A kind of connection method of silicon carbide ceramic material

A technology of silicon carbide ceramics and connection methods, which is applied in the field of silicon carbide ceramic materials, can solve problems such as affecting the connection strength of components and easily forming brittle compounds, and achieve the effects of increasing interface surface energy, strengthening connections, and reducing production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but have no limiting effect on it.

[0026] In this embodiment, the material to be connected is silicon carbide ceramics, and the connection method is as follows:

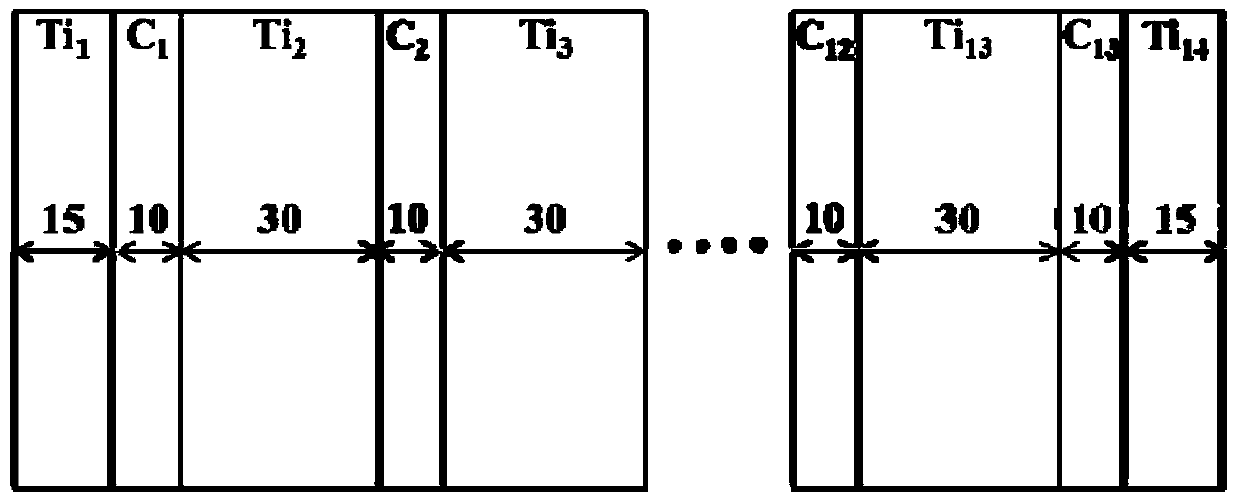

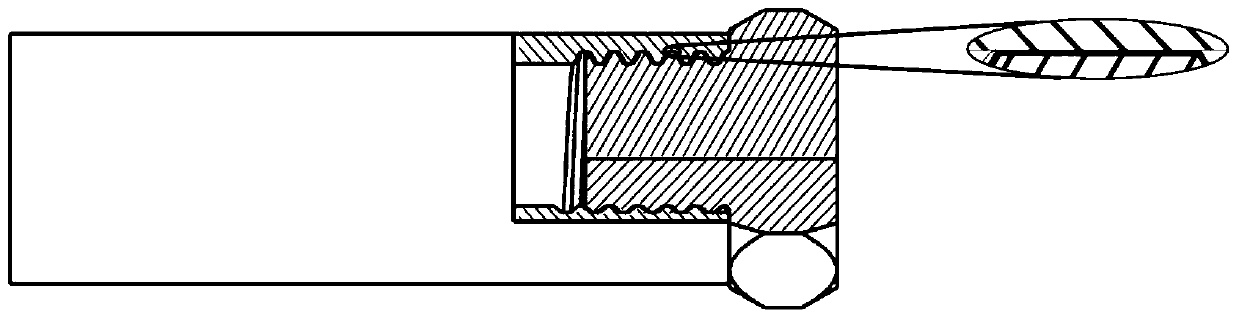

[0027] The connecting layer material is as figure 1 and image 3 Nuts and bolts shown, connection method is electric field assisted connection.

[0028] The specific implementation steps are as follows:

[0029] (1) Roughly polish the surface of silicon carbide ceramics with a diameter of 20 mm and a height of 20 mm with a 0.1 micron diamond polishing solution to remove larger defects and impurities on the surface;

[0030] (2) Machine a concave M8 countersunk threaded hole at the position to be connected of a piece of silicon carbide ceramic; process the posit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com