A flue gas desulphurization and regeneration method for an ordered graded porous carbon material

A technology for grading porous carbon and flue gas, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as difficult practical application, inability to provide migration power, and reduction of activated carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Melt 40g of phenol at 45°C, add 8.5g of 20% NaOH aqueous solution drop by mass, stir for 10min, then add formaldehyde solution with a mass concentration of 37% dropwise, wherein the molar ratio of phenol / formaldehyde It is 1:3. The mixed solution was reacted at 85° C. for 1 h, then cooled to room temperature, and the pH value of the mixed solution was adjusted to 7.0 with 20% HCl aqueous solution. The mixed solution was dried in a rotary evaporator to obtain a phenolic resin oligomer, which was prepared by adding absolute ethanol to prepare a phenolic resin solution with a mass fraction of 15% for use.

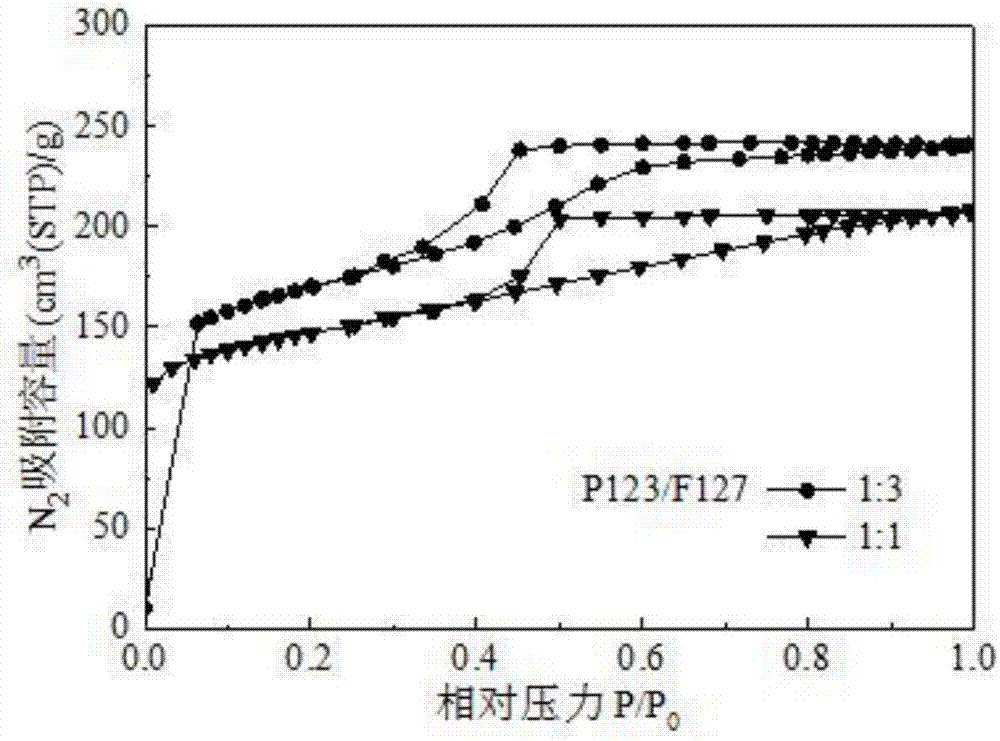

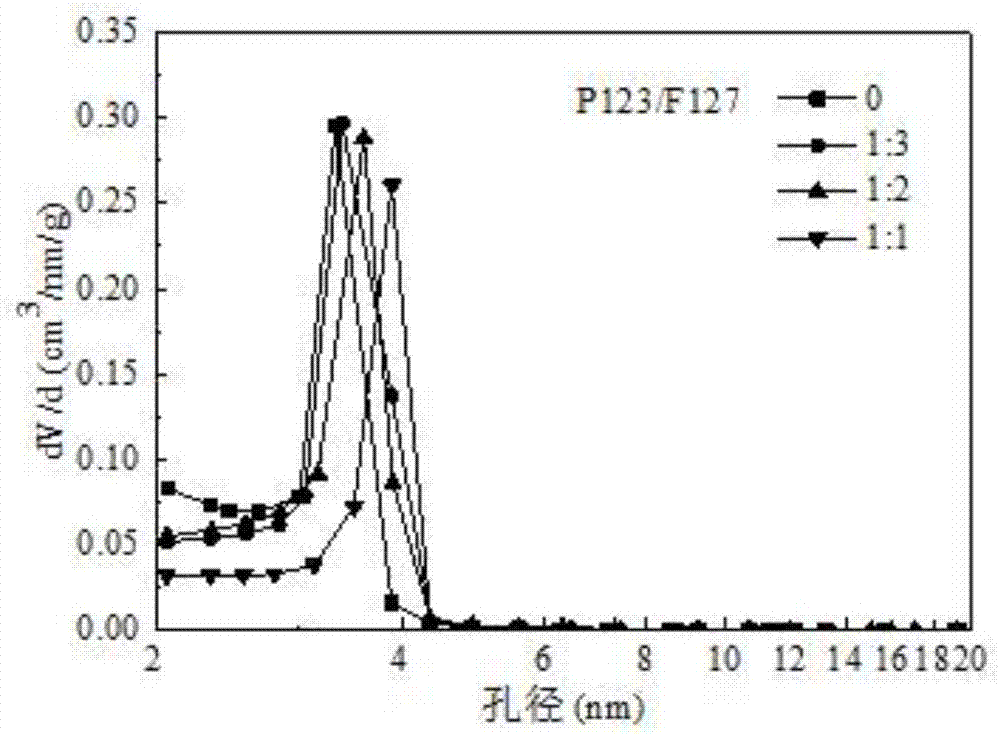

[0039] Take the mixture of triblock copolymer F127 and P123 as the template agent, wherein the mass ratio of P123 / F127 is 1:3, mix the phenolic resin solution with the ethanol solution of the template agent with a mass percentage of 10%, and stir until a uniform solution is obtained, The mass ratio of the phenolic resin to the template agent is 1:1. The obtained s...

Embodiment 2

[0043] (1) Melt 40g of phenol at 45°C, add 8.5g of 20% NaOH aqueous solution dropwise, stir for 10min, then add dropwise a 37% formaldehyde aqueous solution, wherein the molar ratio of phenol / formaldehyde It is 1.2:3. The mixed solution was reacted at 85° C. for 2 h, then cooled to room temperature, and the pH value of the mixed solution was adjusted to 7.0 with 20% by mass percent HCl aqueous solution. The mixed solution was dried in a rotary evaporator to obtain a phenolic resin oligomer, which was prepared by adding absolute ethanol to prepare a phenolic resin solution with a mass fraction of 15% for use.

[0044] Take the mixture of triblock copolymer F127 and P123 as the template agent, wherein the mass ratio of P123 / F127 is 1:2, mix the phenolic resin solution with the ethanol solution of the template agent with a mass percentage of 10%, and stir until a uniform solution is obtained, The mass ratio of the phenolic resin to the template agent is 1:1. The obtained soluti...

Embodiment 3

[0048] (1) 45g phenol is melted at 50 ℃, dropwise adding 10g mass concentration is 20% NaOH aqueous solution, stirs 10min, then dropwise adding dropwise is 37% formaldehyde aqueous solution, wherein the mol ratio of phenol / formaldehyde is 1:3. The mixed solution was reacted at 90°C for 1 h, then cooled to room temperature, and the pH value of the mixed solution was adjusted to 7.0 with 20% HCl aqueous solution. The mixed solution was dried in a rotary evaporator to obtain a phenolic resin oligomer, which was prepared by adding absolute ethanol to prepare a 20% by mass phenolic resin solution for use.

[0049]Take the mixture of triblock copolymer F127 and P123 as the template agent, wherein the mass ratio of P123 / F127 is 1:1, mix the phenolic resin solution with the ethanol solution of the template agent with a mass percentage of 10%, and stir until a uniform solution is obtained, The mass ratio of the phenolic resin to the template agent is 1:1. The obtained solution was tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com