High-efficient dust removal device

A dust-removing device and high-efficiency technology, which can be used in dry gas layout, photovoltaic modules, filter circuits, etc., can solve the problem that the cleaning mechanism does not have the function of water spray, and achieve the advantages of enhancing the comprehensive mechanical properties of machinery, saving water resources, and improving cleaning efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

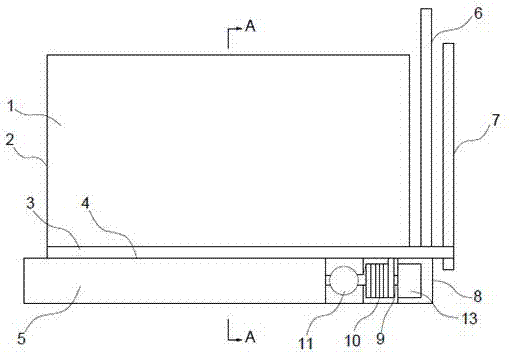

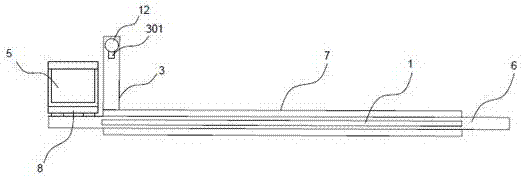

[0019] like Figure 1~3 As shown, a high-efficiency dust removal device includes a photovoltaic panel 1, a nozzle bracket 3 connected to the photovoltaic panel 1 by the first edge 4, a water pipe 12 is arranged on the nozzle bracket, and evenly distributed nozzles 301 are arranged below the water pipe 12. The nozzle bracket 3. There is a water collection tank 5 connected to the rear. The water collection tank 5 includes a tank body and a cover. The cover body is pivotally connected to the tank body, and the cover body is also connected to the second motor. 5 One end is connected to a water pump 11, the water pump 11 is connected to the rotating shaft 9 through the hose 10, the rotating shaft 9 is connected to the first motor 13, the sump 5 and the water pump 11 are respectively connected to the bracket 8, and the photovoltaic panel 1 is on the side of the second edge 2 A first slide rail 7 is provided, and the first slide rail 7 is slidingly connected with the nozzle bracket 3...

Embodiment 2

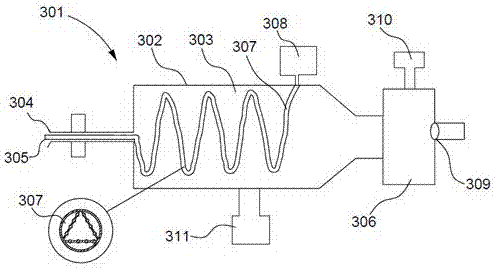

[0023] like Figure 1-3 As shown, a simple photovoltaic panel cleaning device of the present invention is suitable for installation on the photovoltaic panel 1 under strong sunlight. On the tank body, rainwater can be retained for as long as possible. In sunny or cloudy days, the cover body is closed on the tank body. In rainy or snowy days, the cover body is opened, and the tank body collects rainwater. When it is necessary to clean the photovoltaic panel 1 At this time, the water pump 11 can draw water from the water collection tank 5, and deliver it to the water pipe 12 on the nozzle bracket 3 through the hose 10, and then spray it out from the nozzle 301. When the nozzle 301 is in use, the water inlet is connected to the water supply pipe, and the water flows out The water outlet is sprayed out, and the water outlet and the cavity 303 are integrated. In order to adjust the direction of water spray, an adjustment bracket 311 is provided under the housing 302 to adjust the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com