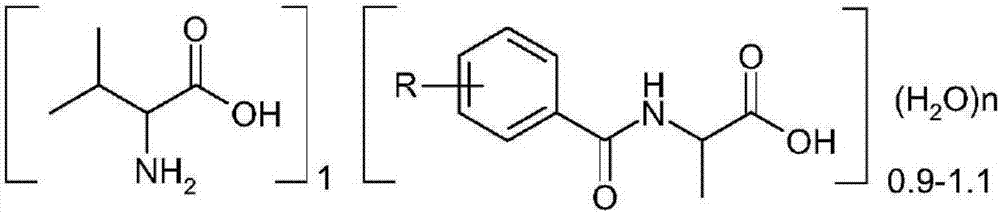

Method for purifying L-valine from L-valine complex

A valine and compound technology, applied in the field of purifying L-valine, can solve the problems of many impurities affecting the purity and quality of finished products, and achieve the effects of high purification yield, low cost and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1000ml reaction bottle, add 100g of L-valine complex, add 300g of methanol, stir and heat up to reflux for 60min, filter while hot, return the solid to the kettle, continue to add 300g of methanol, stir and heat up to reflux for 60min, filter while hot, repeat this three times , dried to obtain 33g of L-valine crude product, dissolved the solid in 350ml of water, added 0.3g of activated carbon, boiled and decolorized for 45min, filtered while hot, concentrated the filtrate to 100ml under reduced pressure, and L-valine solid precipitated, cooled to 25 °C filtration to obtain 25 g of L-valine.

Embodiment 2

[0027] 1000ml reaction bottle, add 100g of L-valine complex, add 250g of ethanol, stir and raise the temperature to reflux for 60min, filter while hot, return the solid to the kettle, continue to add 250g methanol, stir and raise the temperature to reflux for 60min, filter while hot, repeat this three times , and dried to obtain 35.5 g of L-valine crude product. Dissolve the solid in 400ml of water, add 0.4g of activated carbon, boil for 30min to decolorize, filter while hot, concentrate the filtrate to 100ml under reduced pressure, L-valine solid precipitates, cool to 30°C and filter to obtain 30g of L-valine.

Embodiment 3

[0029] 1000ml reaction bottle, add 150g of L-valine complex, add 440g of methanol, stir and raise the temperature to reflux for 2h, filter while hot, return the solid to the kettle, continue to add 440g of methanol, stir and raise the temperature to reflux for 2h, filter while hot, repeat this three times , and dried to obtain 52 g of L-valine crude product. Dissolve the solid in 600ml of water, add 0.50g of activated carbon, boil for 45min to decolorize, filter while hot, concentrate the filtrate to 100ml under reduced pressure, L-valine solid precipitates, cool to 25°C and filter to obtain 42g of L-valine.

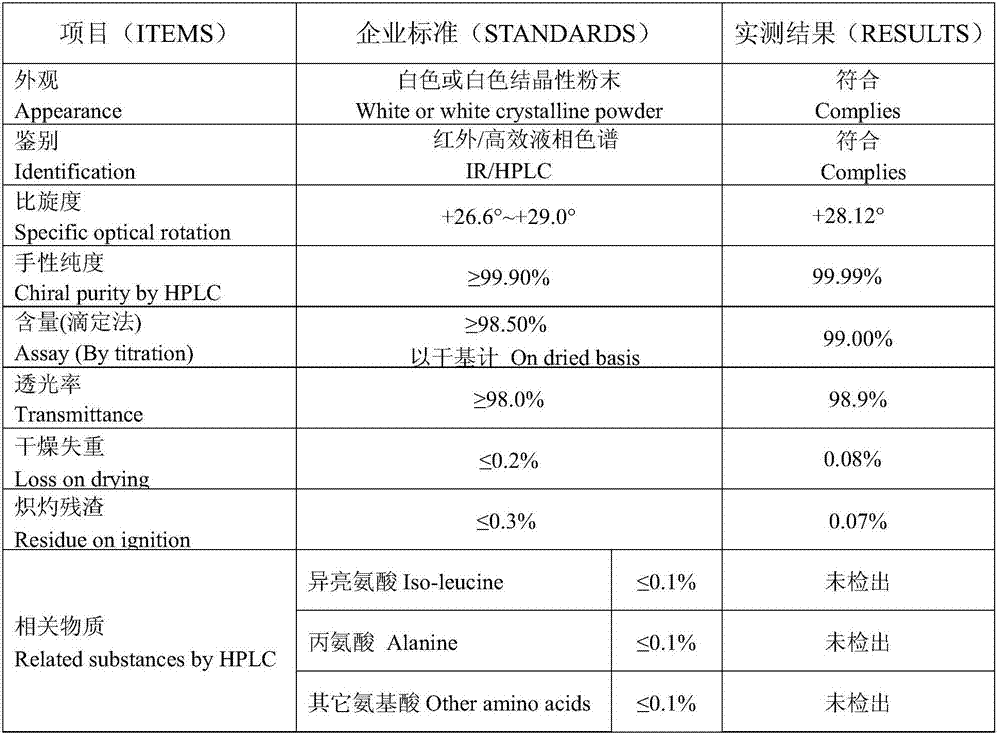

[0030] Evidence of the positive (beneficial) effects that can be produced by applying the present invention

[0031] Table 1 embodiment 1 product quality standard and technical index

[0032]

[0033] Table 2 embodiment 2 product quality standards and technical indicators

[0034]

[0035]

[0036] Table 3 embodiment 3 product quality standards and technical i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com