Composting reactor system capable of achieving intelligent layered aeration

A composting reactor and aeration system technology, applied in the field of intelligent composting reactor systems, can solve the problems of serious odor release, low processing efficiency, high energy consumption, etc., to reduce odor emissions, realize recycling, and prolong use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below, various embodiments of the intelligent layered aeration composting reactor system according to the present invention will be described in detail with reference to the accompanying drawings.

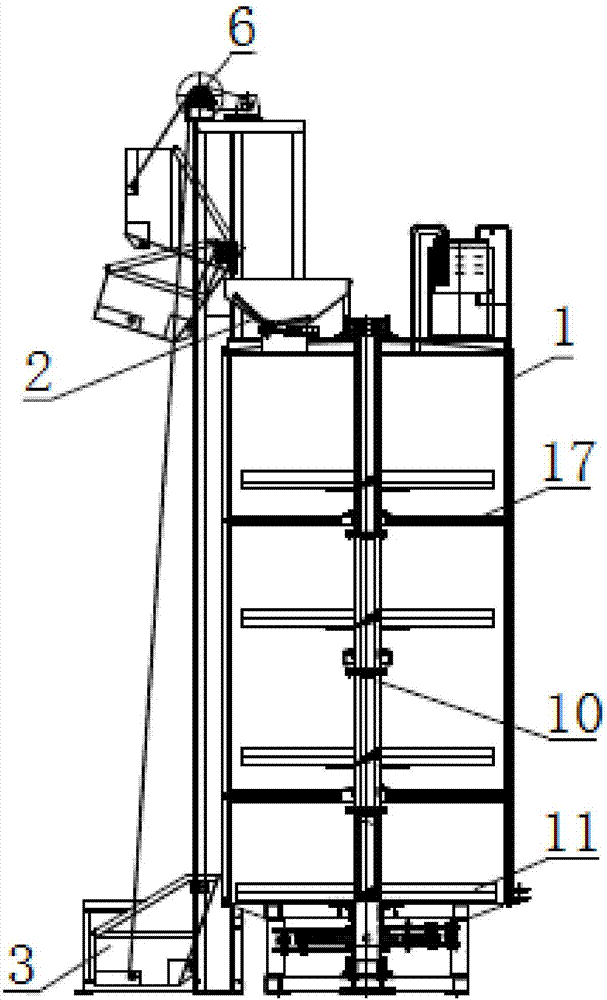

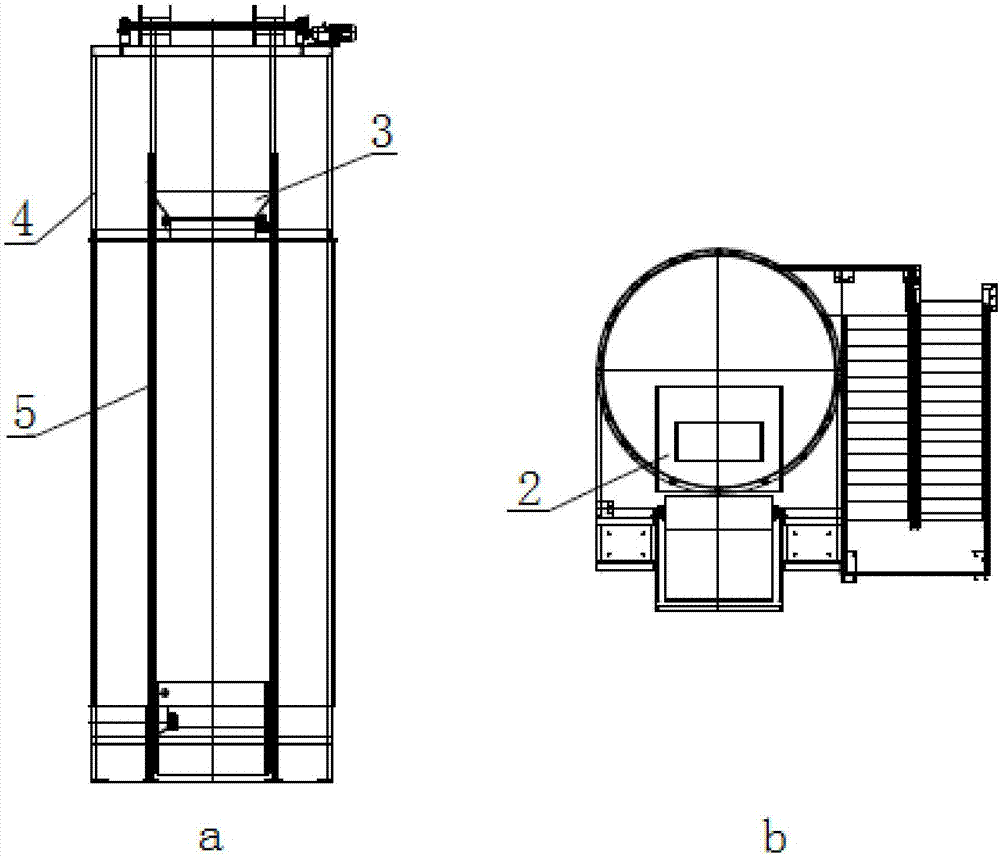

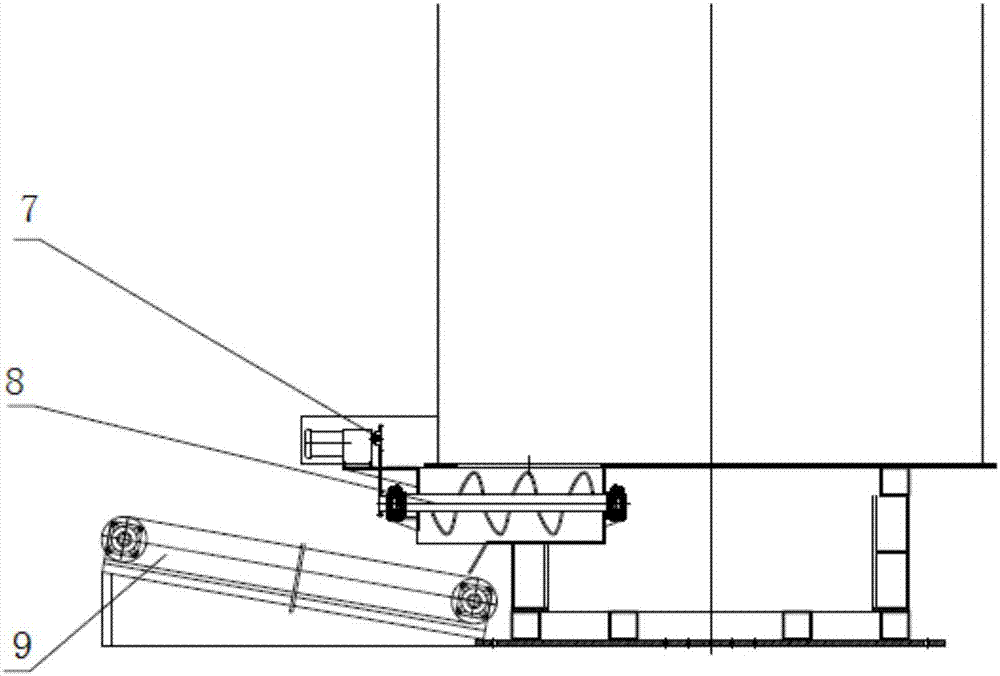

[0031] figure 1 A schematic diagram of a preferred embodiment of the intelligent layered aeration composting reactor system according to the present invention is shown. For example, the intelligent layered aeration composting reactor system according to the present invention includes a composting reactor, a feeding system, a discharging system, a stirring system, an aeration system, a tail gas recovery treatment system and a control unit. The control unit is, for example, a programmable logic controller (PLC), is connected to each of the above-mentioned systems, and controls their operations. Specifically, the composting reactor includes a tank body 1 , a feed inlet 2 arranged at the top of the tank body 1 , and a discharge port (not shown) arranged at the bottom of the tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com