Special bio-organic fertilizer suitable for maca in plateau regions and preparation method of fertilizer

A bio-organic fertilizer and regional technology, applied in the direction of organic fertilizer, fertilizer mixture, application, etc., can solve the problems of organic matter loss, bio-organic fertilizer loss of fertilizer efficiency, and inability to industrialize production and application, and achieve high efficiency and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

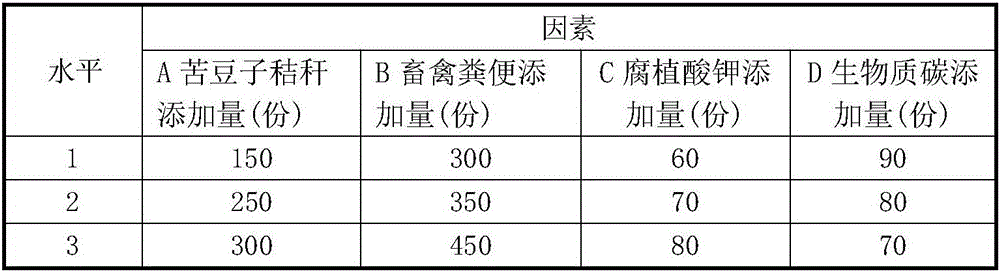

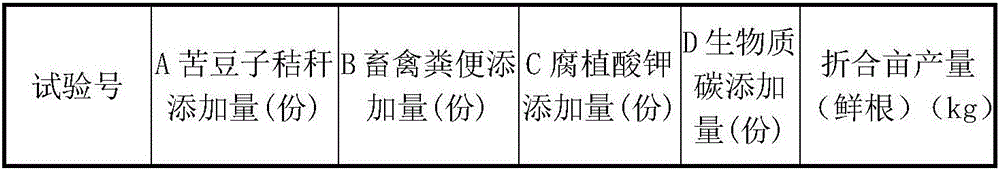

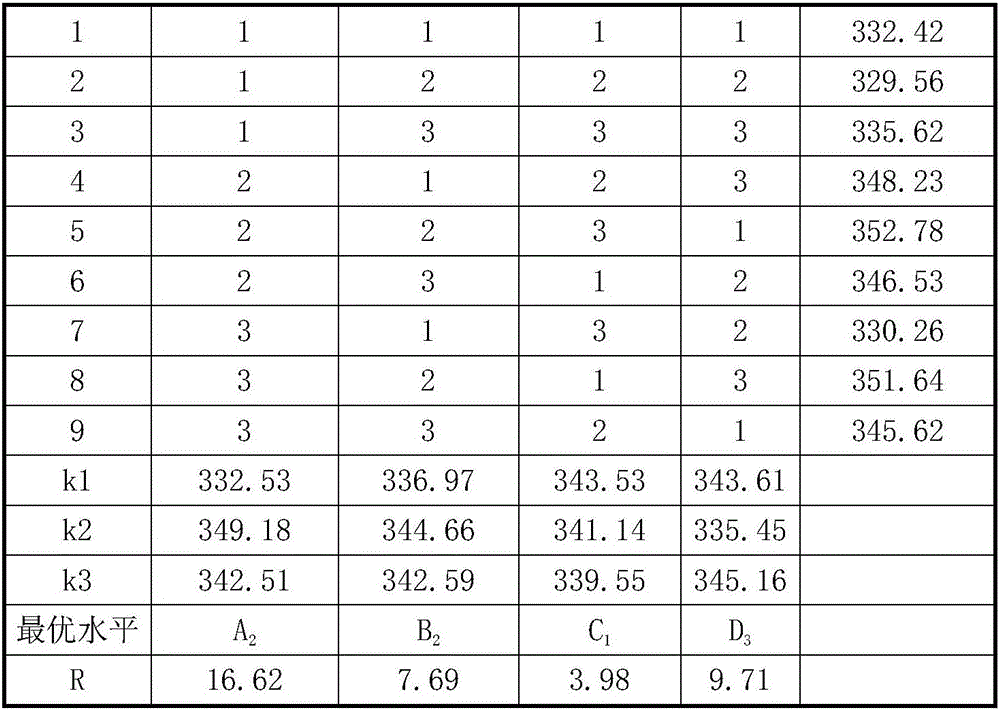

Method used

Image

Examples

Embodiment 1

[0022] A special bio-organic fertilizer suitable for maca in plateau areas, including 250kg of bitter bean straw, 350kg of livestock and poultry manure, 60kg of ammonium sulfate, 60kg of potassium humate, 70kg of biomass carbon, 20kg of organic material decomposing agent, and zinc sulfate by weight 3kg, ferrous sulfate 5kg, water 30kg. Among them, the stalk of Sophora sophora is the remaining part after harvesting the seeds of Sophora sophora. Biomass carbon is obtained by pyrolysis of cotton stalks, corn stalks, wheat stalks, and grape branches at 495°C under anoxic conditions. The decomposing agent for organic materials contains release line Bacteria, Saccharomyces and Photosynthetic Bacteria.

Embodiment 2

[0024] First mix cotton stalks, corn stalks, wheat stalks, and grape branches in a weight ratio of 3:2:1:1, and then pyrolyze them under anoxic conditions at 450°C to obtain biomass carbon. The organic material decomposing agent of the bacterial strain is used for standby. After pulverizing 150kg of bitter bean straw, mix it with 300kg of livestock and poultry manure and 50kg of ammonium sulfate according to the proportion, add 10kg of water and 10kg of organic material decomposing agent, stir and mix evenly, and control the moisture content of the material at 50%. Hold it into a ball, loosen it and disperse it. Put the mixed material into the aerobic fermentation tank for 20 days of fermentation. The fermentation temperature is controlled below 55°C. When the fermentation temperature is higher than 55°C, turn the pile to cool down. After the decomposed material is mixed with 50kg potassium humate, 50kg biomass carbon, 2kg zinc sulfate, and 2kg ferrous sulfate, it is crushed a...

Embodiment 3

[0026] First mix cotton stalks and corn stalks at a weight ratio of 2:1, and then pyrolyze them to obtain biomass carbon at 430°C under anoxic conditions, and then purchase organic material decomposing agents containing actinomycetes, yeasts and photosynthetic bacteria for future use. After pulverizing 250kg of Sophora sophora stalks, mix them with 350kg of livestock and poultry manure and 60kg of ammonium sulfate in proportion, add 30kg of water and 20kg of organic material decomposing agent, stir and mix evenly, control the moisture content of the material at 51%, and put the mixed material into The aerobic fermentation tank is fermented for 28 days, and the fermentation temperature is controlled below 55°C. When the fermentation temperature is higher than 55°C, the compost is turned over to cool down. After zinc and 5kg ferrous sulfate are mixed evenly, they are pulverized and dried to a material size of 3 mm with an organic fertilizer pulverizer to obtain a special bio-orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com