Efficient multistage crushing solid waste treating device

A solid waste and processing device technology, applied in grain processing, drying solid materials, heating to dry solid materials, etc., can solve problems such as low processing particle size requirements and poor crushing efficiency, and achieve energy saving, cost saving, and improving The effect of crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

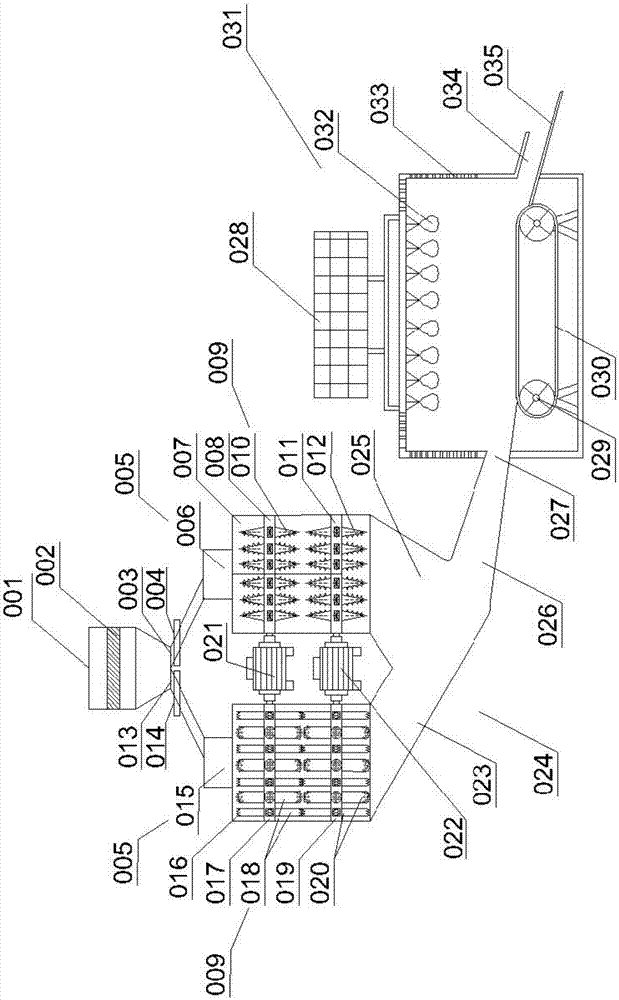

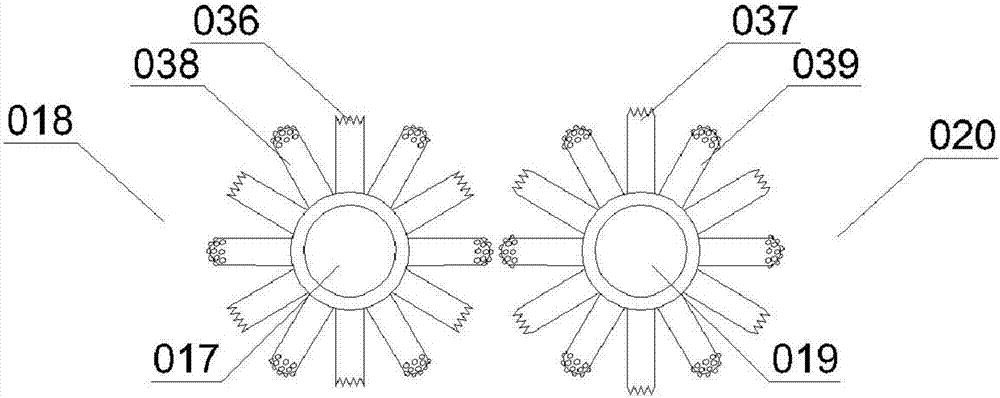

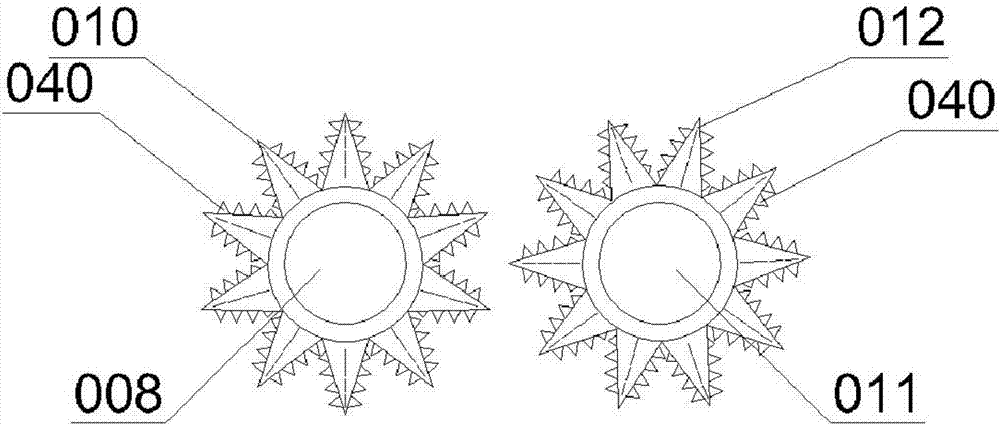

[0028] Such as Figure 1-3 As shown, this embodiment provides a high-efficiency multi-stage crushing solid waste treatment device, including a feeding mechanism 001, a stirring mechanism 005, a crushing mechanism 009, a transportation pipeline 024, and a drying mechanism 031 connected in series. A layer of screen 002 is set, and the bottom of the feeding mechanism 001 is provided with a discharge port A 013 and a discharge port B 003, and the discharge port A 013 is connected in series with the stirring device A 015 and the crushing mechanism A 016 in sequence. Port B 003 connects agitating device B006 and crushing mechanism B 007 in series in sequence. Between said crushing mechanism A 016 and crushing mechanism B 007, a double-shaft motor I021 and a double-shaft motor II022 that provide power for the crushing mechanism 009 are arranged. The crushing mechanism A 016 and the bottom of the crushing mechanism B 007 are connected with the drying mechanism 031 through the transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com