Composite magnetized flocculation thickening device

A composite and flocculation technology, applied in the direction of flocculation/sedimentation water/sewage treatment, chemical instruments and methods, magnetic field/electric field water/sewage treatment, etc., can solve the problem of large power consumption in low-concentration tailings transportation, restriction of mine economic benefits, Problems such as high degree of sedimentation turbulence can be achieved to improve the quality of overflow water, improve the recycling rate, and solve the effect of uneven feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

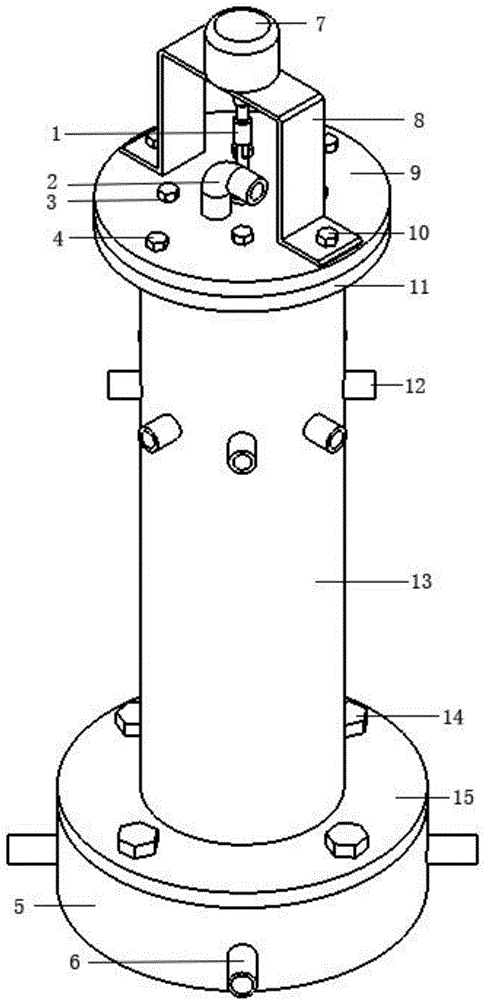

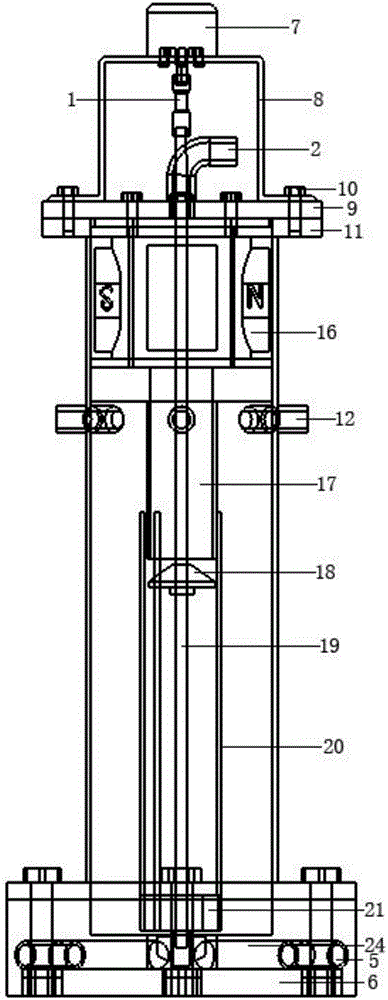

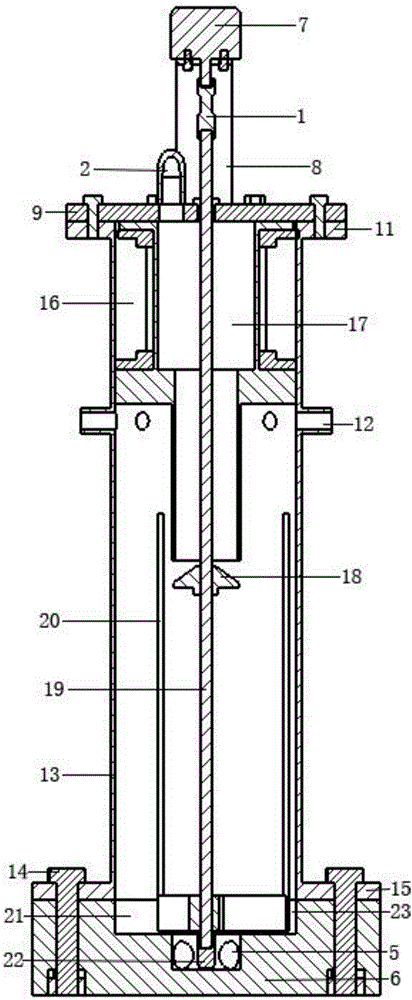

[0043] like Figure 1-4 As shown, a composite magnetized flocculation thickening device includes a feeding system with a uniform feeding function, a magnetization system for magnetizing the slurry, a settling system with a built-in flocculation settling space, and a settling system for diversion and scraping away from sand The driving system, the discharging system for discharging overflow and grit, and the fixing system for fixing and supporting the device,

[0044] The feeding system includes a feeding pipe 2, a central feeding cylinder 17 and a distribution tray 18;

[0045] The magnetization system includes at least one SN electronically controlled magnetic pole pair 16;

[0046] The settling system at least includes a settling cylinder 13;

[0047] The drive system at least includes a motor 7, a shaft coupling 1, a central shaft 19, a variable-diameter scraper 21 and a fixed-diameter scraper 22;

[0048] The fixing system includes at least an end cover 9 and a base 6; ...

Embodiment 2

[0072] The difference between this embodiment and Embodiment 1 is that, in the above technical solution, the magnetization system includes an SN electronically controlled magnetic pole pair 16 .

[0073] Further, in the above technical solution, the discharge system includes an overflow pipe 12 and an underflow pipe 5 ; an underflow port 24 is provided on the base 6 .

[0074] Further, in the above technical solution, the fixing system further includes a motor bracket 8 ; the motor bracket 8 for fixing the motor 7 is connected to the top of the end cover 9 through third bolts 10 .

[0075] Through the technical solutions described in the above embodiments, the composite magnetized flocculation thickening device of the present invention can magnetize the fed slurry by configuring the magnetization system in the variable-diameter central feeding cylinder, thereby improving the flocculation and sedimentation rate of fine particles. , the conical distribution plate configured toge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com