Steamer for cooking pigskin jelly sausages

A technology for frozen pigskin and sausages, which is applied to the field of steaming utensils for cooking frozen pigskin sausages, can solve the problems of affecting the taste, cannot be stored for a long time, greasy, etc., and achieves the effects of convenient disassembly and assembly, stable filling and molding, and smooth and tender taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

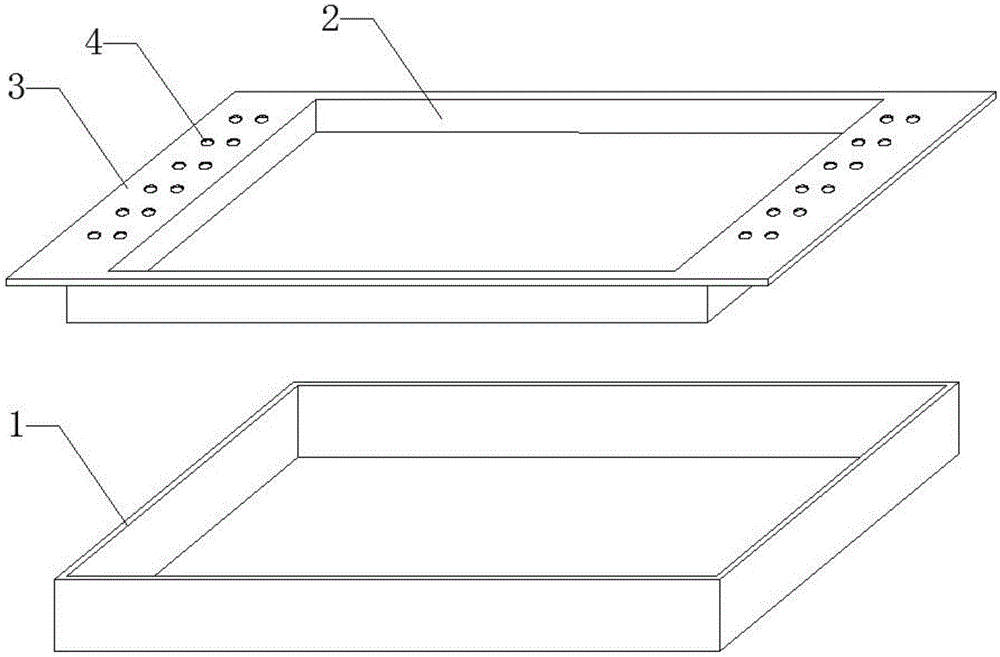

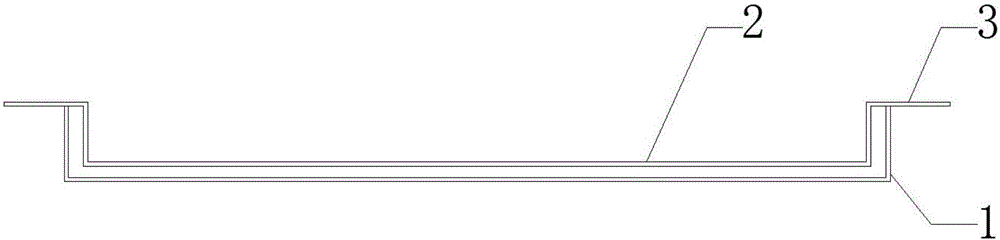

[0019] Such as figure 1 , 2 As shown, a steamer for cooking frozen pork skin sausages includes a tray 1 and a steaming plate 2, the tray 1 is square, the steaming plate 2 is placed on the tray 1, and the upper part of the side wall of the steaming plate 2 is provided with A baffle plate 3 extending outward, and a through hole 4 is arranged on the baffle plate 3 .

[0020] Preferably, a cavity is formed between the tray 1 and the steaming tray 2 .

[0021] Preferably, the baffle 3 is in a horizontal direction.

[0022] Preferably, the outer front and rear side walls of the steaming tray 2 form an interference fit with the inner front and rear side walls of the tray 1, the left and right sides of the side walls of the steaming tray 2 are provided with baffles 3, and the through holes 4 are uniformly and densely distributed in the baffles. plate 3.

Embodiment 2

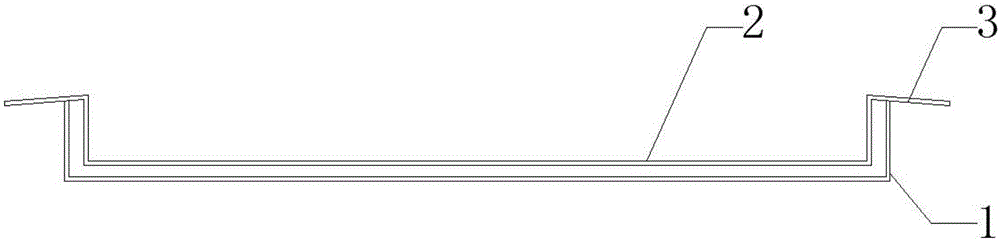

[0024] Such as image 3 As shown, a steamer for cooking frozen pork skin sausages includes a tray 1 and a steaming plate 2, the tray 1 is square, the steaming plate 2 is placed on the tray 1, and the upper part of the side wall of the steaming plate 2 is provided with A baffle plate 3 extending outward, and a through hole 4 is arranged on the baffle plate 3 .

[0025] Preferably, a cavity is formed between the tray 1 and the steaming tray 2 .

[0026] Preferably, the baffle 3 is inclined, and the outer edge of the baffle 3 is lower than the inner edge.

[0027] Preferably, the outer front and rear side walls of the steaming tray 2 form a clearance fit with the inner front and rear side walls of the tray 1, and the side walls of the steaming tray 2 are provided with baffles 3 around, and the through holes 4 are uniformly and densely distributed on the baffles 3 .

[0028] Preferably, the specific method for making pigskin jelly sausage using the steamer includes the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com