Stirring machine mechanical seal shaft sleeve leakage elimination device

A technology for mixers and mechanical seals, which is applied to mixer accessories, engine seals, mixers, etc., and can solve the problems of leakage and corrosion of tower walls, damage of mechanical seal shaft sleeve seal O-rings, leakage, and large losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

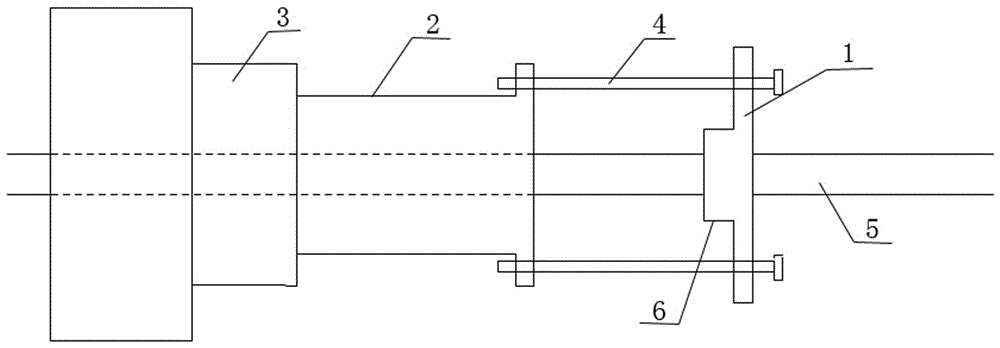

[0010] The leakage elimination device of the shaft sleeve of the mixer machine includes a disc 1 and a pipe body 2. A circular hole with a diameter larger than the shaft of the mixer is processed in the center of the disc, and a bolt hole located on the same circle is also processed on the disc.

[0011] In the leak-proof device for the shaft sleeve of the mixer, the disk 1 is also processed with a boss 6, and the center of the boss 6 is processed with a through hole with a diameter larger than the mixer shaft.

[0012] In the specific implementation, (1) Find a pipe body with a length of 150mm, use a 20mm thick steel plate to draw a circle with a diameter larger than the diameter of the pipe body 60mm, cut along the drawn line to make a disc, and then use the disc to circle Draw a circle with a diameter 30mm larger than the diameter of the pipe body with the point as the center, take 4 points symmetrically on the drawn line, draw 4 bolt holes of Φ18mm, and process a boss on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com