Heat-insulation slag-filtering groove

A technology of filter slag and partition plate, which is applied in the field of smelting, can solve problems such as uneven molten water, waste, and unclean scum removal, and achieve the effect of improving slag removal efficiency and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

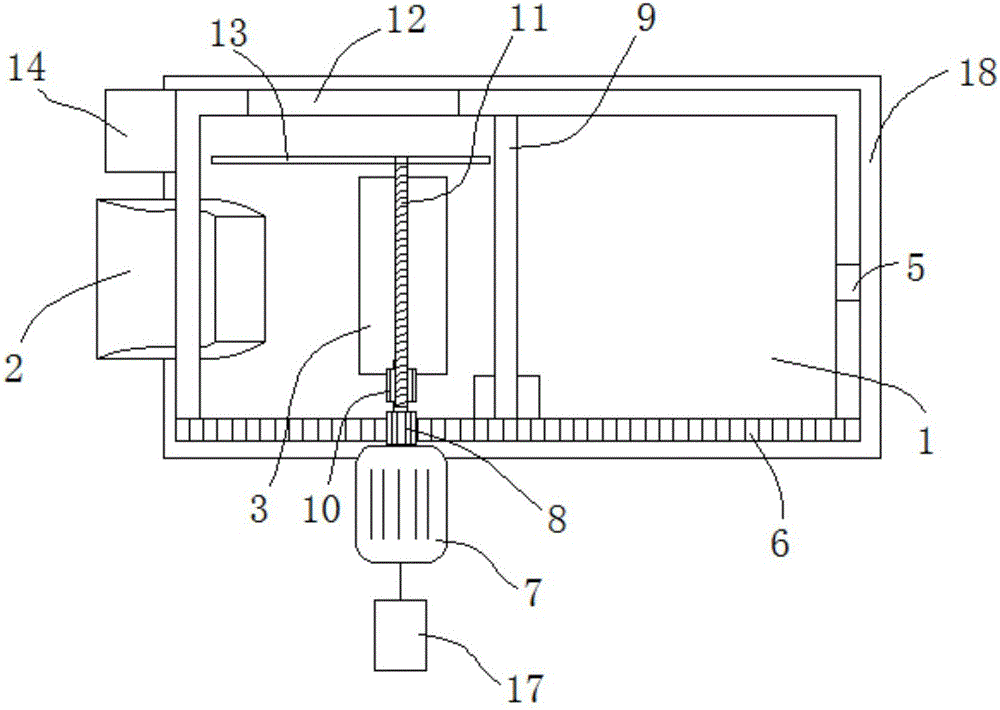

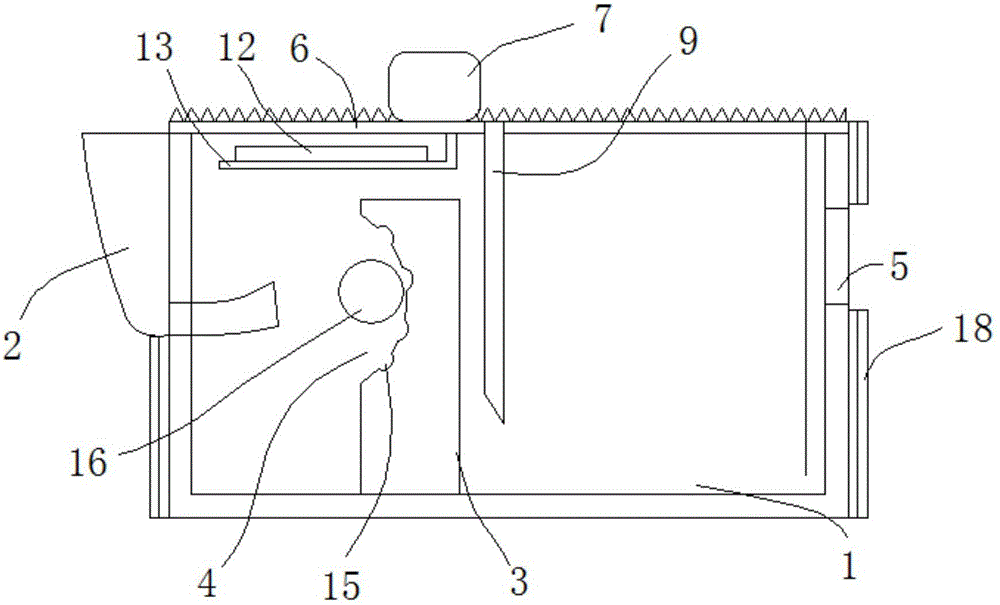

[0024] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

[0025] like figure 1 and figure 2 As shown, a heat-insulating filter residue tank includes a tank body 1, a water receiving pipe 2 is arranged on an outer wall of the tank body 1, and one end of the water receiving pipe 2 extends into the tank body 1, and the tank body 1 A diversion device 3 for changing the flow direction of molten water is provided in the body 1 near the water receiving pipe 2, and an arc groove 4 is provided at one end of the diversion device 3 near the water receiving pipe 2; the groove body 1 A drain port 5 is provided on the side wall away from the water receiving pipe 2;

[0026] The upper end of the side wall of the tank body 1 is provided with a laterally movable rack 6, one side of the tank body 1 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com