A double-layer structure oxidation ditch

A double-layer structure, oxidation ditch technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problem of reducing the effective volume of the oxidation ditch, reducing the water treatment effect and reducing the ditch bottom flow rate and other issues, to improve the effect of sewage treatment, ensure that heat is not lost, and increase the separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, which are explanations rather than limitations of the present invention.

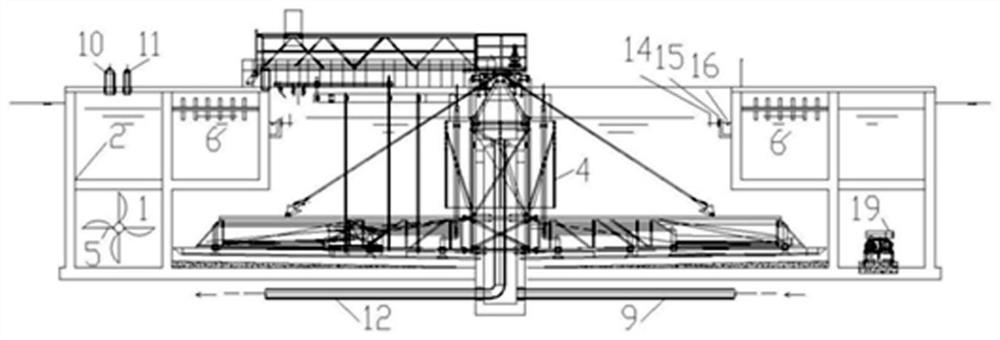

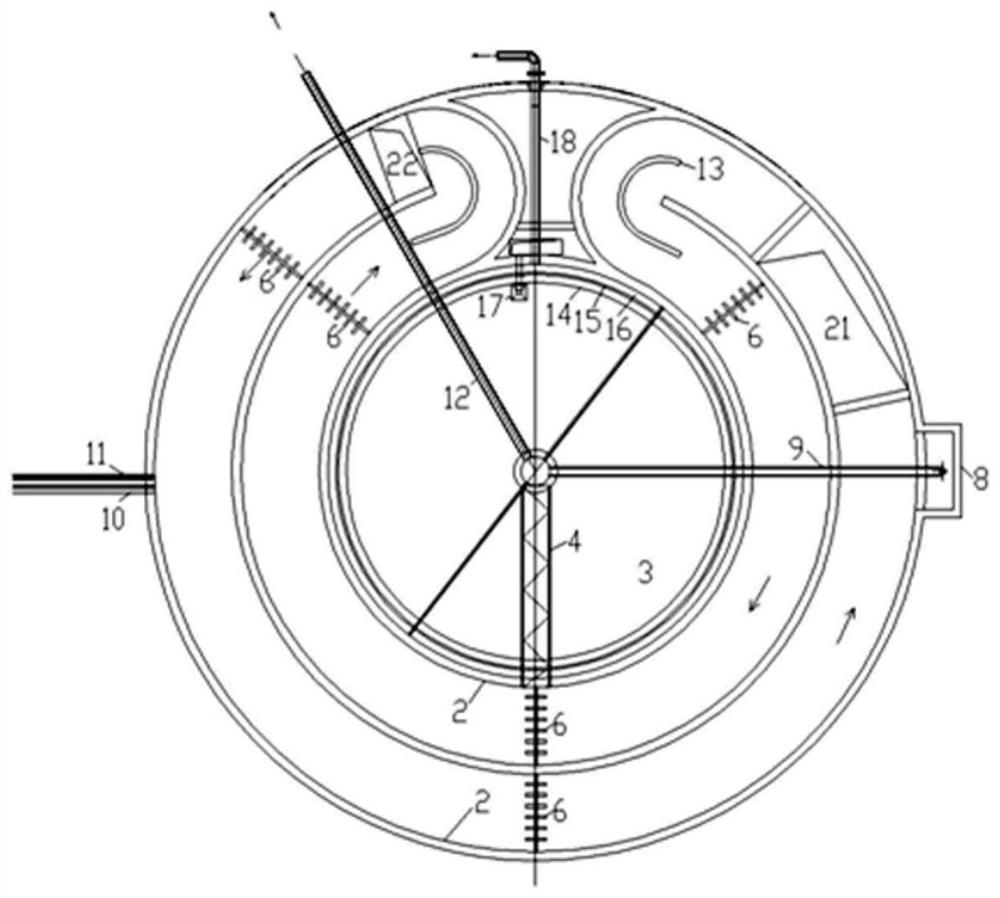

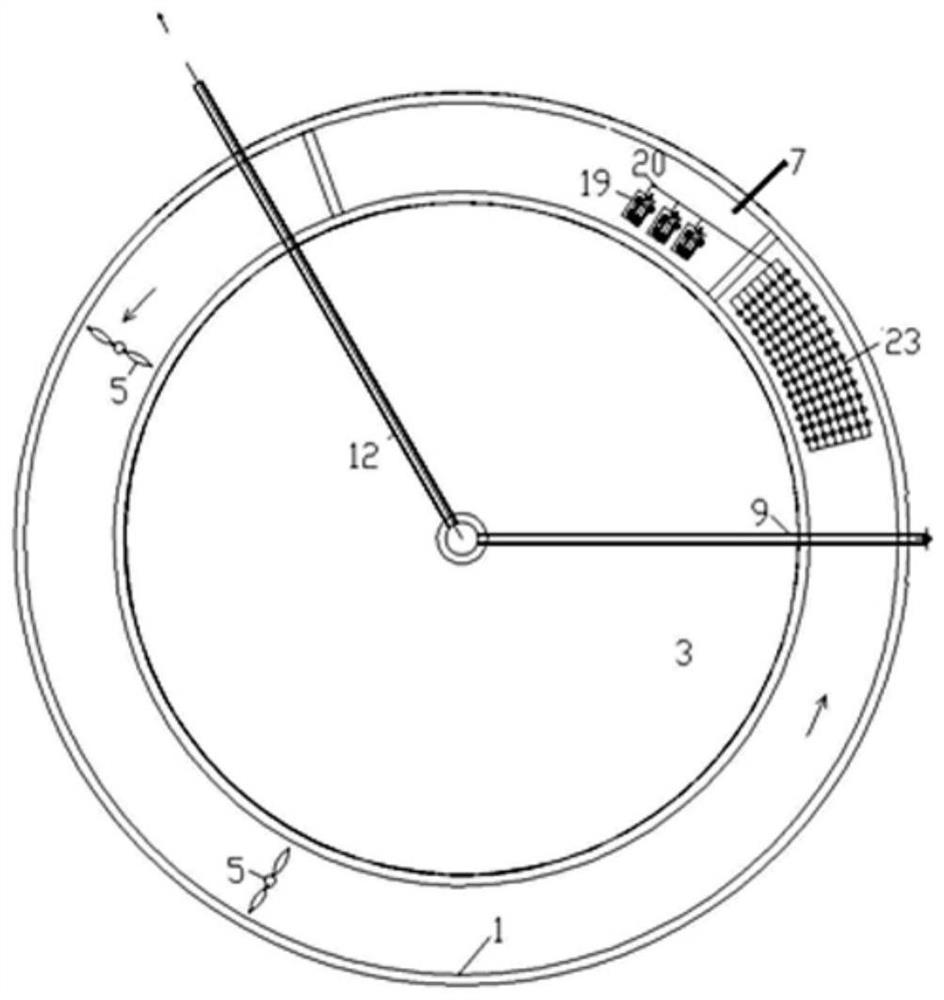

[0042] The invention provides a novel double-layer structure oxidation ditch, the structure of which is as follows: Figure 1~3 Shown, comprise pond body, and pond body is made up of anoxic pond 1, aerobic pond 2 and secondary settling pond 3; And pond body is provided with oxidation ditch water inlet pipe 10 and return sludge water inlet pipe 11; The return sludge inlet pipes 11 are all connected to the anoxic tank 1 . The aerobic pool 2 and the anoxic pool 1 form an upper and lower double-layer structure in the pool body, wherein the aerobic pool 2 is located on the upper layer of the upper and lower double-layer structure, and the anoxic pool 1 is located on the lower layer of the double-layer structure.

[0043] The aerobic pool 2 is a ring-shaped baffle str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com