Split damping cart and damping method

A separate type and material cart technology, applied in the direction of trolleys, multi-axis trolleys, trolley accessories, etc., can solve the problems of inability to take into account the use of light materials, fail to meet the shock absorption requirements, increase production costs, etc., and achieve a significant shock absorption effect , Improve the shock absorption effect and save production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

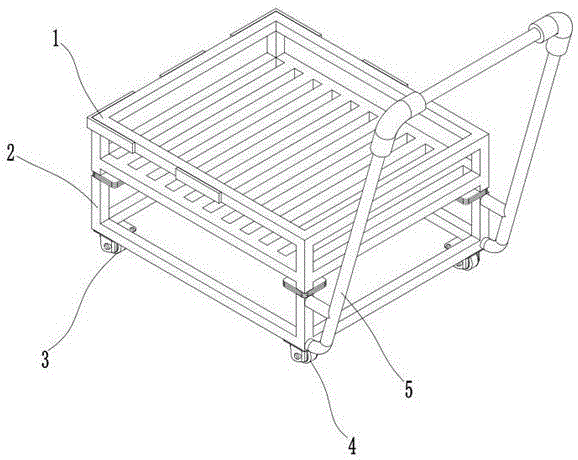

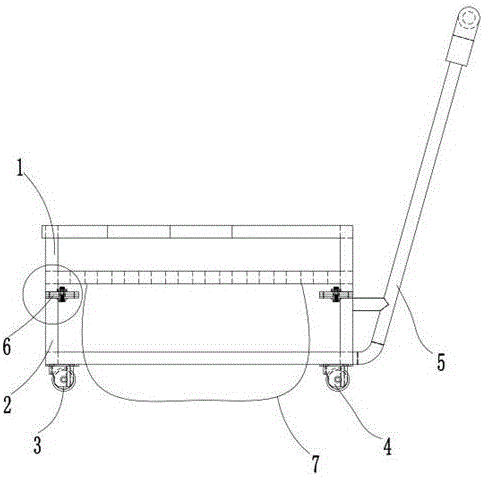

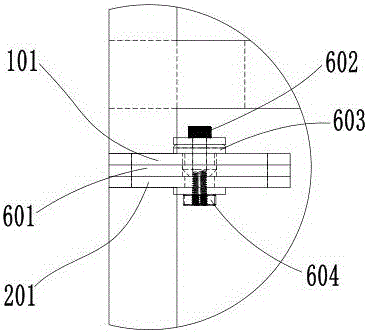

[0039] Such as Figure 1 to Figure 5 As shown, the separate shock-absorbing push car of this embodiment is used to transport the lead frame products that have been wired in the front section, including the upper frame 1 and the chassis frame 2, and the upper frame and the chassis frame are detachably connected, and The connection structure of the two is a shock-absorbing connection structure 6, and the shock-absorbing connection structure 6 includes an elastic pad arranged between the upper frame 1 and the chassis frame 2, so that the upper frame 1 and the chassis frame 2 are in contact with each other through the elastic pad. .

[0040] Further, the elastic pad in this embodiment is a shock-absorbing silicone pad 601 . The shock-absorbing silicone pad is characterized by both high elastic state and high viscous state. The elasticity of rubber is produced by the change of its coiled molecular conformation. This coiled long-chain molecular structure and the weaker secondary mo...

Embodiment 2

[0043] Such as Figure 1 to Figure 5 As shown, according to the detached shock-absorbing push cart described in Embodiment 1, this embodiment also includes connectors that pass through the elastic pad and are connected to the upper frame 1 and the chassis frame 2 respectively, and the connectors are provided with The elastic sleeve makes the connector contact with the upper frame 1 and the chassis frame 2 respectively through the elastic sleeve. The connecting piece is generally a metal piece. Since the connecting piece will directly contact the chassis frame and the upper frame, in order to further reduce shock, an elastic sleeve is set to cover the connecting piece, and the vibration of the chassis frame received by the connecting piece is eliminated through the elastic sleeve. , to prevent the vibration of the wheel from being transmitted to the upper frame through the connecting piece, and attenuate the energy transmitted from the vibration generated by the wheel to the up...

Embodiment 3

[0047] Such as Figure 1 to Figure 5 As shown, according to the detached shock-absorbing push car described in Embodiment 1 or Embodiment 2, the upper frame 1 of this embodiment includes a support plate 102 for supporting materials, and a stop frame is provided above the support plate 102 Ring 104, a connection pressure plate 101 for connecting with the chassis frame 2 is provided below the support plate 102. A retainer ring is set above the support plate. After placing materials on the support plate, the material can be prevented from falling through the retainer ring, and the structure connecting the upper frame and the chassis frame is set to connect the pressure plate. The plate-like structure is conducive to The elastic pad is placed to increase the elastic damping area.

[0048] Specifically, such as Figure 4 As shown, the support plate 102 is also provided with limit grooves 1021 at intervals, which is convenient for the placement of frame products, and cooperates wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com