Method for evaluating rolled steel corrosive pitting probability by microcell electrochemistry

A technology for pitting and steel, which is applied in the field of micro-area electrochemical evaluation of steel pitting probability, can solve the problems of inability to quantitatively evaluate the probability of pitting corrosion, etc., to eliminate human interference, reduce pitting evaluation errors, and reduce human errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

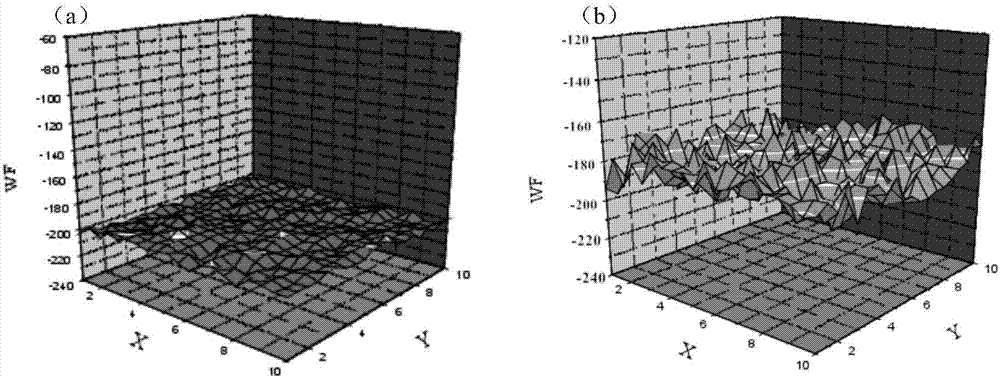

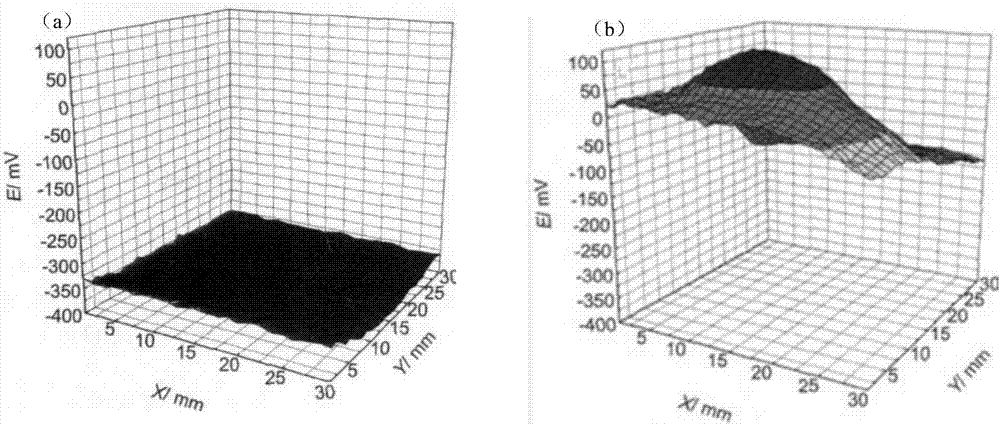

[0029] Cut out square samples with a side length of 90 mm from 304 stainless steel and 15-5PH stainless steel, and divide the sample plate into 30 areas. Put the sample on the SKP test platform, and control the distance between the probe and the sample surface at 100 μm. The frequency of the probe parameters is 80Hz, and the amplitude is 30μm. One of the surface of the sample is the clean state after cleaning with deionized water, which is used to simulate the ordinary atmospheric environment; the other is the state of salt particles after spraying sodium chloride solution and drying, which is used to simulate the marine atmospheric environment.

[0030] The test adopts the surface scanning mode, the scanning step is 50 μm, and the scanning area in each area is 3000 μm×3000 μm, and the two kinds of surfaces are tested respectively. After the test is completed, a three-dimensional potential distribution map is obtained, and the potential difference is calculated. Repeat the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com