Winch load simulation experimental device and method for ocean ship

An experimental device and load simulation technology, applied in the direction of measuring devices, fluid pressure actuating devices, instruments, etc., can solve the problems of bulky equipment, difficult construction, large floor space, etc., and achieve high stability and safety in operation. Practical value and economic value, the effect of convenient and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

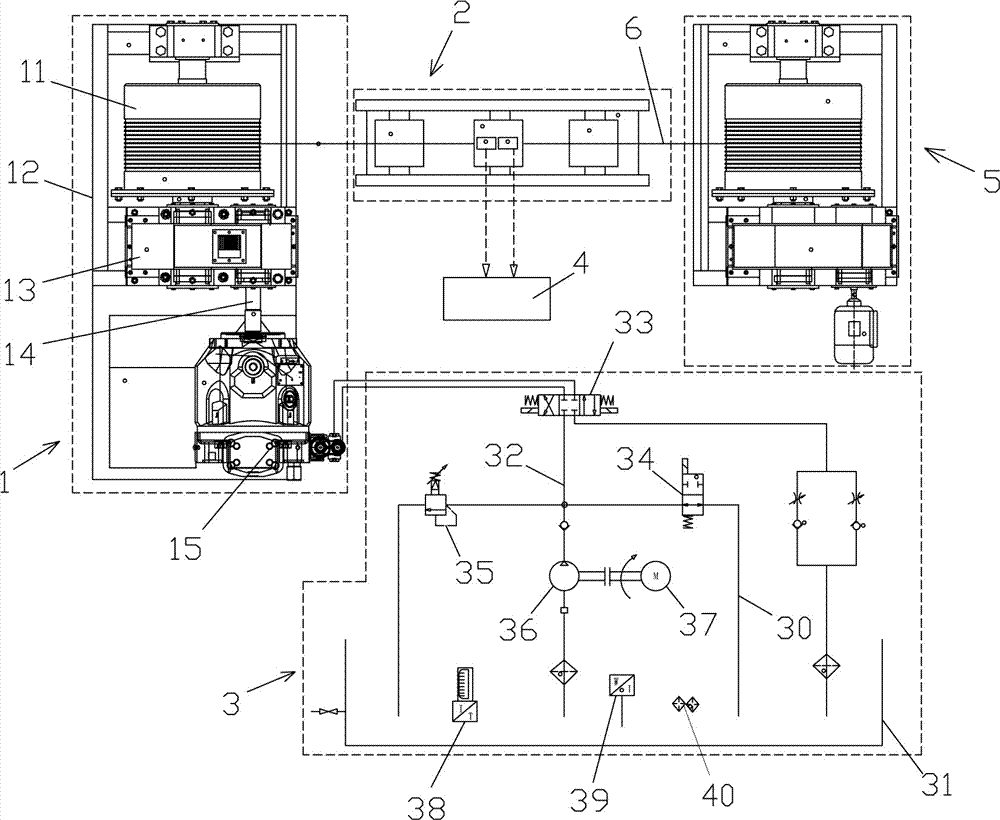

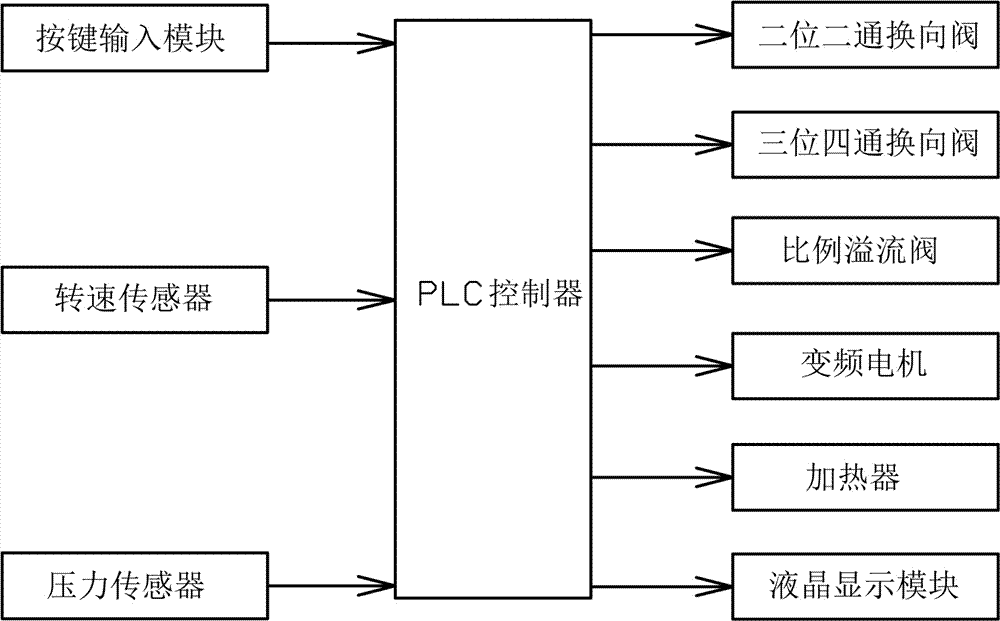

[0023] Such as figure 1 and 2 As shown, a marine marine winch load simulation experiment device includes a load winch 1, a test device 2, a hydraulic system 3 and a control system 4;

[0024] The load winch 1 includes a base 12 and a two-way hydraulic motor 15 installed on the base 12, a test reel 11 and a reducer 13. The hydraulic motor 15 is connected to the input end of the reducer 13 through a universal joint 14, and the output end of the reducer 13 is connected through a coupling Connected with the test reel 11, the hydraulic motor 15 is connected with the hydraulic system 3, the cable 6 is wound on the test reel 11, and one end of the cable 6 passes through the test device 2 and is connected with the winch 5 to be tested;

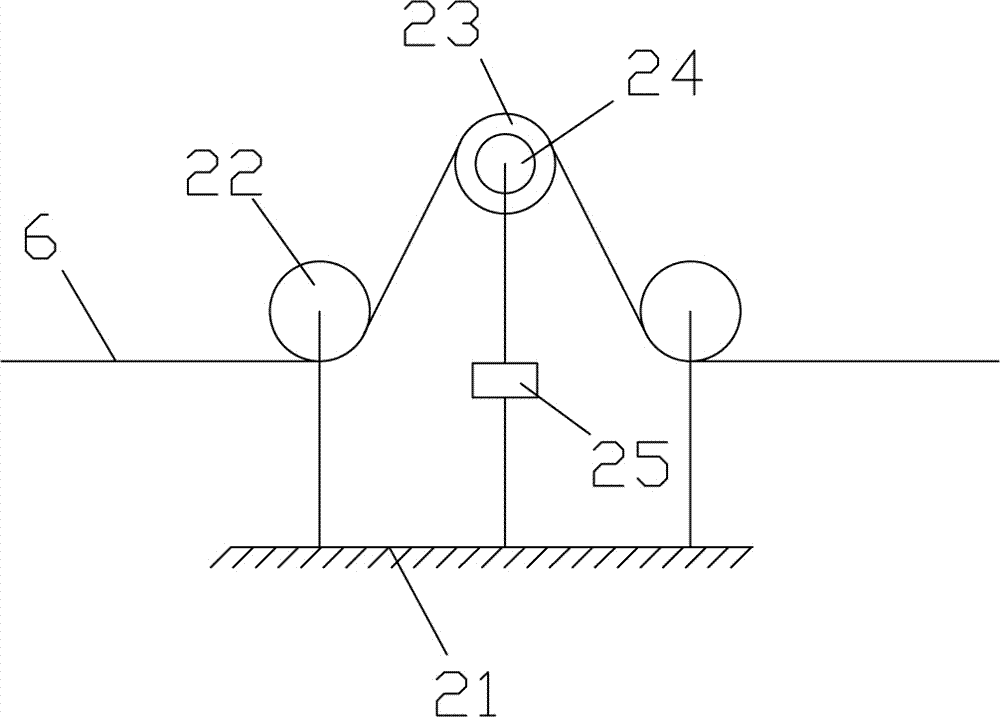

[0025] The testing device 2 comprises a support frame 21, on which a higher first pulley 23 and two shorter second pulleys 22 are installed, and the two second pulleys 22 are respectively arranged on both sides of the first pulley 23, A pressure sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com