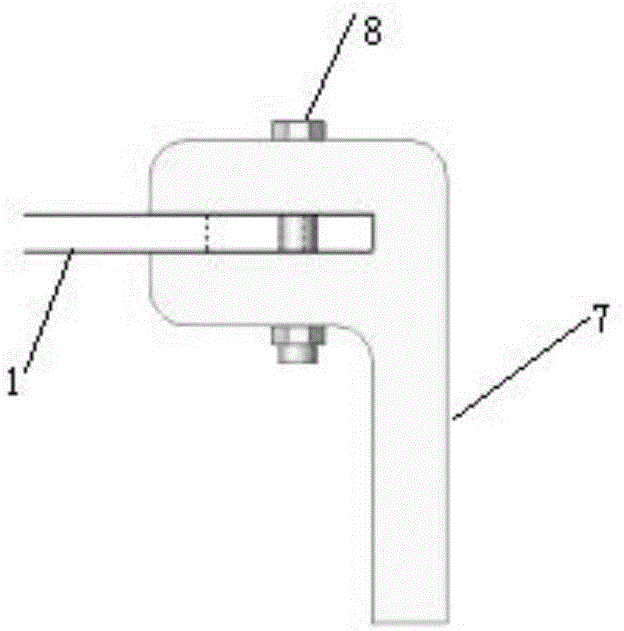

[0017] Such as figure 2 As shown, the metal perforated plate 1 is fixed on the inner wall 4 of the fuel tank through the F-shaped rib 7 and the bolt 8, the end of the vertical plate of the F-shaped rib 7 is vertically installed on the inner wall 4 of the fuel tank, and the edge of the metal perforated plate 1 is inserted into the F-shaped rib 7 between the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com