High-temperature forged part surface defect in-position detecting method based on PCA and CNN

A detection method and technology for forgings, applied in computer parts, character and pattern recognition, image data processing, etc., can solve the problems of scrapped forgings, improved machining accuracy, easy damage to molds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

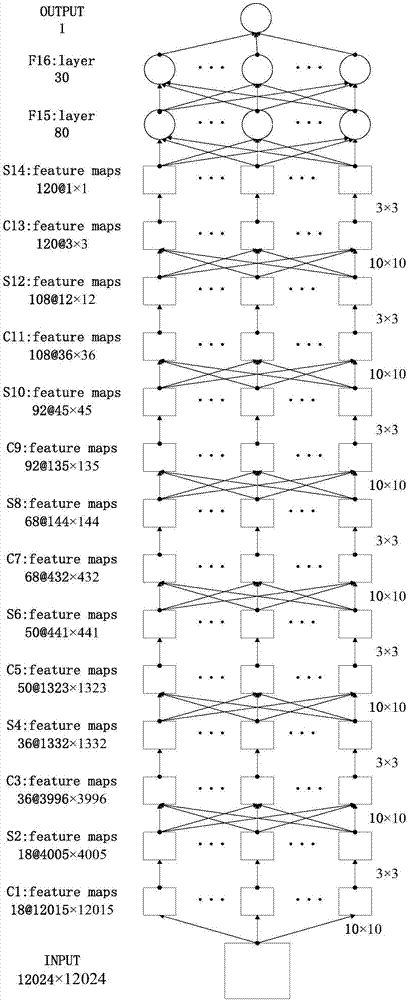

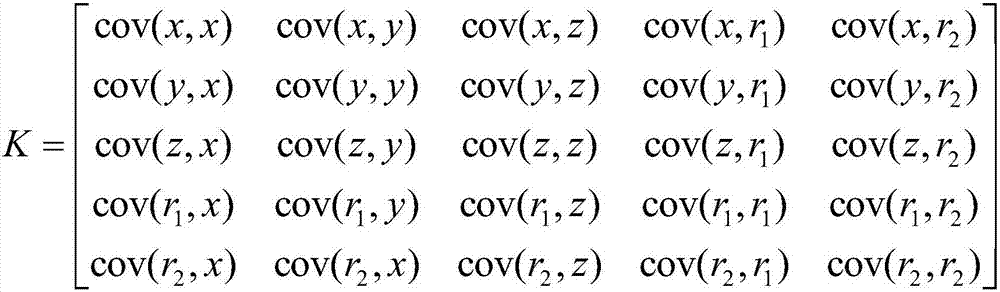

[0102] S10: At a distance of about 12 meters from the standard forging without surface defects, a standard forging 3D point cloud data set containing 12,024 point clouds is acquired through a blue-ray 3D laser scanner, and the point cloud of each standard forging is fitted according to the ellipsoidal surface Calculate its two principal curvatures, select the three-dimensional coordinate value of each standard forging point cloud and its two principal curvatures as the five features representing the standard forging point cloud, so as to obtain the standard forging five-dimensional point cloud data set.

[0103] S20: Use the PCA method of principal component analysis to reduce the dimensionality of the standard forging five-dimensional point cloud data set to two-dimensional, thereby obtaining the standard forging two-dimensional point cloud data set, and use the standard forging two-dimensional point cloud data set to represent the corresponding The standard forging without su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com