Remote control circuit board test system and method

A testing system and circuit board technology, applied in electronic circuit testing, instruments, measuring electricity, etc., can solve problems such as low testing efficiency, and achieve the effects of improving testing efficiency, improving accuracy, and reducing signal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

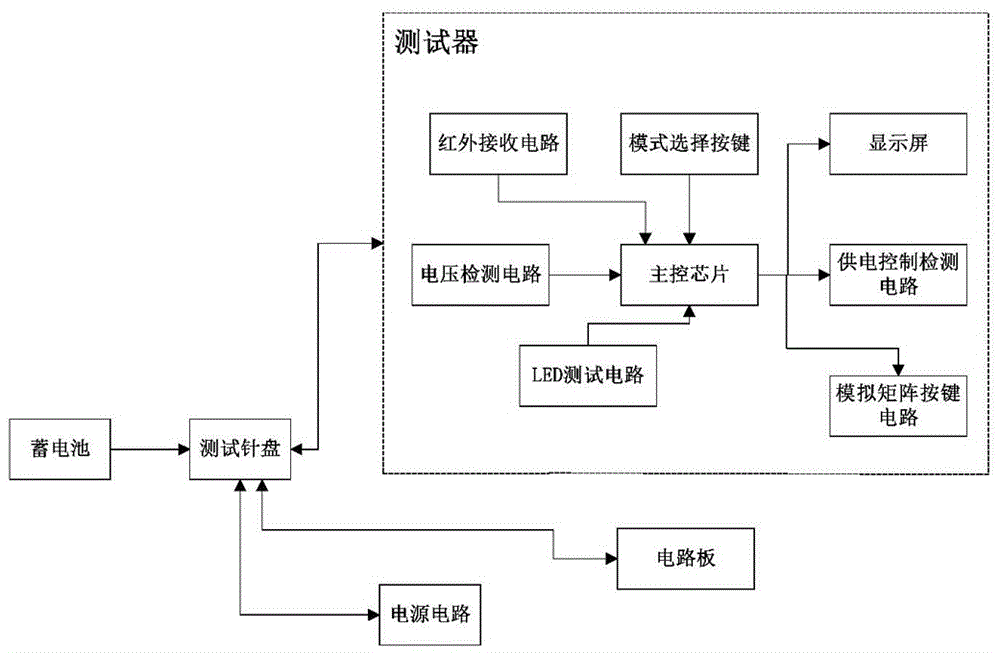

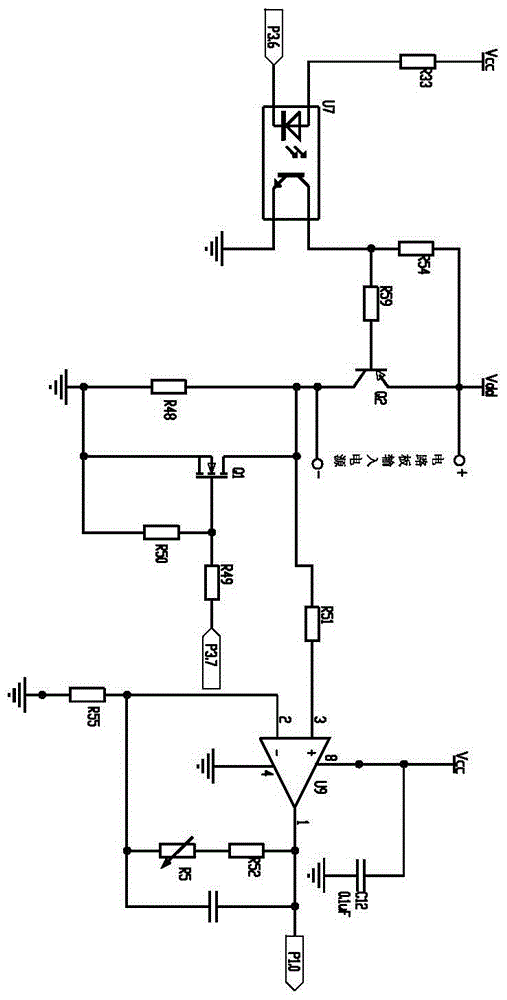

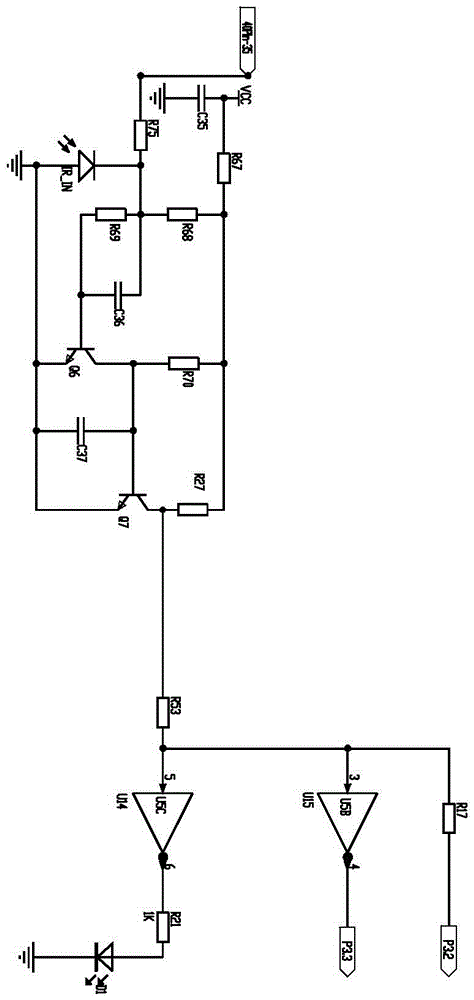

[0028] Such as Figure 1 to Figure 9 A test system for a circuit board of a remote control shown includes a tester, a liftable test dial and several fixed test positioning fixtures for clamping the circuit board. The test dial is provided with several The test points of each circuit board correspond to the test needles one by one. The test needle plate is set directly above the test positioning fixture. The test needle transmits the test signal corresponding to the test point of the circuit board to the tester through the test needle plate. The tester includes the main control Chip U8, power supply circuit, voltage detection circuit, power supply control power consumption detection circuit, alarm circuit, analog matrix button circuit and display screen, power supply circuit for power supply control power consumption detection circuit, alarm circuit, display screen, main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com