Building thermal-insulation formwork automatic continuous coating machine and coating method thereof

A kind of coating machine and automatic technology, which is applied in the direction of construction, building structure, and on-site preparation of building components, can solve the problems of inability to guarantee the quality of coating, a large amount of manpower and material resources, and low work efficiency, and achieve good use value , Stable production beat and good coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

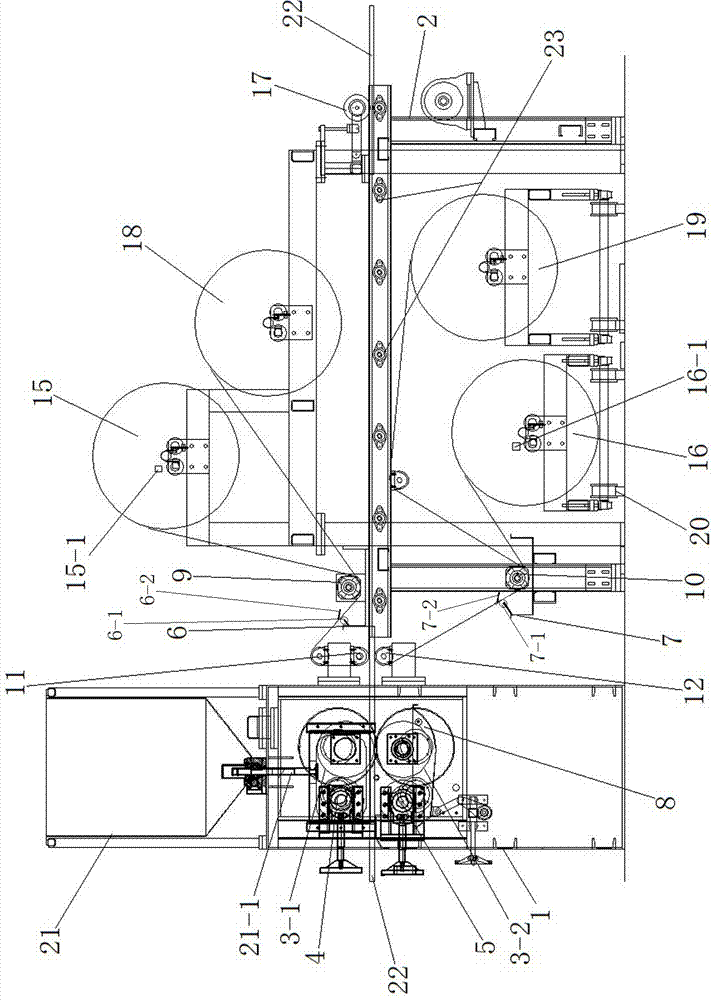

[0028] Refer to attached Figure 1-3 , a hot-pressed embryonic plate automatic coating machine comprises a frame one 1, a frame two 2, a rubber roller, an upper steel roller 4, a lower steel roller 5, a main feeding trough 21, a feeding chute 6, and a feeding chute two 7. Distributing tank three 8, dipping roller one 9, dipping roller two 10, upper tension guide wheel 11, lower tension guide wheel 12, transmission motor 13, transmission box 14, upper coil 15, lower coil 16 and control device.

[0029] Rubber roller, upper steel roller 4, lower steel roller 5, main hopper 21, distribution chute 3 8, upper tension guide wheel 11, lower tension guide wheel 12, transmission motor 13 and Transmission box 14; On the frame two 2, a material distribution tank 6, a material distribution tank 2 7, a dipping roll 9, a dipping roll 2 10, an upper coil 15 and a lower coil 16 are installed;

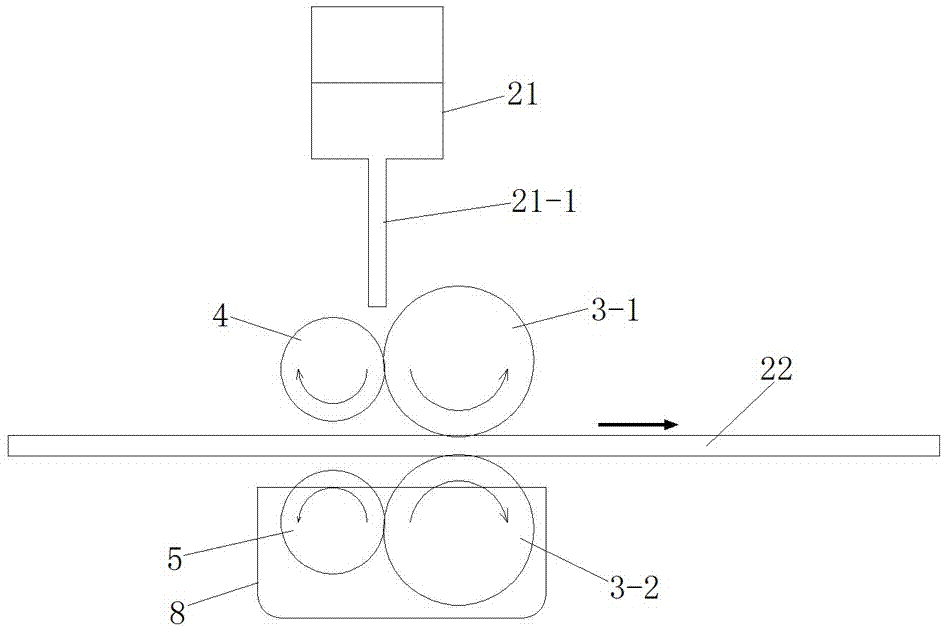

[0030] Described rubber roller comprises upper rubber roller 3-1 and lower rubber roller 3-2, bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com