Skin care gel and preparation method thereof

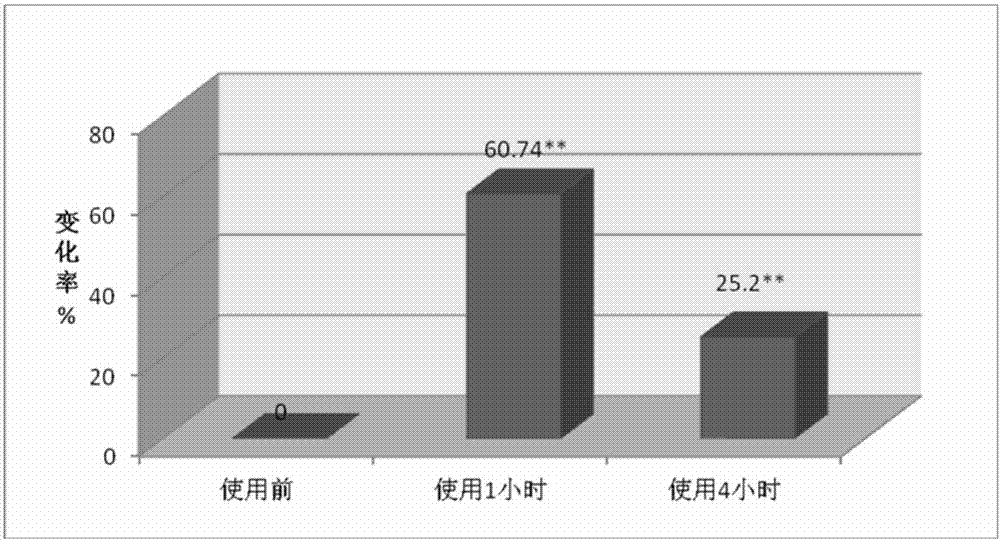

A technology of skin care gel and xanthan gum, applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve problems such as no improvement of skin problems and change of dry skin, so as to improve the oxygen consumption rate of cells and promote The effect of secretion and increase of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The components and percentages thereof that form the skin care gel are:

[0060]

[0061] The preparation method of the above-mentioned skin care gel comprises the following steps: adding water, glycerin, allantoin, disodium EDTA and sodium hyaluronate into the water phase pot, starting to stir, heating to 75-80°C, and dispersing evenly, as A phase; add caprylic / capric triglyceride, dimethicone, xanthan gum, dioctyl carbonate, and hydroxyethyl acrylate / sodium acryloyldimethyl taurate copolymer to the oil phase pot, Heat to 75~80°C, stir and disperse evenly, and use it as phase B; pump phase A and phase B into a homogeneous reaction pot, homogenize at high speed for 5 minutes, turn on cooling circulating water, stir and cool down, and wait until the temperature drops to 40~45 At ℃, add pearl extract, yeast lysate extract, guava fruit extract, essence and preservative into the reaction pot, homogenize for 1 minute; continue to stir and cool until the temperature of the...

Embodiment 2

[0063] The components and percentages thereof that form the skin care gel are:

[0064]

[0065] The preparation method of the above skin care gel comprises the following steps: adding water, glycerin, butylene glycol, betaine and sodium hyaluronate into the water phase pot, starting to stir, heating to 75-80°C, and dispersing evenly, as Phase A ; Add caprylic / capric triglyceride, polydimethylsiloxane, xanthan gum, dioctyl carbonate and ammonium acryloyldimethyl taurate / VP copolymer into the oil phase pot, heat to 75~ 80°C, stir and disperse evenly, as phase B; pump phase A and phase B into a homogeneous reaction pot, homogenize at high speed for 5 minutes, turn on cooling circulating water, stir to cool down, when the temperature drops to 40~45°C, add Add pearl extract, yeast lysate extract, guava fruit extract, essence and preservative into the reaction pot, homogenize for 1 minute; continue to stir and cool until the temperature of the material is lower than 38°C, stop s...

Embodiment 3

[0067]

[0068] The preparation method of the above-mentioned skin care gel comprises the following steps: adding water, 1,3-propylene glycol, tetrasodium EDTA, allantoin and sodium hyaluronate into the water phase pot, starting stirring, heating to 75-80°C, and dispersing Uniform, as Phase A; triglyceride, cyclopentasiloxane, dioctyl carbonate, and ammonium acryloyldimethyltaurate / beheneth-25 Add the base acrylate crosslinked polymer into the oil phase pot, heat to 75~80°C, stir and disperse evenly, and use it as phase B; pump phase A and phase B into the homogenization reaction pot, homogenize at high speed for 5 minutes, turn on cooling Circulate water, stir to cool down, when the temperature drops to 40~45°C, add pearl extract, yeast lysate extract, guava fruit extract, essence and preservative into the reaction pot, homogenize for 1 minute; continue Stir and cool until the material temperature is lower than 38°C, stop stirring, and end.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com