W-shaped exhaust gasket structure

A technology of air cushion and exhaust port, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of increasing use cost, reducing service life, difficult to restore, etc., to meet the use requirements, long service life, no easily damaged effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

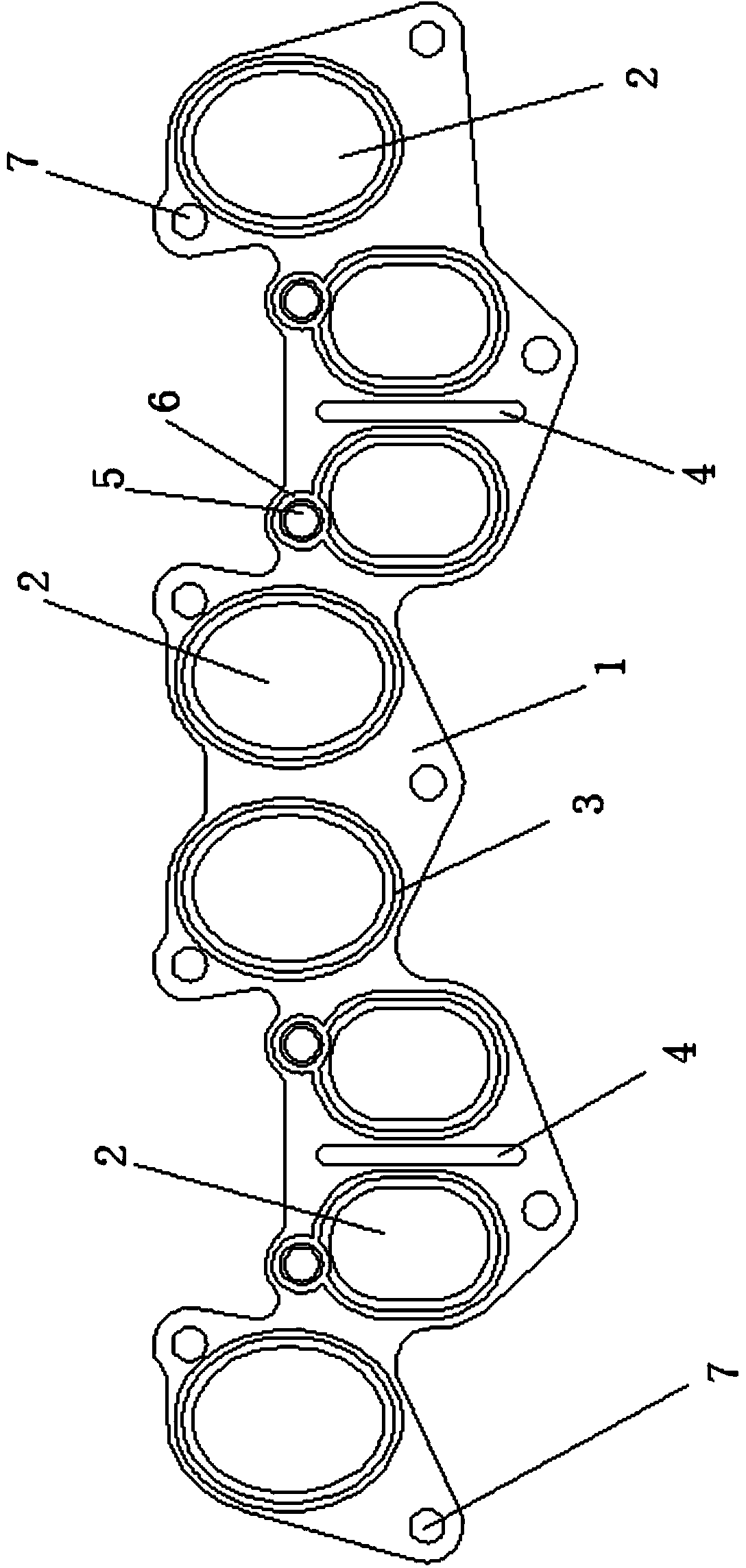

[0009] Referring to the accompanying drawings, a W-shaped exhaust pad structure includes a gasket body 1. There are respectively W-shaped exhaust ports 2 on the gasket body 1, and outwardly protruding arcs are respectively provided at the exhaust ports 2. Shaped sealing rib 3, and a waist-shaped positioning hole 4 is provided between the two exhaust holes at the bottom of the W shape, and an adjustment hole 5 is provided above the waist-shaped positioning hole 4, and the adjustment hole 5 is provided with an arc-shaped seal. The buffer ribs 6 with the ribs 3 opposite to each other, the outer edge of the buffer ribs 6 intersects with the arc-shaped sealing ribs 3 , and the gasket body 1 is also provided with installation holes 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com