Dosing system

A technology of liquid dispensing system and liquid dispensing tank, which is applied in the direction of mixer accessories, dissolving, mixing machines, etc., can solve the problems of poor cleaning and disinfection process, low accuracy of ingredients, and only manual control, etc., to reduce bacterial residues and structure Simple, cross-contamination prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

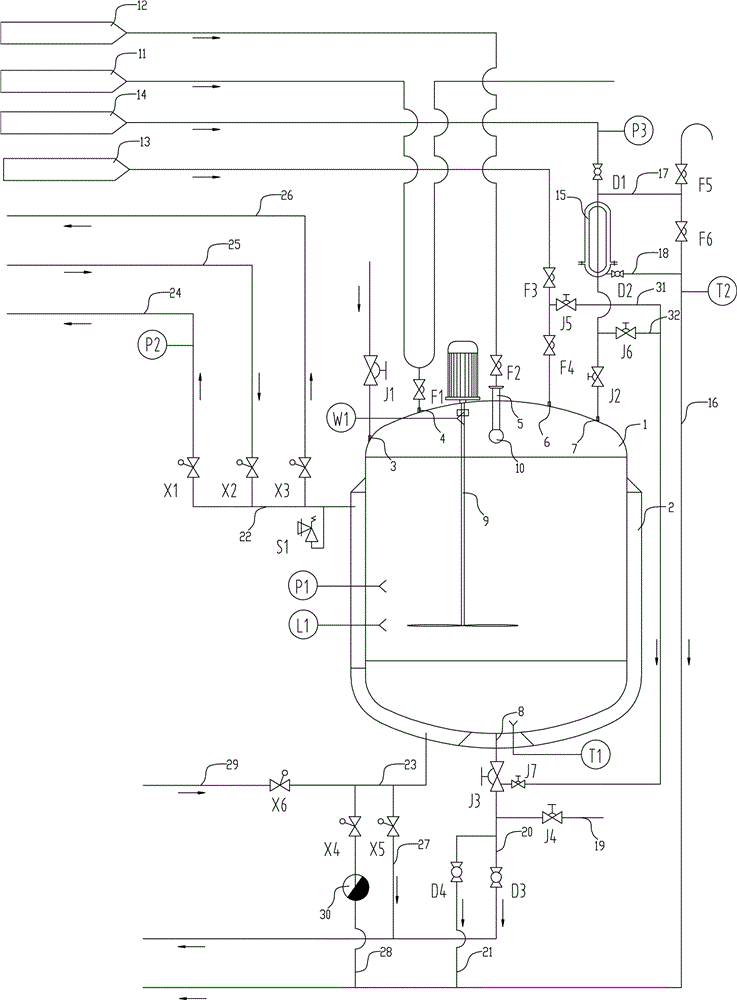

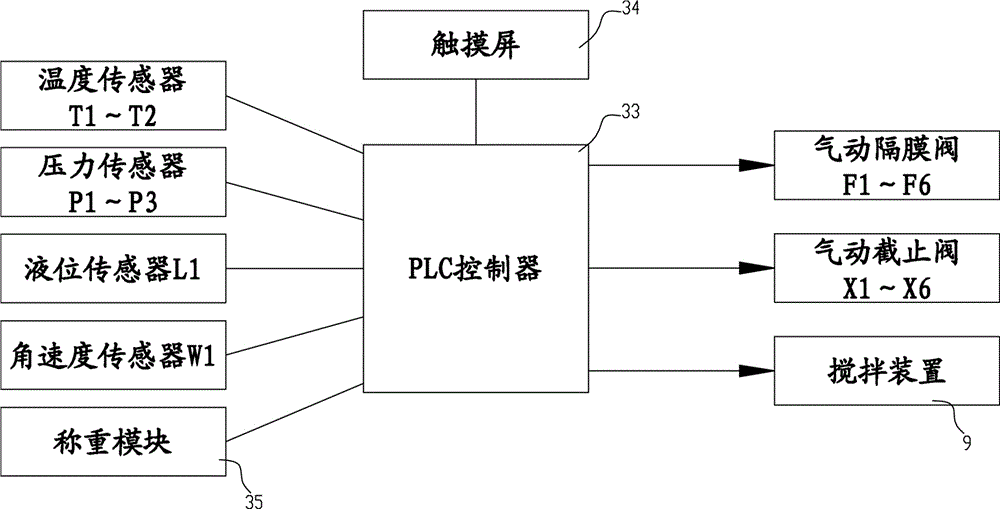

[0016] see figure 1 , the present invention has a liquid distribution tank 1, the outer wall of the liquid distribution tank 1 is provided with a jacket 2, the jacket 2 is used to heat or cool the liquid distribution tank 1, and the liquid distribution tank 1 is provided with a feed port 3, a batching Inlet 4, cleaning port 5, pure steam inlet 6, pure air inlet 7 and material outlet 8, mixing device 9 and cleaning device 10 are installed in liquid distribution tank 1; especially: on the external pipeline of feeding port 3 Equipped with a manual diaphragm valve J1; the batching port 4 is connected to the batching device 11 through the pneumatic diaphragm valve F1 and the external pipeline; the cleaning port 5 is internally connected to the cleaning device 10, and connected to the cleaning liquid device 12 through the pneumatic diaphragm valve F2 and the external pipeline; The steam inlet 6 is connected to the pure steam generator 13 through pneumatic diaphragm valves F3, F4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com