Method for directly generating vortex beam with adjustable order in cavity

A technology of vortex beam and order, applied in the field of laser, can solve the problem of weak ability of order adjustment of vortex beam, and achieve the effect of stable transmission, high purity, and improved ability of order adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings.

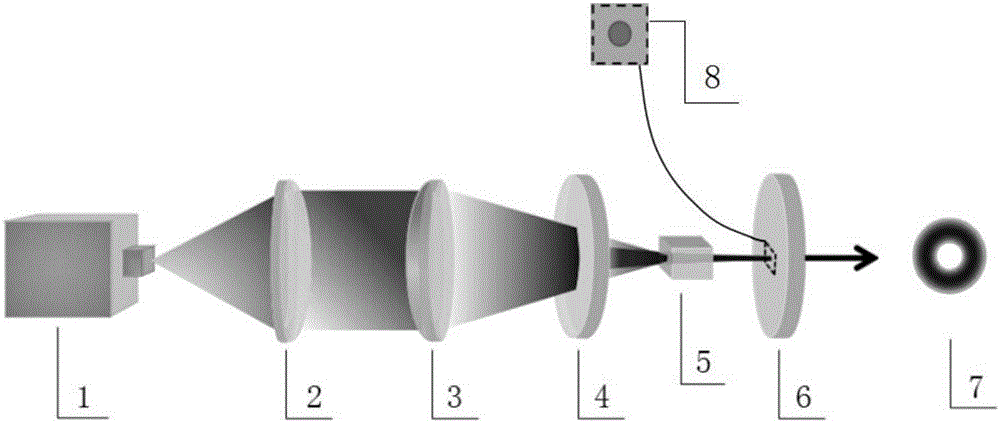

[0023] The method for directly generating an order-adjustable vortex beam in a cavity of the present invention comprises the following steps:

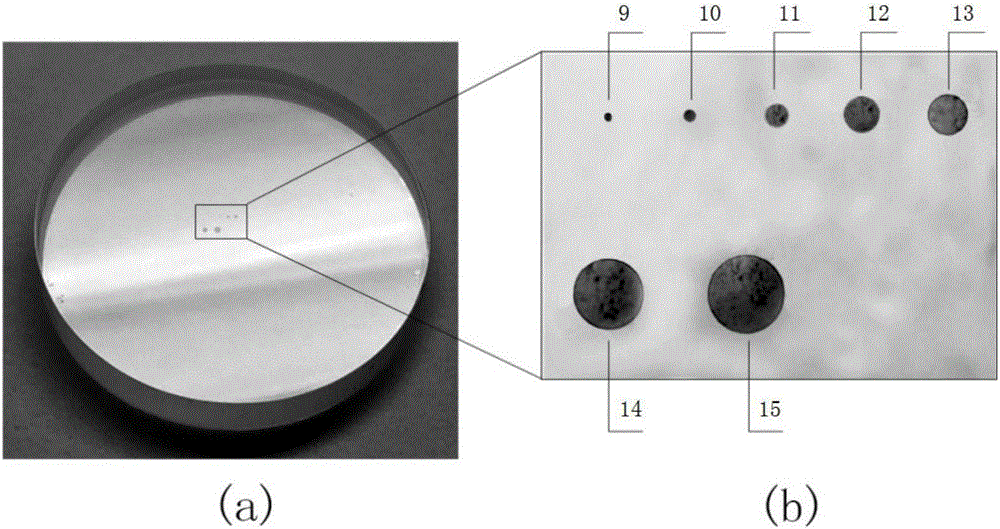

[0024] 1) Build a laser, the laser output end of the laser is engraved with a series of circular micro-holes with different diameters, adjust the laser to output laser;

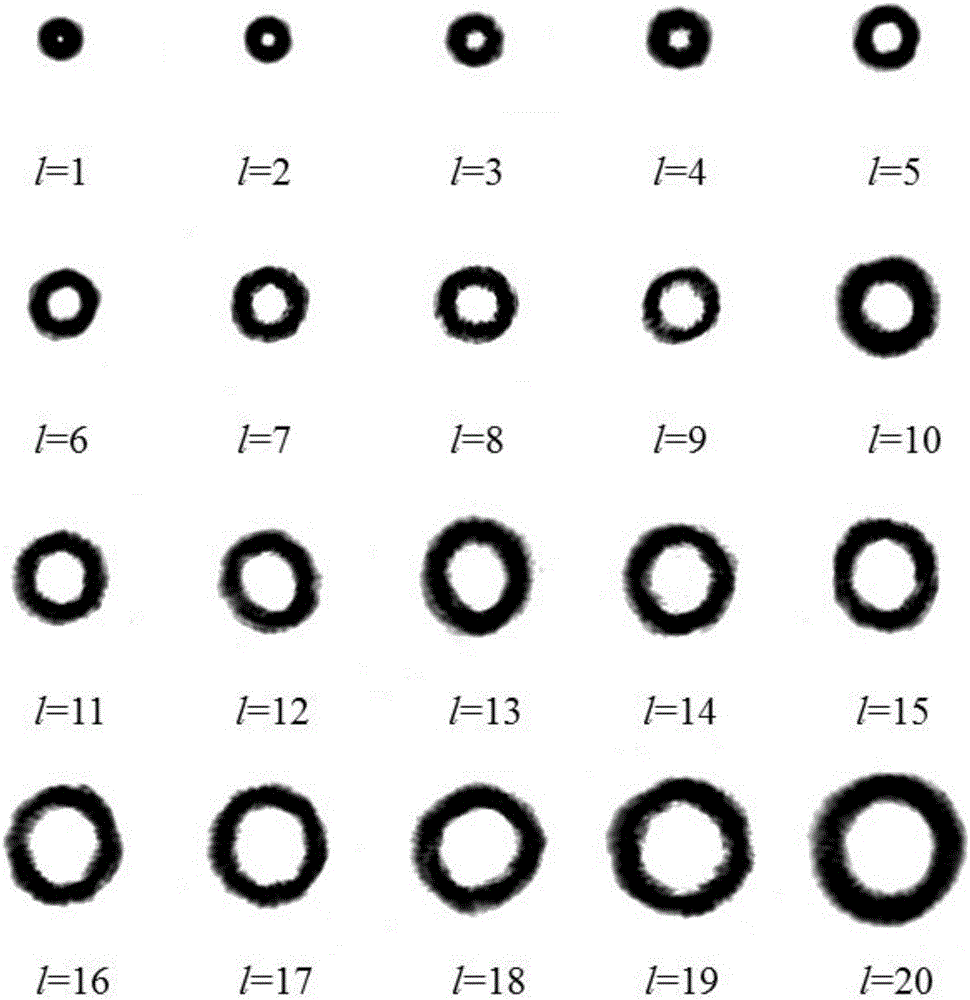

[0025] 2) Install a CCD camera in the laser output direction to monitor the spot pattern of the output laser, adjust the lateral position of the end face, and move a certain circular microhole on the laser output end face to the center of the laser beam until the A circular spot pattern is displayed in the CCD camera, and the generated laser beam has a specific order LG 0l The vortex beam of the mode, wherein l is a non-zero integer, is called the order of the vortex beam;

[0026] 3) Fine-tune the lateral position of the circular microhole or swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com