Device for automatic winding adhesive tape on wire harness

A tape and wire harness technology, applied in the field of electromechanical automation, can solve the problems of high input cost and no advantages, and achieve the effects of high work efficiency, convenient operation and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] A device for automatically wrapping tape for wire harness, its structure is as follows figure 1 As shown, including the main frame 8, and the wire harness fixing assembly, the tape winding head 5, the head displacement assembly and the electric control assembly arranged on the main frame 8, and the electric control assembly is respectively connected to the tape winding head 5 and the head displacement assembly The moving parts, including the electric control box 7, the man-machine interface 6, the two-hand control switch 4, etc. The wire harness fixing assembly includes a fixing clip 9 for fixing the wire harness to be wound on the tooling plate 10 of the main frame 8 .

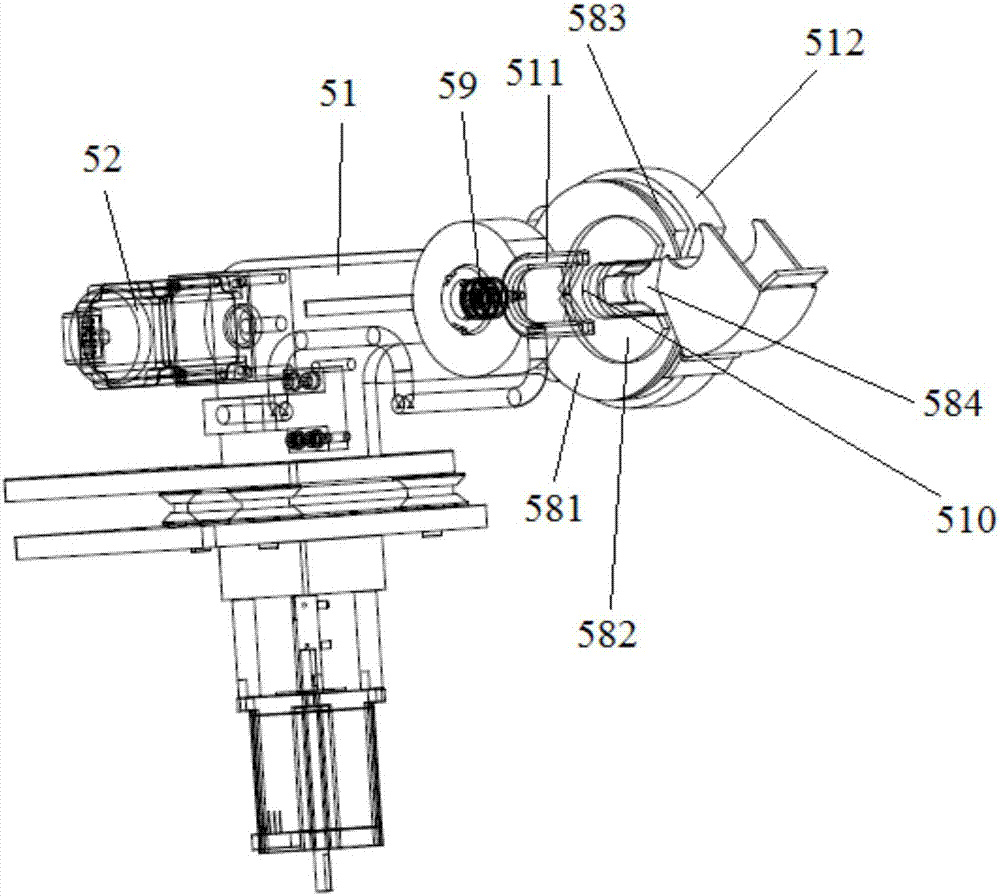

[0038] Tape winding head 5, its structure is as follows image 3 and Figure 4As shown, it includes a main assembly board 51, a rotating motor 52, a transmission assembly, a rotating body unit 58, a tape mounting frame 59 and a material stopper 510. The transmission assembly includes a driving synchr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com