Treatment method and treatment system of wastewater of sweet potato vermicelli

A waste water treatment system, technology of sweet potato vermicelli, applied in food industry waste water treatment, water/sewage treatment, biological water/sewage treatment, etc., can solve the problems of reducing protein nutritional value, protein corruption, air pollution, etc., to reduce production costs , reduce waste water discharge, reduce the effect of pollution load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

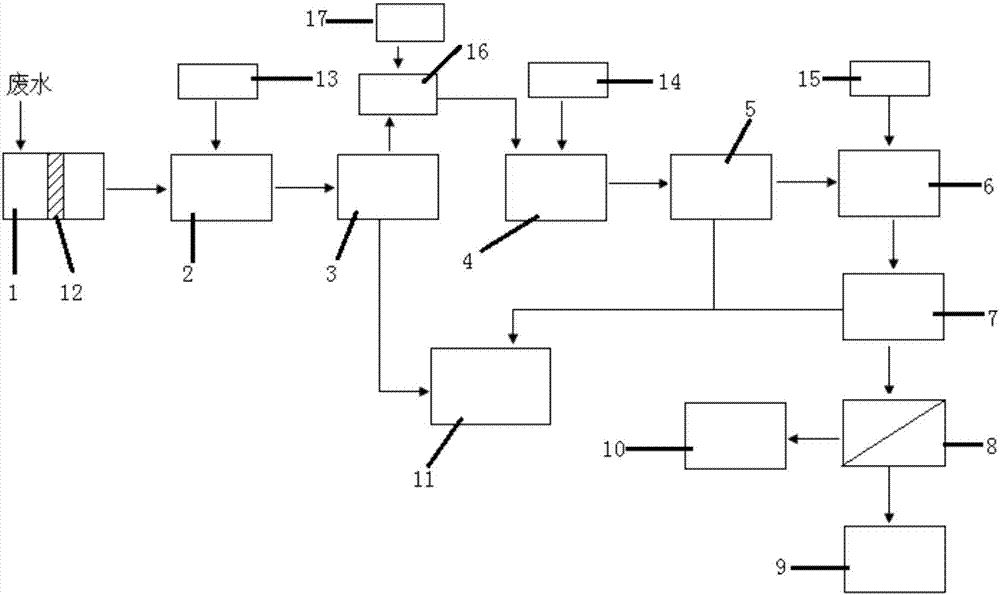

[0054] Such as figure 1 As shown, a wastewater treatment system for sweet potato vermicelli, comprising a pretreatment tank 1, a flocculation tank 2, a first centrifuge 3, an enzymolysis tank 4, a second centrifuge 5, a separation tank 6, a third centrifuge connected in sequence through pipelines Centrifuge 7, reverse osmosis treatment device 8 and reuse pool 9;

[0055] The entrance of described pretreatment pond 1 is connected with sweet potato vermicelli waste water outlet; The middle part of described pretreatment pond 1 is provided with strainer 12, and the bottom side of described pretreatment pond 1 middle part is provided with sundry outlet; The pretreatment The side of pool 1 is provided with the outlet of pretreatment pool, and the outlet of described pretreatment pool is connected with the entrance of flocculation pool 2;

[0056] The inlet of the flocculation tank 2 is also connected to the outlet of the flocculant dosing device 13; when the flocculant is added to...

Embodiment 2

[0068] The difference with embodiment 1 is that a kind of wastewater treatment method of sweet potato vermicelli, concrete steps are as follows:

[0069] 1) Collect the wastewater discharged during the production of sweet potato vermicelli, filter the wastewater through a 50-mesh filter, add organic polymer flocculant polyacrylamide aqueous solution and inorganic flocculant polyaluminum chloride aqueous solution to the filtrate, and mix well to form a stable Flocculation, the macromolecular insoluble substances in the wastewater are separated, and the insoluble substances are removed by centrifugation in a horizontal screw discharge sedimentation centrifuge; the insoluble substances are dried to obtain feed; the addition of the polyacrylamide aqueous solution accounts for 4% of the volume of the wastewater , the mass percent concentration is 0.1%, the addition of polyaluminum chloride aqueous solution is 2% of the waste water volume, and the mass percent concentration is 5%; th...

Embodiment 3

[0074] The difference with embodiment 1 is that a kind of wastewater treatment method of sweet potato vermicelli, concrete steps are as follows:

[0075] 1) Collect the wastewater discharged during the production of sweet potato vermicelli, filter the wastewater through a 200-mesh filter, add organic polymer flocculant polyacrylamide aqueous solution and inorganic flocculant polyaluminum chloride aqueous solution to the filtrate, and mix well to form a stable Flocculation, the macromolecular insoluble substances in the wastewater are separated, and the insoluble substances are removed by centrifugation in a horizontal screw discharge sedimentation centrifuge; the insoluble substances are dried to obtain feed; the addition of the polyacrylamide aqueous solution accounts for 4% of the volume of the wastewater , the mass percent concentration is 0.1%, the addition of polyaluminum chloride aqueous solution is 1% of the waste water volume, and the mass percent concentration is 10%; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com