Reactive polymer for drilling plugging and preparation method thereof

A polymer and reaction technology, applied in the field of polymers, can solve the problems of repeated leakage, small water expansion of expansion plugging agent, and mutual separation of components, so as to achieve improved performance, strong pertinence, and avoid implosion and coagulation gelling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

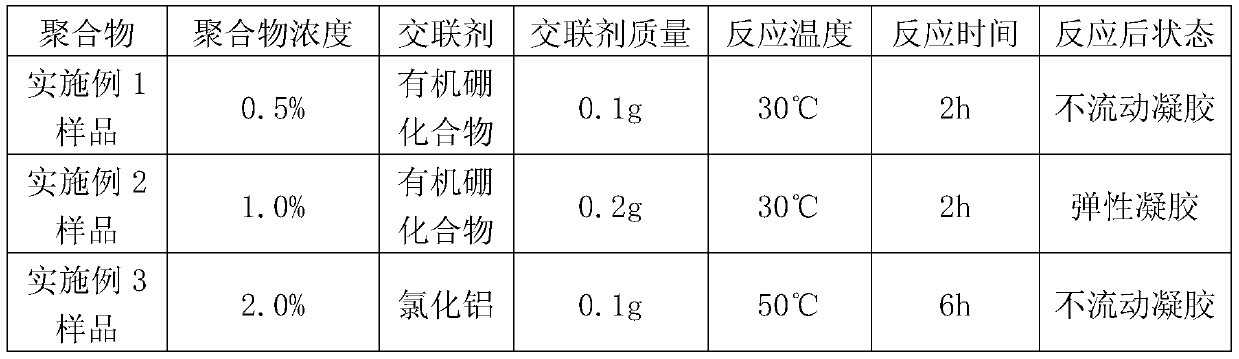

Examples

Embodiment 1

[0026] Gross weight of the present invention is 100g, and it is mainly formed by the raw material polymerization of following mass percent:

[0027] The first raw material is 62%, that is, 62g; the first raw material is acrylamide;

[0028] The second raw material is 37.5%, that is, 37.5g; the second raw material is hydroxyethyl methacrylate;

[0029] The initiator is 0.25%, that is, 0.25g; the initiator is an oxidizing agent, specifically sodium persulfate;

[0030] The reducing agent is 0.25%, that is, 0.25g; the reducing agent is sodium bisulfite.

[0031] The preparation method of the present invention comprises the following steps:

[0032] Step 1. Prepare each raw material according to the polymer formula quantity, and prepare dissolved water. The mass ratio of the polymer formula quantity to dissolved water is 1:2.5, that is, the water is 250g; prepare the reaction apparatus;

[0033] Step 2. Add the first raw material into the dissolved water, prepare an aqueous sol...

Embodiment 2

[0038] Gross weight of the present invention is 100g, and it is mainly formed by the raw material polymerization of following mass percent:

[0039] The first raw material is 67.5%, that is, 67.5g; the first raw material is a mixture of acrylamide and sodium acrylate, and the mass ratio of the two is 2:1;

[0040] The second raw material is 32%, i.e. 32g; the second raw material is hydroxyethyl acrylate;

[0041] The initiator is 0.35%, that is, 0.35g; the initiator is an oxidizing agent, specifically ammonium persulfate;

[0042] The reducing agent is 0.15%, that is, 0.15g; the reducing agent is sodium sulfite.

[0043] The preparation method of the present invention comprises the following steps:

[0044] Step 1. Prepare each raw material according to the polymer formula quantity, and prepare dissolved water. The mass ratio of the polymer formula quantity to the dissolved water is 1:3, that is, the water is 300g; prepare the reaction apparatus;

[0045] Step 2. Add the fi...

Embodiment 3

[0050] Gross weight of the present invention is 100g, and it is mainly formed by the raw material polymerization of following mass percent:

[0051] The first raw material is 80%, that is, 80g; the first raw material is a mixture of acrylamide, acrylic acid and sodium acrylate, and the mixing mass ratio of the three is 1:1:1;

[0052] The second raw material is 19%, that is, 19g; the second raw material is a mixture of hydroxyethyl acrylate, vinyl acetate and hydroxyethyl methacrylate, and the mixing mass ratio of the three is 1:1:1;

[0053] The initiator is 0.5%, that is, 0.5g; the initiator is an oxidizing agent, specifically ammonium persulfate;

[0054] The reducing agent is 0.5%, that is, 0.5g; the reducing agent is sodium bisulfite.

[0055] The preparation method of the present invention comprises the following steps:

[0056] Step 1. Prepare each raw material according to the polymer formula quantity, and prepare dissolved water. The mass ratio of the polymer formula ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com