Aligning bending welding integrated device

A technology of straightening and welding machines, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as poor stability of skeleton steel rings and steel wire spokes, affect the consistency of welding quality, and occupy a large space for equipment, and achieve lap joints Uniformity, reduce labor costs and space occupancy, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

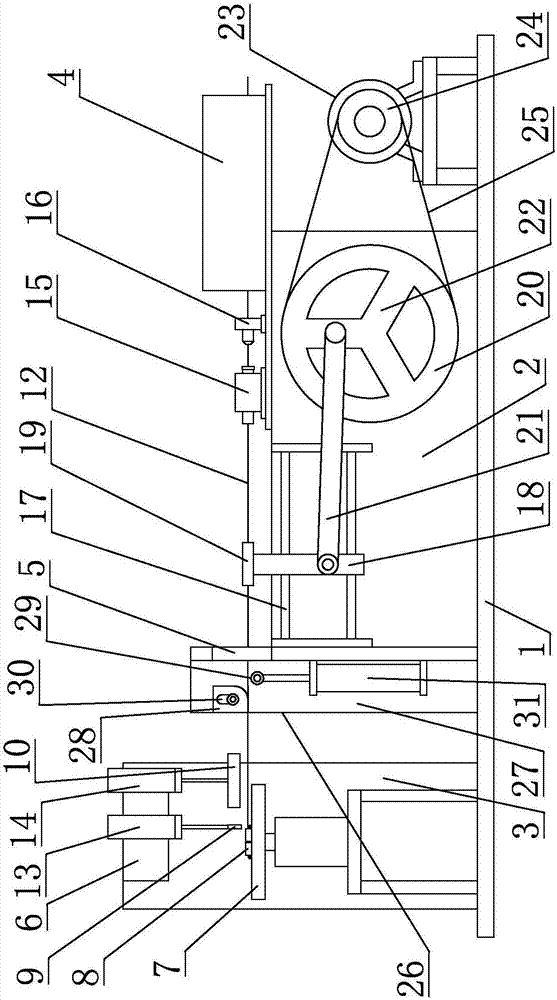

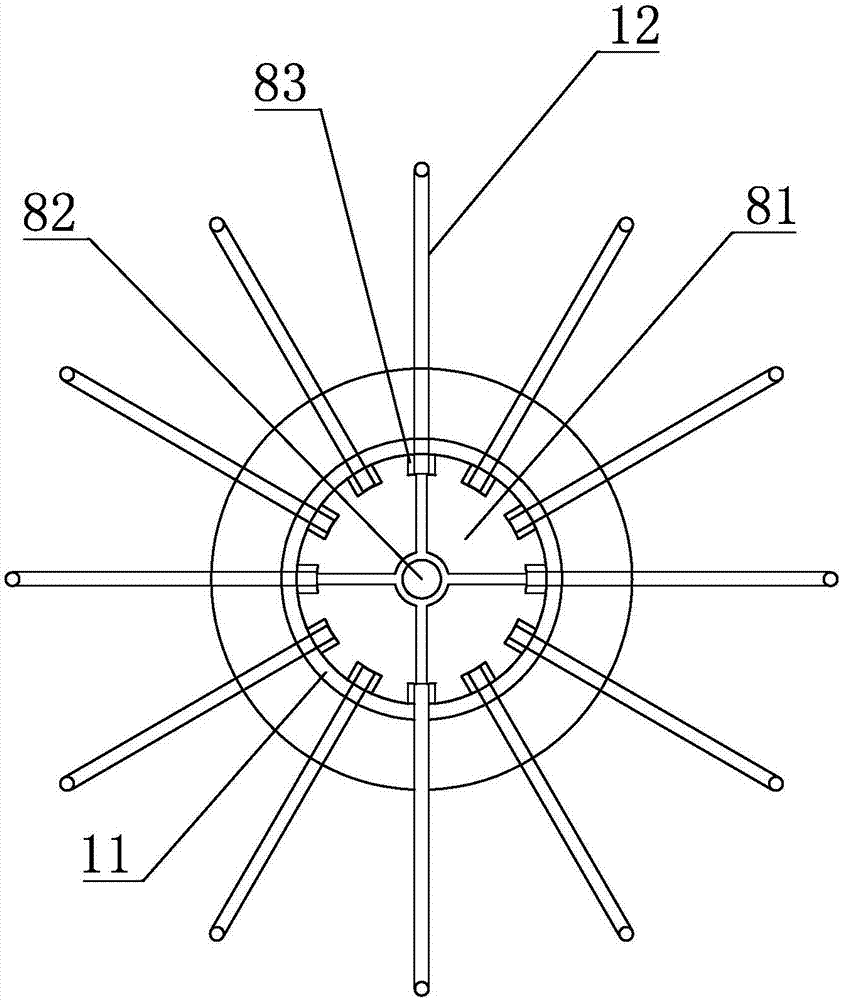

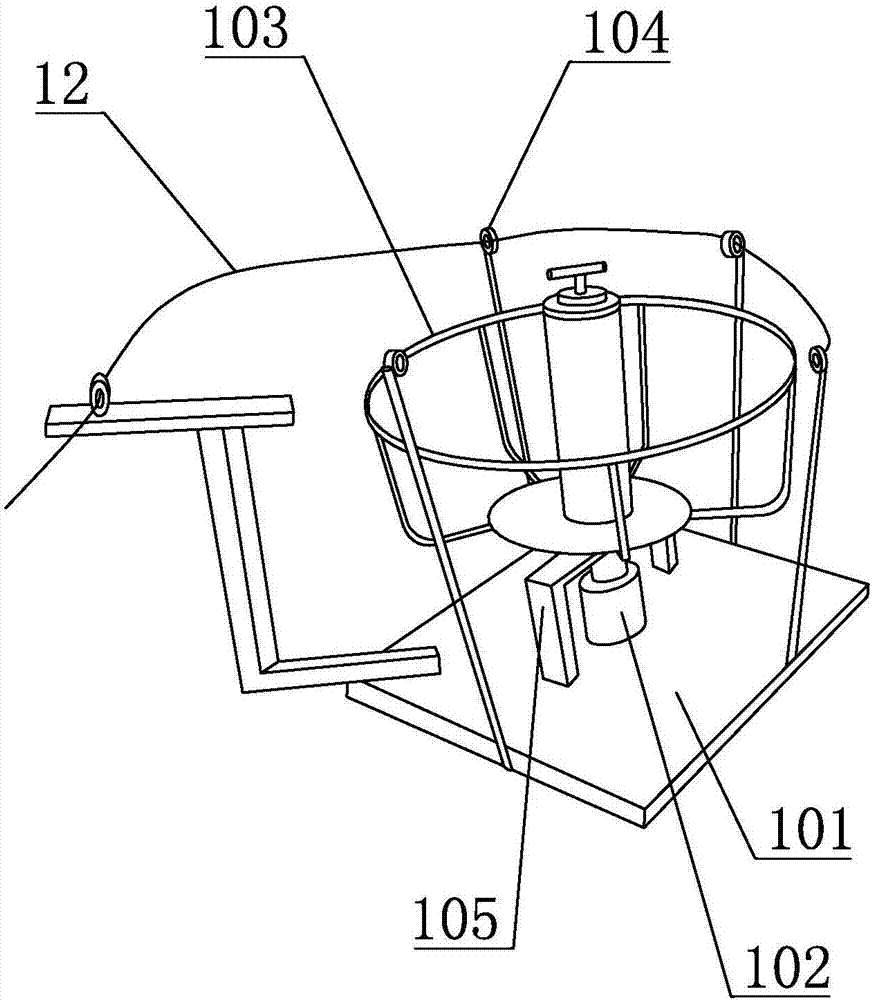

[0017] refer to Figure 1 to Figure 3 , an integrated device for straightening, punching and bending welding, including a wire release device, a base 1, a welding machine and a control system, an intermediate frame 2 and a frame 3 are fixed on the base 1, and the top end of the intermediate frame 2 is provided with a straightening device 4, the other end is provided with a cutting device 5; the top of the frame 3 is provided with a forward cantilever 6, the bottom of the cantilever 6 is provided with a copper drive disc 7 that can rotate counterclockwise with equal clearance, and the middle part of the drive disc 7 is provided with a The steel ring positioning device 8 that shrinks and expands outwards, the cantilever 6 is provided with a welding block 9 and a pressing block 10 that can be controlled by the control system to move up and down, the welding block 9 is facing the steel ring 11 positioned on the steel ring positioning device 8 and It is connected with the positive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com