Automatic paving method and device of fiber cloth for wind power blade main beam molding

A technology of wind power blades and fiber cloth, which is applied in the field of automatic laying of fiber cloth for forming the main beam of wind power blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

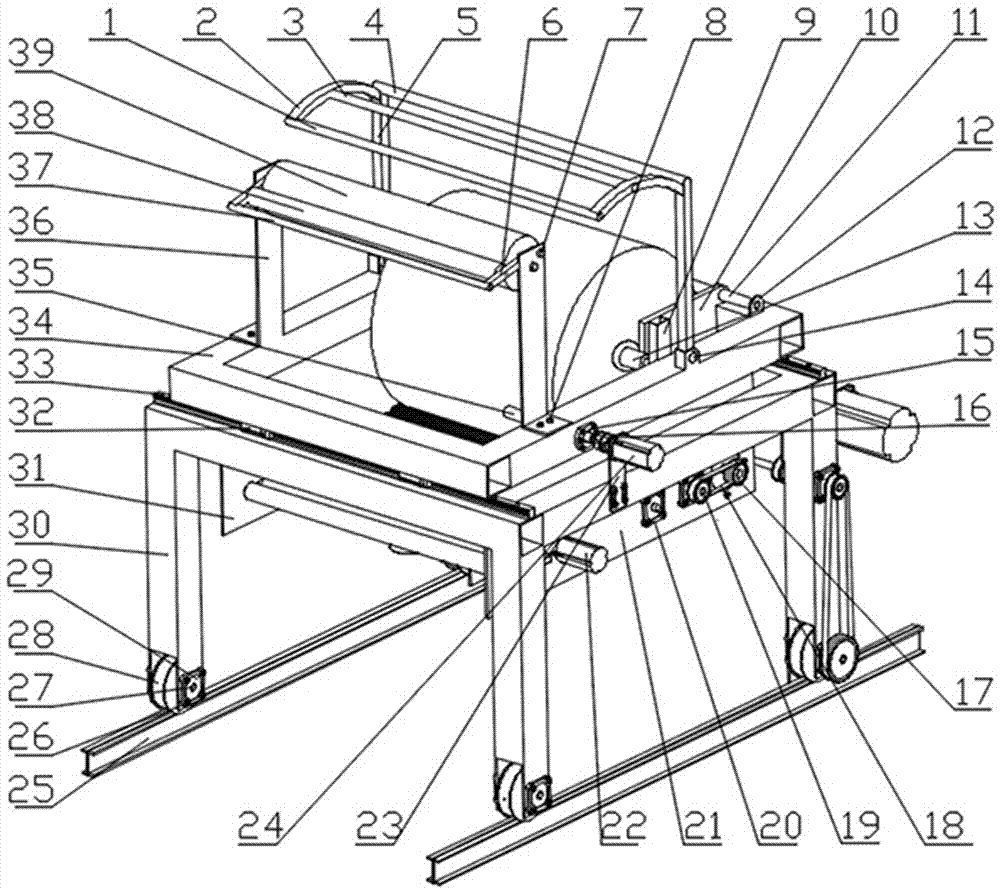

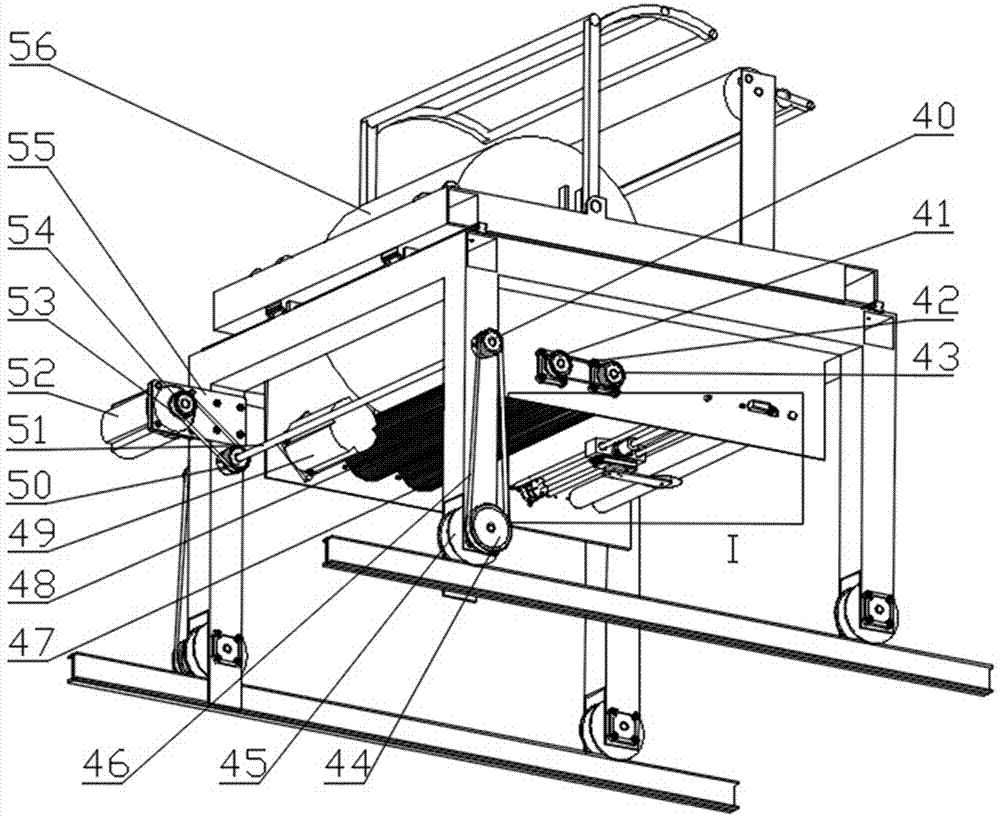

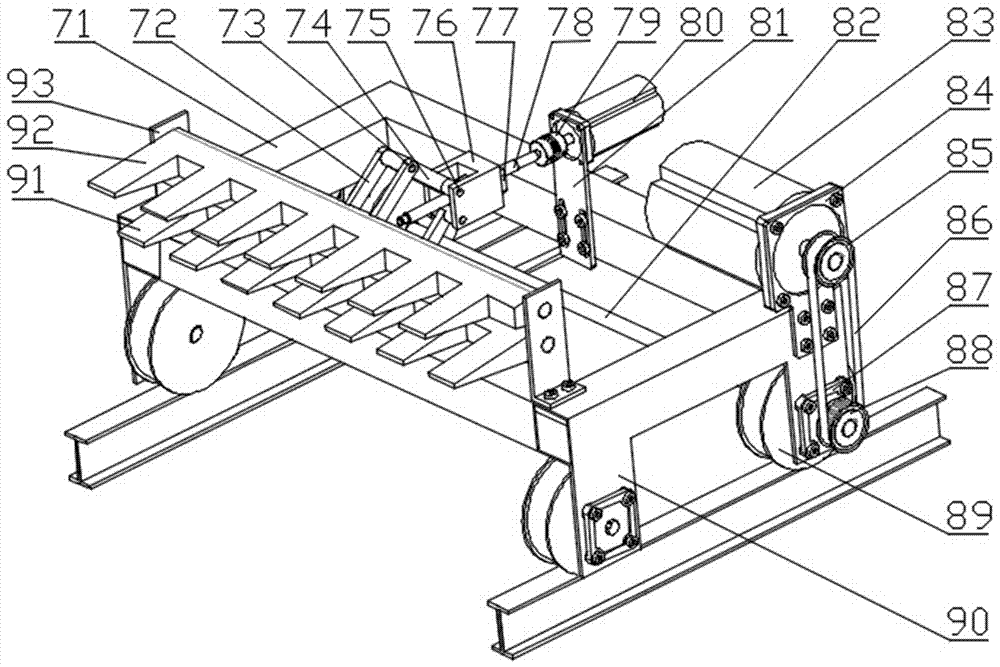

[0011] 1. Fabric frame beam Ⅰ 2. Fabric frame connecting frame Ⅱ 3. Fabric frame beam Ⅱ 4. Fabric frame beam Ⅲ 5. Fabric frame connecting frame Ⅰ 6. Rubber roller connecting frame 7. Pin Ⅰ 8, screw Ⅰ 9, chute 10. Baffle plate 11, baffle plate fixed shaft 12, fixed support 13, cloth roll fixed mandrel 14, pin II 15, screw nut I 16, coupling I 17, synchronous pulley II 18, synchronous belt I 19 , synchronous pulley Ⅰ 20, bearing seat Ⅰ 21, lower support plate Ⅱ 22, cloth cutting motor 23, adjustment motor support plate 24, adjustment motor 25, guide rail 26, screw Ⅱ 27, travel shaft 28, travel wheel Ⅱ 29, bearing Seat II 30, lower frame 31, lower support plate I 32, slider 33, guide rail 34, upper frame 35, lead screw 36, rubber roller support plate 37, operating beam 38, small rubber roller 39, large rubber roller 40, Timing pulley Ⅶ 41, timing pulley Ⅲ 42, timing belt Ⅱ 43, timing pulley Ⅳ 44, timing pulley Ⅷ 45, walking wheel Ⅰ 46, timing belt Ⅳ 47, cloth feeding rubber wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com