Batch drilling well wellhead design and assembling-disassembling method for modular drilling machine

A drilling rig and drilling technology, which is applied in the field of wellhead design and disassembly and assembly of modular drilling rigs in batches, can solve the problems of time and labor in disassembly and assembly of wellheads, and achieves a high-efficiency and safe operation and a simple structure with reduced labor costs and equipment costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further explained below in conjunction with specific embodiments.

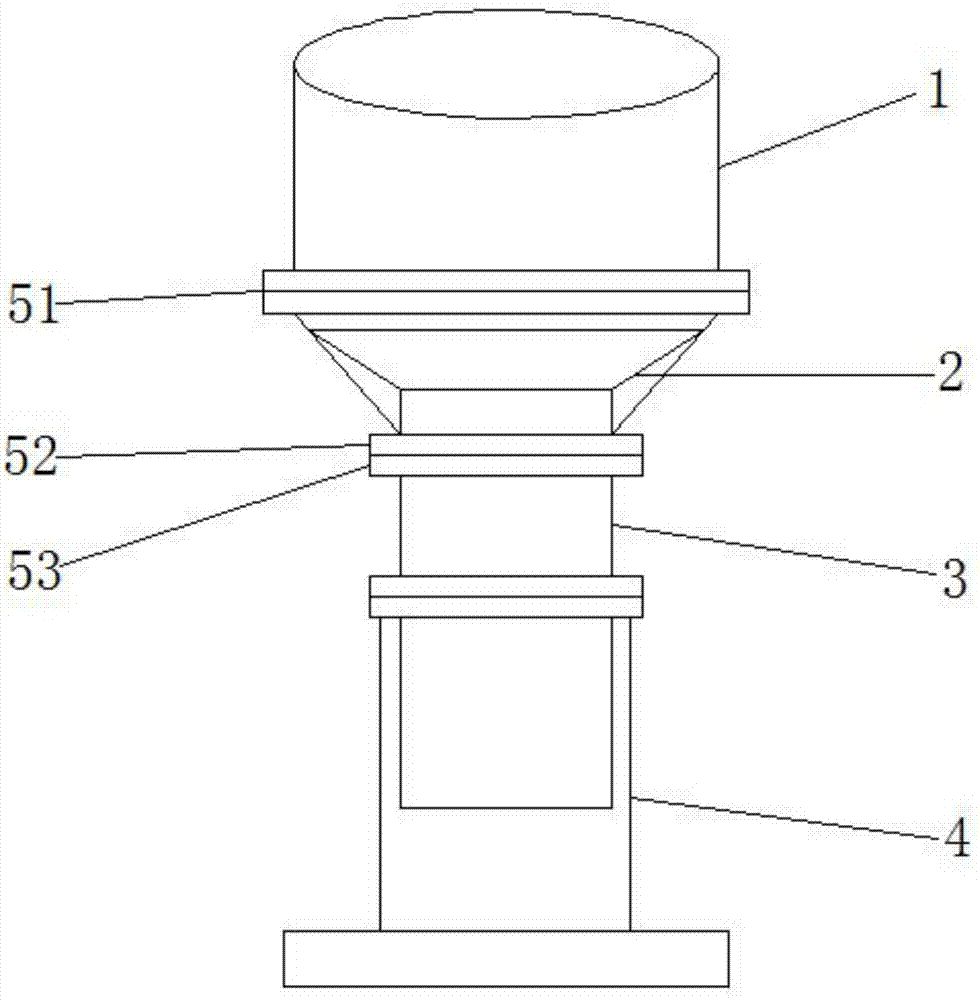

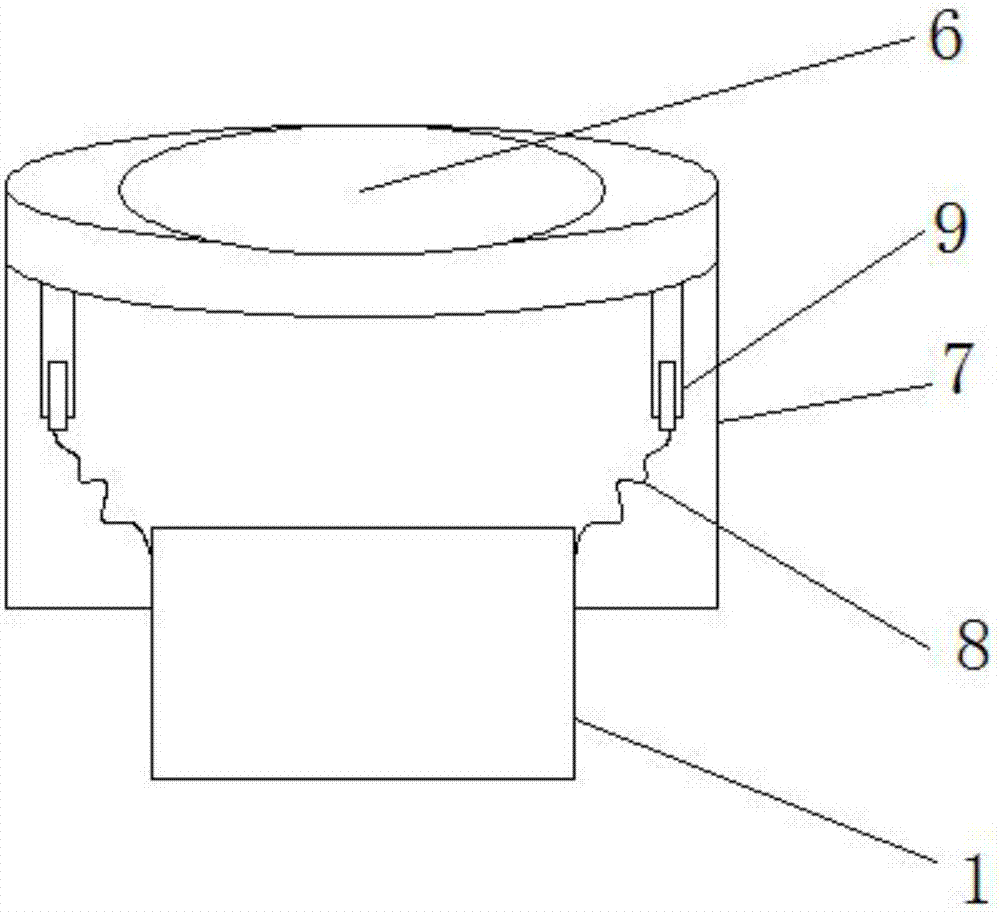

[0057] Reference figure 1 -, a modular drilling rig batch drilling wellhead design proposed in the present invention, including the design of the following supporting facilities: wellhead deck design that is sufficiently convenient to operate, split bell mouth design, bell mouth fixing method design, bell mouth and return pipe and metering Pump grouting pipeline fixed design, bell mouth reducing diameter design, special tool design for bell mouth reducing diameter hoisting, retractable inner and outer barrel horn design, special pressure plate seal or inflatable pneumatic tire union seal design, special rising pipe Suspension rope design, special riser length design, special riser suspension channel design;

[0058] The wellhead deck design that is sufficiently convenient to operate is to compress the operating aisle outside the lower part of the turntable for disassembling the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com