Film sheet used for cover plate and manufacturing method thereof

A production method and diaphragm technology are applied in the field of diaphragms for cover plates and their preparation, which can solve the problems of long coating time, high cost, and large color fluctuation range, and achieve consistency, low processing cost, and high coating quality. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

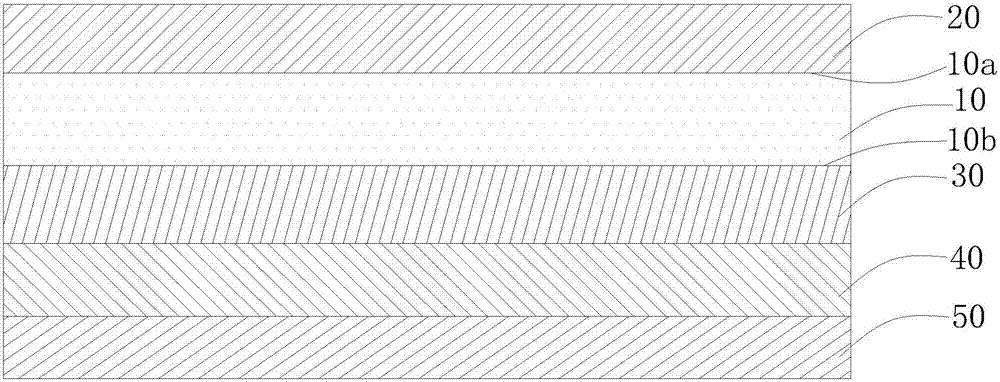

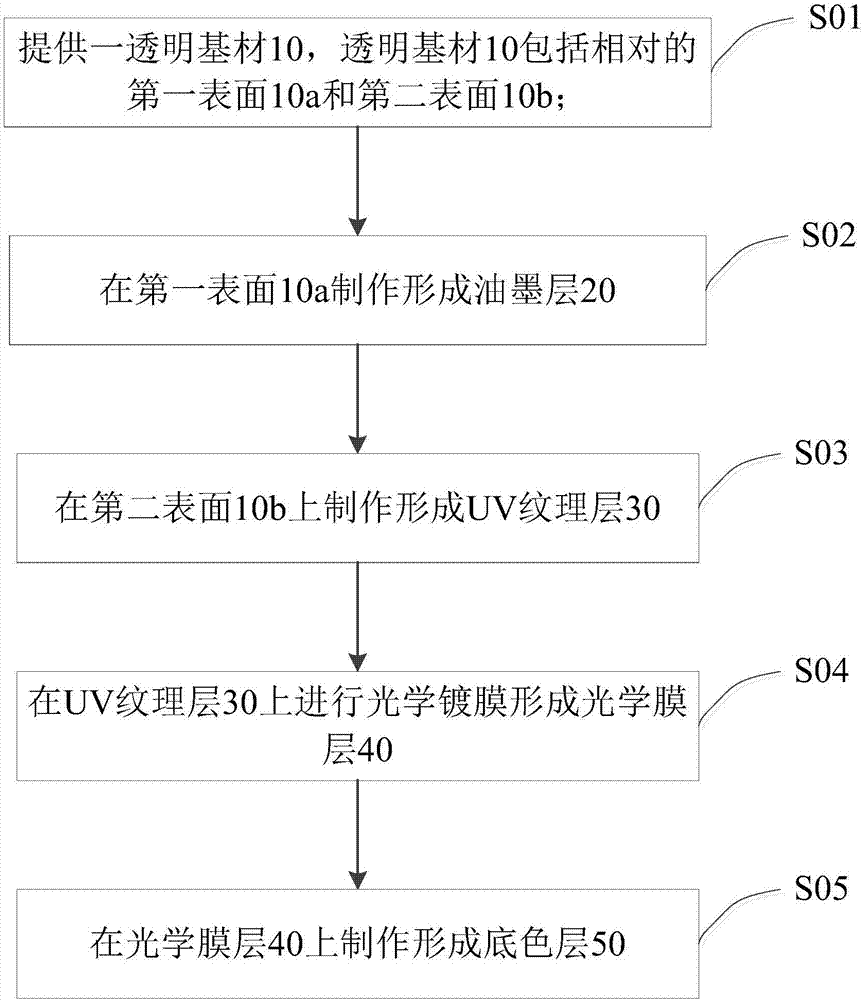

[0039] like figure 1 As shown, the film for the cover plate provided by the embodiment of the present invention includes a transparent substrate 10, an ink layer 20, a UV texture layer 30, and an optical film layer 40. The transparent substrate 10 includes a first surface 10a and a first surface On the second surface 10b opposite to 10a, the ink layer 20 is arranged on the first surface 10a, the UV texture layer 30 is arranged on the second surface 10b, and the optical film layer 40 is arranged on the UV texture layer 30, wherein the ink layer 20 is light-transmitting colored layer, and the optical film layer 40 is a reflective layer. In order to ensure the color effect of the film, a base color layer is arranged on the optical film layer 40 .

[0040] The above-mentioned ink layer 20 is pasted on the glass cover, and the ink layer can weaken the appearance defects after the optical coating, such as particles and dust spots; the simple color optical coating realizes the color...

Embodiment 2

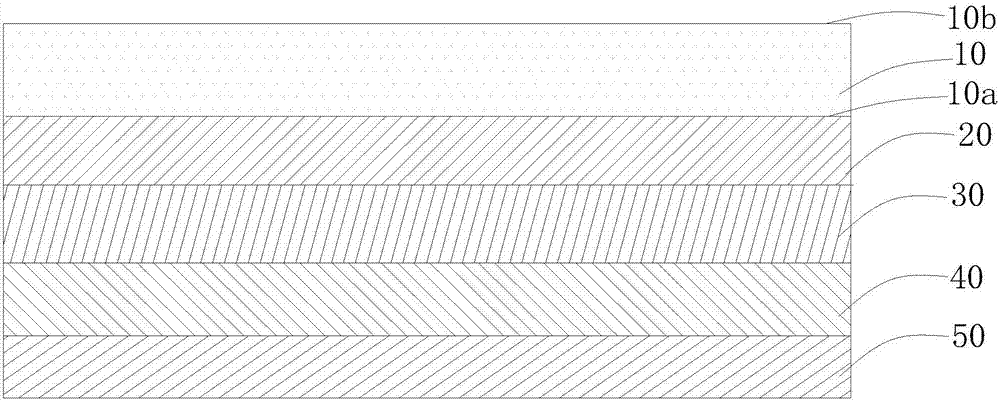

[0053] like image 3 As shown, the difference between the film of Example 2 and Example 1 is that the UV texture layer 30 is disposed on the ink layer 20, that is, the second surface 10b of the transparent substrate 10 is not treated.

[0054] Figure 4 Shows the flow chart of the diaphragm manufacturing process in this embodiment 2, wherein, step S01', step S02', step S04', step S05' are respectively the same as step S01, step S02, step S04, step S05 in embodiment 1 The same, except that in step S03 ′, the UV texture layer 30 is formed on the ink layer 20 .

[0055] After the diaphragm of the embodiment 2 is manufactured, an adhesive layer can be provided on the base color layer 50, and the diaphragm can be pasted on the plastic cover plate, so that the plastic cover plate has better color and texture effects. Of course, in other implementation manners, optical glue can be disposed on the second surface 10 b of the transparent substrate 10 to stick the film on the glass cov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com