Rime-like metal-organic framework composite microelectrode and its in-situ preparation method and application

A metal-organic framework and organic framework technology, applied in the field of nanomaterials, can solve problems such as energy consumption, environmental pollution, complex and multi-step synthesis methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

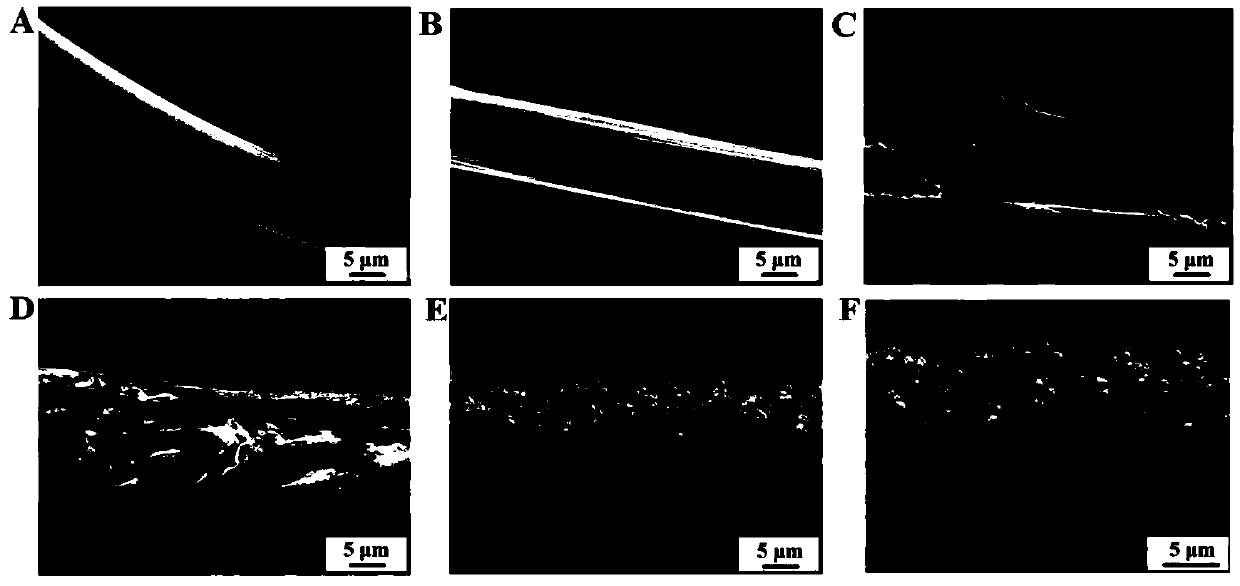

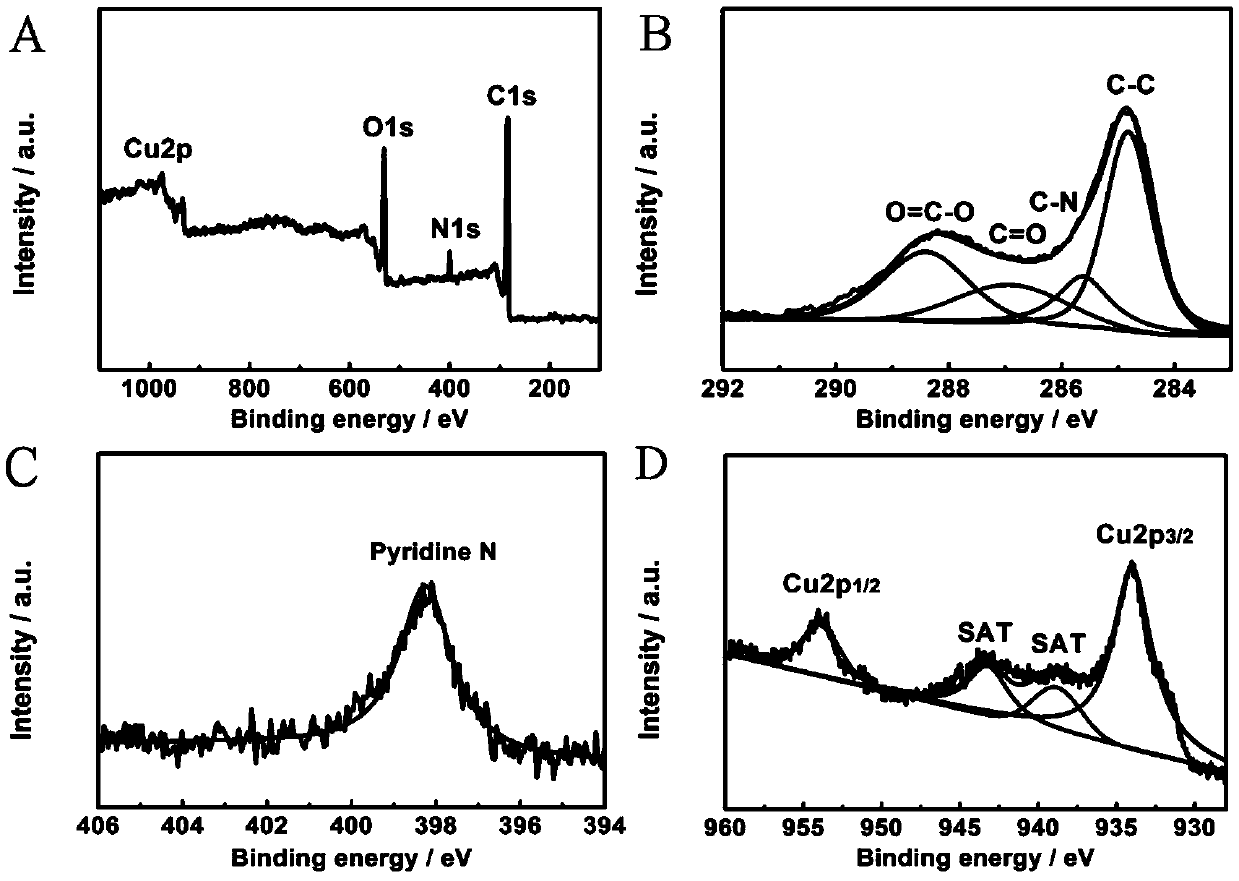

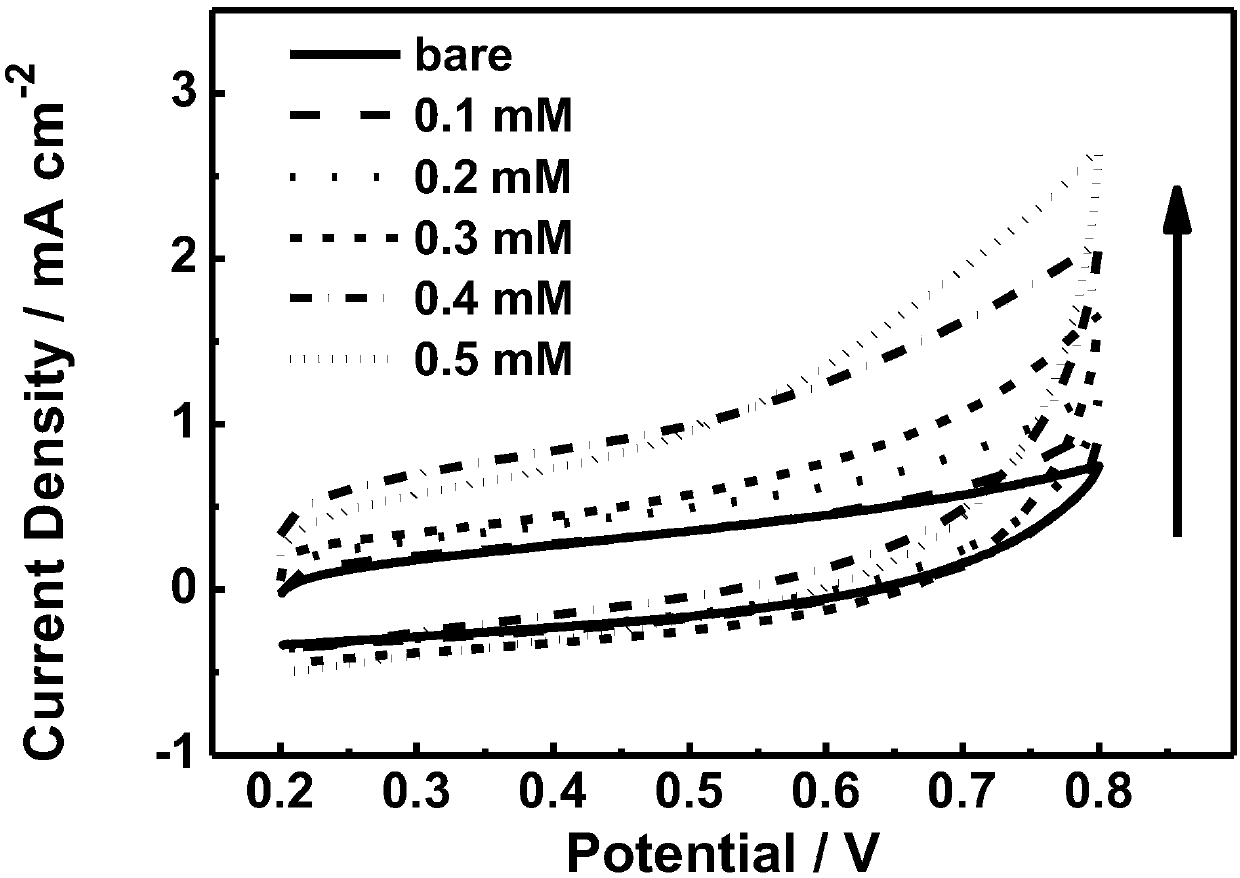

[0040] A rime-like copper organic framework [Cu(INA) 2 ] / Three-dimensional graphene-coated carbon fiber composite microelectrodes, including three-dimensional graphene-coated activated carbon fibers and rime-like copper organic frameworks on the graphene surface [Cu(INA) 2 ], the surface of the three-dimensional graphene-coated activated carbon fibers is porous. The rime-like copper organic framework [Cu(INA) 2 ] uniformly deposited on the surface layer of the three-dimensional graphene-coated activated carbon fiber. The diameter of the three-dimensional graphene-coated activated carbon fiber is about 15 μm, and the surface is a loose porous network structure formed by stacking graphene nanosheets; the rime-like copper organic framework [Cu(INA) 2 ] The material is evenly distributed on the three-dimensional network structure formed by stacking graphene nanosheets, with uniform holes and a diameter of about 1 μm. Such as figure 1 E and figure 1 As shown in F, its microst...

Embodiment 2

[0048] A rime-like copper organic framework [Cu(INA) 2 ] / Three-dimensional graphene-coated carbon fiber composite microelectrodes, including three-dimensional graphene-coated activated carbon fibers and rime-like copper organic frameworks on the graphene surface [Cu(INA) 2 ], the surface of the three-dimensional graphene-coated activated carbon fibers is porous. The rime-like copper organic framework [Cu(INA) 2 ] uniformly deposited on the surface layer of the three-dimensional graphene-coated activated carbon fiber. The diameter of the three-dimensional graphene-coated activated carbon fiber is about 13 μm, and the surface is a loose porous network structure formed by stacking graphene nanosheets; the rime-like copper organic framework [Cu(INA) 2 ] The material is evenly distributed on the three-dimensional network structure formed by stacking graphene nanosheets, with uniform holes and a diameter of about 1.1 μm.

[0049] A kind of rime-like copper organic framework [Cu(...

Embodiment 3

[0055] A rime-like copper organic framework [Cu(INA) 2 ] / Three-dimensional graphene-coated carbon fiber composite microelectrodes, including three-dimensional graphene-coated activated carbon fibers and rime-like copper organic frameworks on the graphene surface [Cu(INA) 2 ], the surface of the three-dimensional graphene-coated activated carbon fibers is porous. The rime-like copper organic framework [Cu(INA) 2 ] uniformly deposited on the surface layer of the three-dimensional graphene-coated activated carbon fiber. The diameter of the three-dimensional graphene-coated activated carbon fiber is about 10 μm, and the surface is a loose porous network structure formed by stacking graphene nanosheets; the rime-like copper organic framework [Cu(INA) 2 ] The material is evenly distributed on the three-dimensional network structure formed by stacking graphene nanosheets, with uniform holes and a diameter of about 1.2 μm.

[0056] A kind of rime-like copper organic framework [Cu(...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com