Well lid installing machine

A technology for installing machines and manhole covers, which is applied in hoisting devices, hoisting devices, etc., which can solve the problems of inconvenient operation and high installation costs, and achieve the effects of simple use procedures, improved construction efficiency, and guaranteed project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

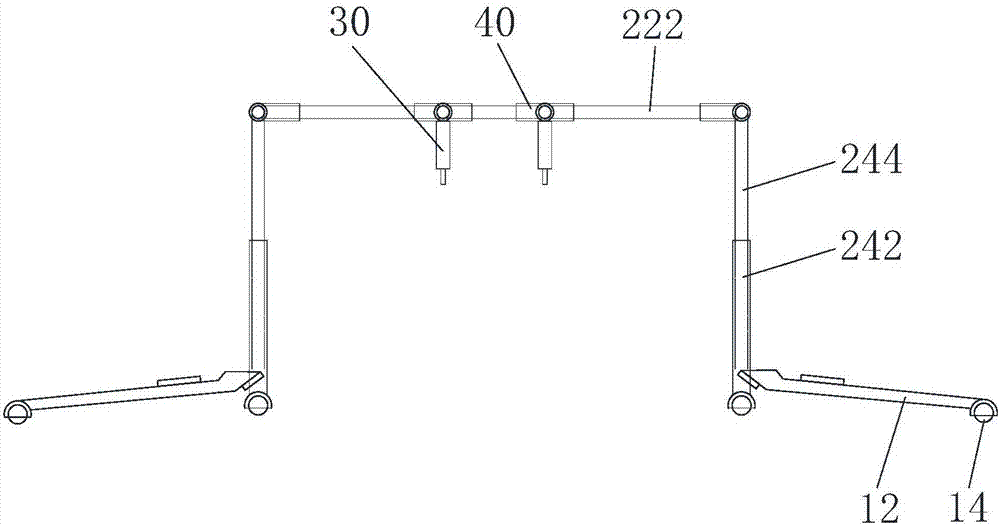

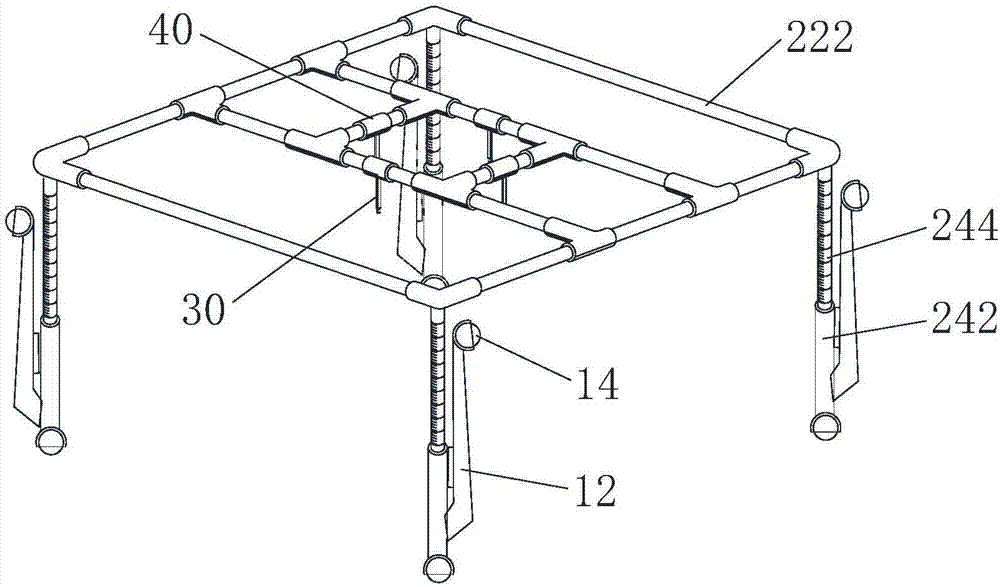

[0033] see figure 1 , figure 2 and image 3 As shown, the present invention proposes a well cover installation machine, which includes a hoisting mechanism and a lifting mechanism. The hoisting mechanism includes a base 10 that can move freely on the ground outside, a frame fixed on the base 10, and at least three suspenders 30; the upper ends of each suspender 30 are respectively connected to the frame, and the lower ends are detachably connected to the frame to be installed. manhole cover. The lifting mechanism drives the suspenders 30 to move up and down synchronously, so that the suspenders 30 drive the manhole cover to move up and down.

[0034] The manhole cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com