Automatic traction device

A traction device and automatic technology, applied in the direction of traction connectors, transportation and packaging, vehicle parts, etc., can solve the problems of difficult alignment connection, high labor intensity, poor safety, etc., to avoid misoperation, exquisite structure, and easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

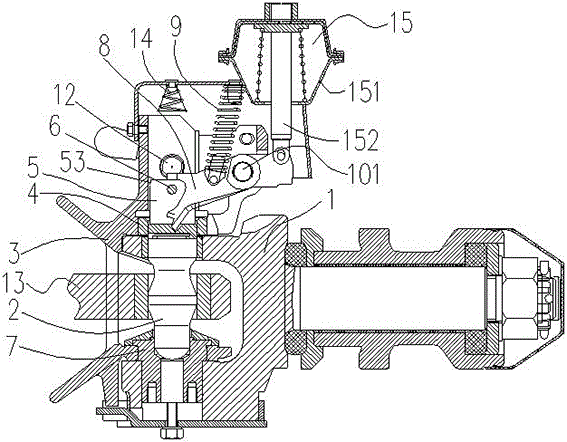

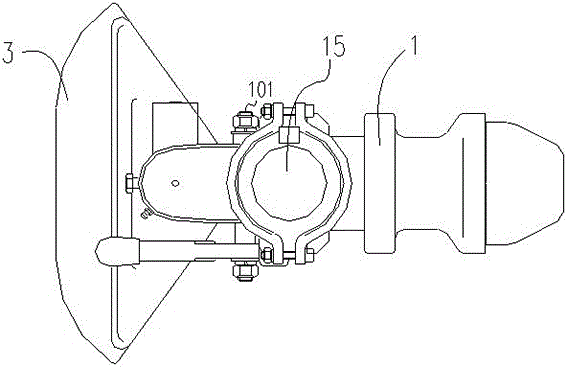

[0033] Example: such as Figure 1 to Figure 3 As shown, a kind of automatic traction device comprises draw bar 1, drag pin 2 and guide shell 3, and guide shell 3 is connected with draw bar 1; Drag pin 2 is placed in the hole of guide shell 3, and drag pin 2 from Go through the guide housing 1, the guide sleeve 4, the trailer ring 13 and the guide sleeve 7 sequentially from top to bottom; Image 6 As shown, the present invention also includes a limit pin assembly 12. The limit pin assembly 12 includes a drag pin locking shaft 121 and a drag pin locking spring 123. The drag pin locking shaft 121 is arranged in the horizontal hole of the guide housing 3 Inside, the drag pin locking spring 123 is located at the rear end of the drag pin locking shaft 121, and the front end of the drag pin locking shaft 121 has a tapered top 1211; figure 1 As shown, the upper corner of the drag pin 2 is provided with a first guide bevel 53 corresponding to the tapered top 1211; Figure 7 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com