Method for increasing gear hob processing accuracy

A technology of machining accuracy and gear hobbing, applied in the fields of genetic laws, instruments, electrical and digital data processing, etc., it can solve problems such as inability to comprehensively model multiple indicators, inability to predict tooth surface profile errors, machine tool damage, etc., and achieve fast solution speed. , The effect of optimizing the effect to improve and reduce the modeling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Taking the 40Cr processed gear as an example, YGS3110B CNC gear hobbing machine is used. The basic parameters of the gear are: modulus m n=2, number of teeth z=6, gear helix angle β=30°, pressure angle α=20°. The basic parameters of the hob are: modulus m n =2, number of heads z=1, hob helix angle β=4.25°, pressure angle α=20°. Use the JD45 gear measuring center to detect the tooth profile errors.

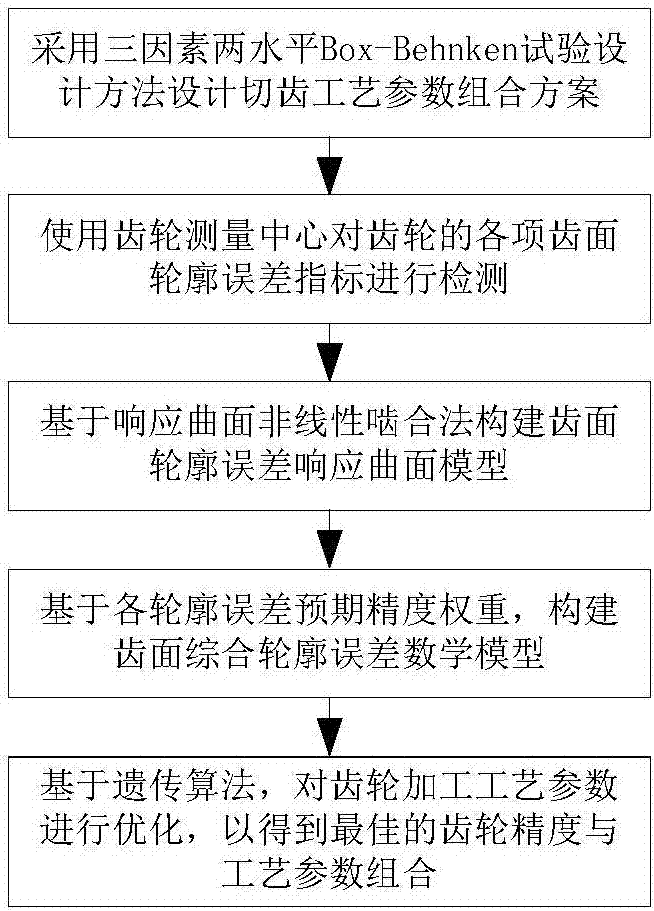

[0041] see figure 1 , an operation step to improve hobbing precision is as follows:

[0042] Step (1), according to the hobbing process of the processed gear, extract the hobbing process parameters that affect the gear machining accuracy, design the combination of hobbing process parameters, conduct hobbing processing experiments, and obtain the tooth surface profile error index of the processed gear.

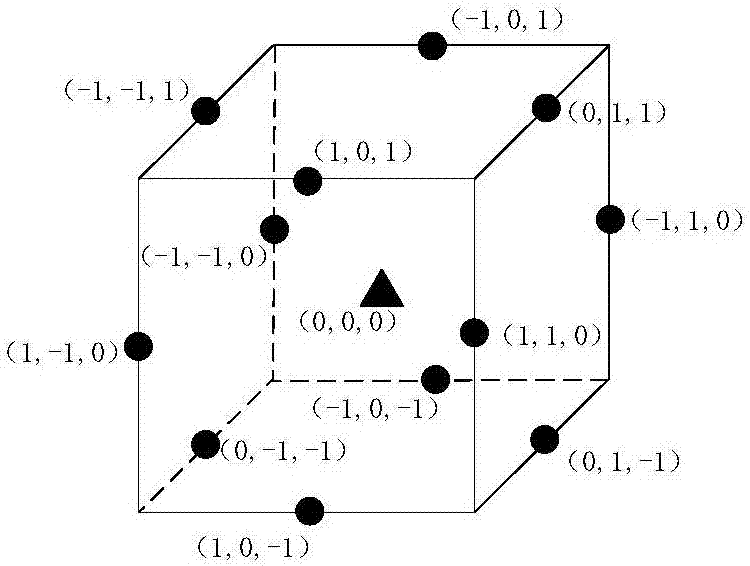

[0043] The present invention is mainly aimed at gear hobbing processing, and the three gear hobbing process factors are hob speed S S , rolling cutting depth h d , Axi...

Embodiment 2

[0073] 1. Workpiece parameters

[0074] Concrete flow process of the present invention is as figure 1 shown. Taking the 40Cr processed gear as an example, YGS3110B CNC gear hobbing machine is used. The basic parameters of the gear are: modulus m n =1.25, number of teeth z=43, gear helix angle β=24°, pressure angle α=20°. The basic parameters of the hob are: modulus m n =1.25, number of heads z=1, hob helix angle β=2.33°, pressure angle α=20°. The feeding method is axial and radial continuous feeding. Use the JD45 gear measuring center to detect the tooth profile errors.

[0075] 2. Process parameters

[0076] The ranges of the four hobbing process factors are:

[0077] Hob speed 800S d z <15.

[0078] 3. The operation steps for improving the hobbing precision are the same as in Embodiment 1.

[0079] 4. Results.

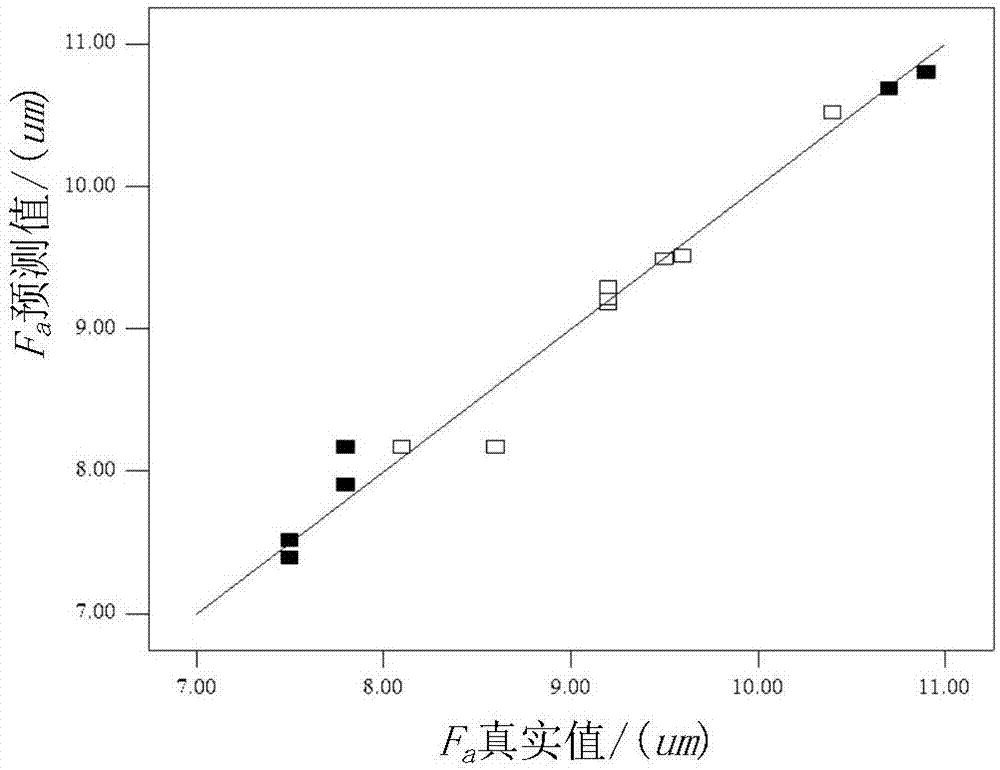

[0080] The optimal combination of gear hobbing process parameters obtained by this method is: hob speed S S =1420(r / min); hobbing depth h d =0.75(mm); A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com