Multi-chip white LED package structure

A LED packaging, multi-chip technology, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problems of incomplete light mixing, chips cannot be overlapped, mixed into white light, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0020] The structural implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings.

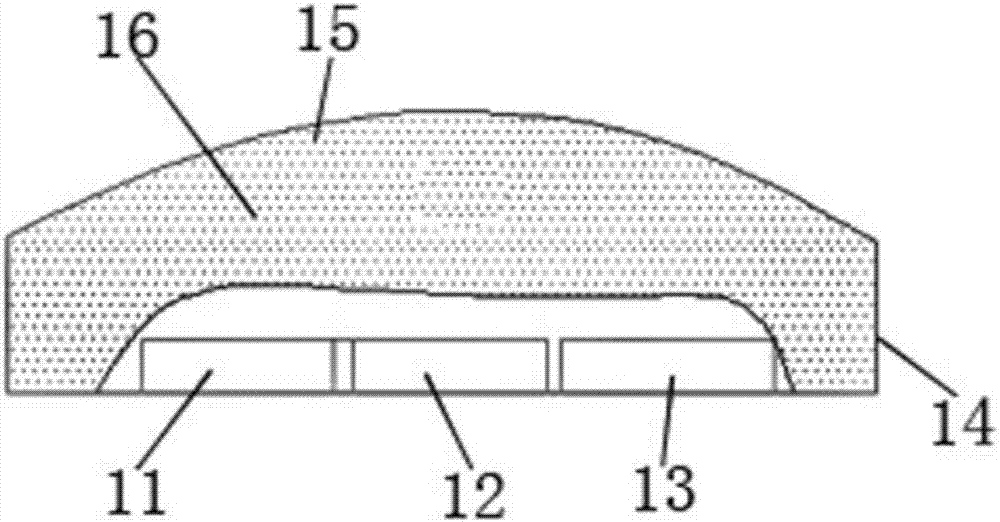

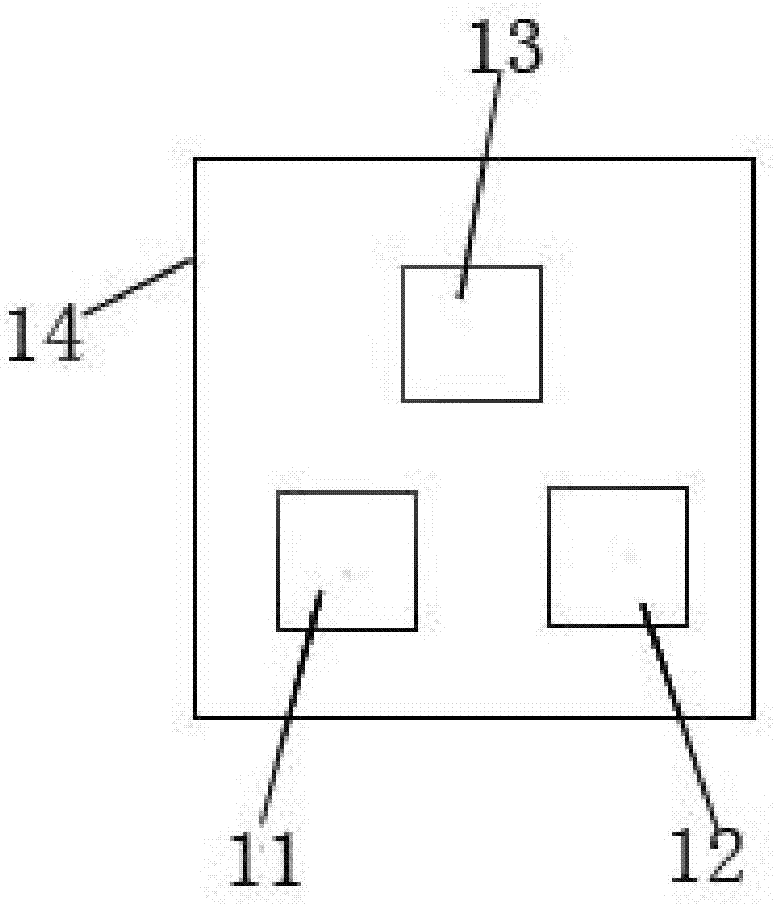

[0021] Such as figure 1 - figure 2 A first embodiment of the present invention is shown. A multi-chip white light LED packaging structure. It includes a bracket 14, a first light-emitting chip 12 installed in the bracket 14, a second light-emitting chip 11, a third light-emitting chip 13, a plurality of pads, and an encapsulant 15 for packaging each light-emitting chip in the bracket 14. The encapsulation glue 15 is preferably epoxy resin, the first light-emitting chip 12 is arranged on a pad, the second light-emitting chip 11 and the third light-emitting chip 13 are connected in parallel or in series and are arranged on their respective pads, the above three kinds of light-emitting chips are respectively Electrically connected to the respective pads, the encapsulation glue 15 encapsulates the three kinds of light-emitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com