Position-adjustable metal plate punching mechanism

A sheet metal, adjustable technology, applied in the field of hardware parts manufacturing equipment, can solve the problems of clamping device thickness requirements, large cutting impact, complex clamping mechanism, etc., to achieve lower installation accuracy requirements, firm and convenient clamping, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

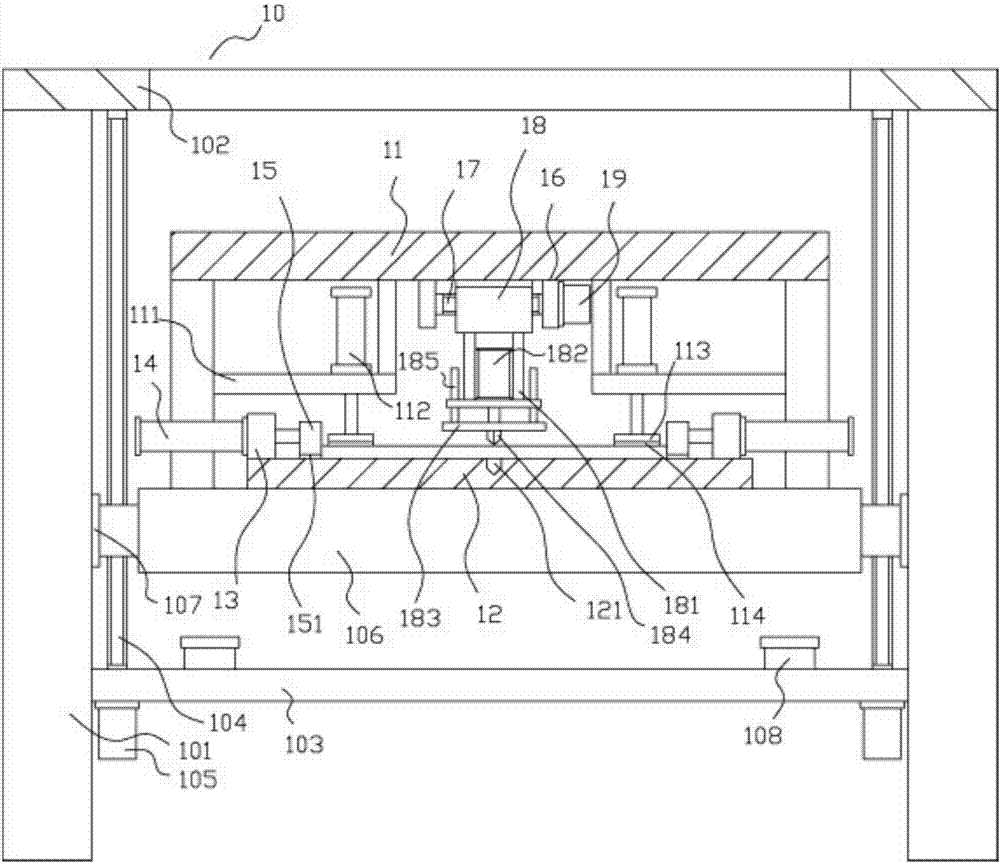

[0017] Example: see figure 1 As shown, a position-adjustable sheet metal punching mechanism includes a frame 10, and the frame 10 includes two main vertical plates 101 and a main top plate 102, and the top ends of the two main vertical plates 101 are fixed on the main On both sides of the bottom surface of the top plate 102, the lower middle plate 103 is fixed on the inner side walls of the two main vertical plates 101, and the two main vertical screw rods 104 are on both sides of the lower middle plate 103, and the bottom ends of the main vertical screw rods 104 are hinged On the lower middle plate 103, the top of the main vertical screw 104 is hinged on the bottom surface of the main top plate 102, and two main adjustment motors 105 are fixed on both sides of the lower middle plate 103, and the output shafts of the main adjustment motors 105 are spline shafts , the spline shaft is inserted into the spline hole at the bottom of the main vertical screw rod 104, the main moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com