Color film substrate, liquid crystal display panel, and liquid crystal display

A technology for liquid crystal display panels and color filter substrates, which is used in instruments, nonlinear optics, optics, etc., and can solve the problems of flexible panel color resistance breakage, broken display screen, and large color resistance area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

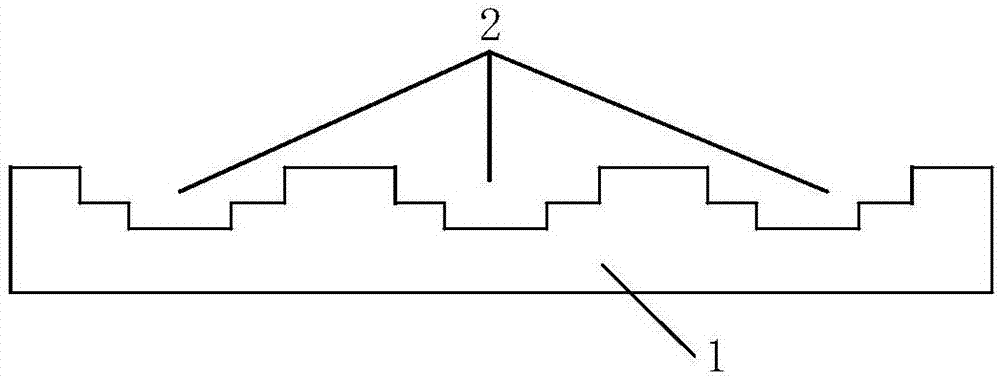

[0059] Preferred Implementation Mode 1: Please refer to Figure 5 , in a rhombus, the angle at the apex of the depression 2 in the middle depression 2 column is 120°.

[0060] That is to say, in the rhombus structure above, the line connecting the distances between the four depressions 2 can form two equilateral triangles, and in each equilateral triangle, the lengths of the distances connecting the three depressions 2 are equal. It should be noted that the triangular structure makes the stresses on the stepped structures of the respective recesses 2 equal to each other, so as to enhance the effect of relieving stress.

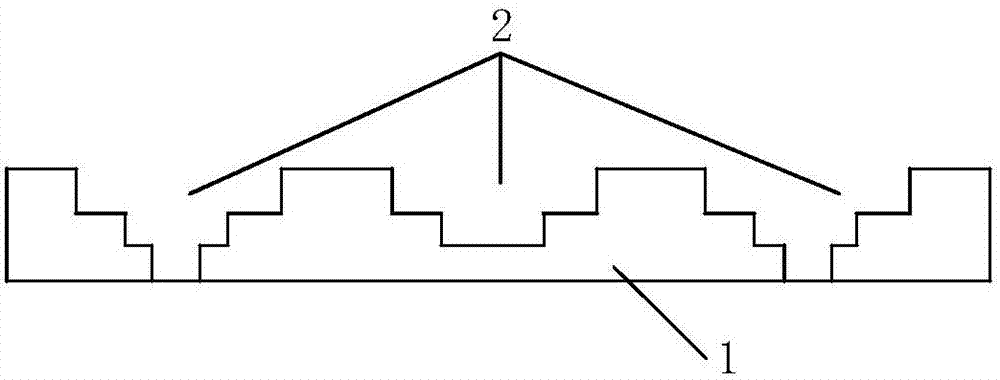

[0061] Preferred Implementation Mode 2: Please refer to Image 6 , in a rhombus, the ratio of the distance between every two adjacent depressions 2 in the middle column of depressions 2 to the distance between the other two depressions 2 is the same as the aspect ratio of the display area of the color filter layer 1 .

[0062] It should be noted that, in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com