Industrial automatic feeding device applied to cylinder materials

An industrial automation and cylinder technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of failure to realize continuous and effective separation and automatic supply of bars, and the effect is not ideal, to achieve fast and effective separation, structure Simplicity and the effect of reducing the involvement of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with specific embodiments.

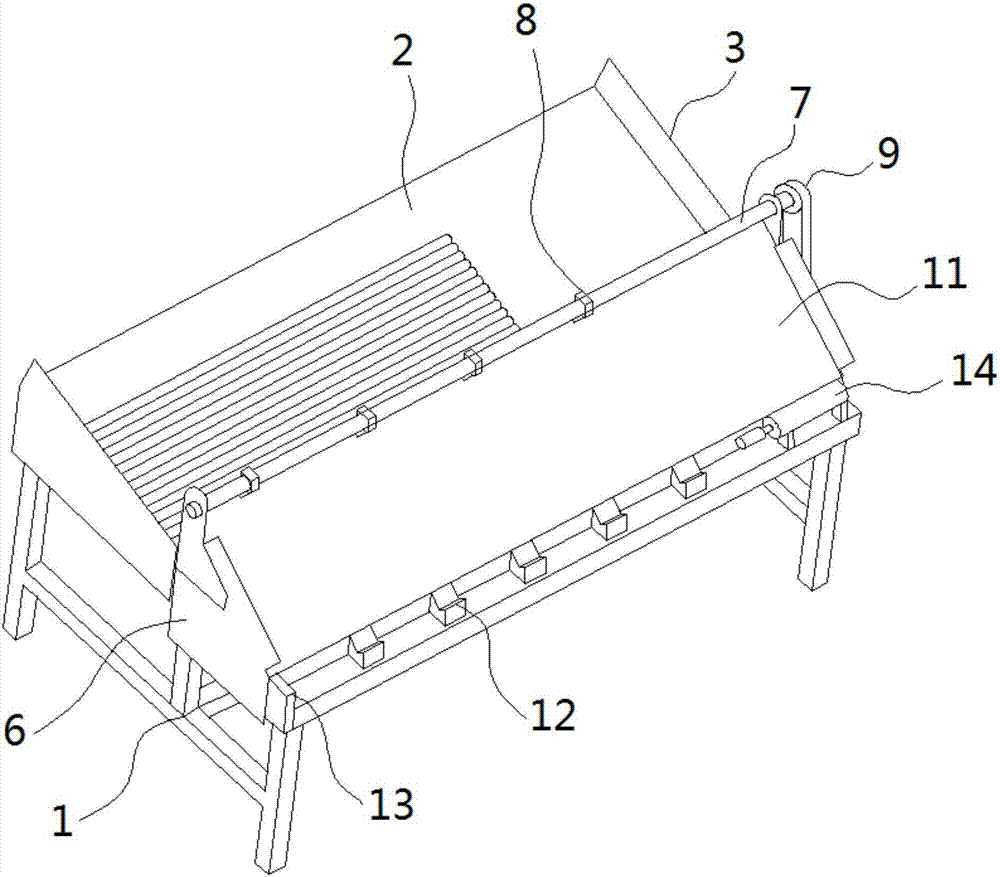

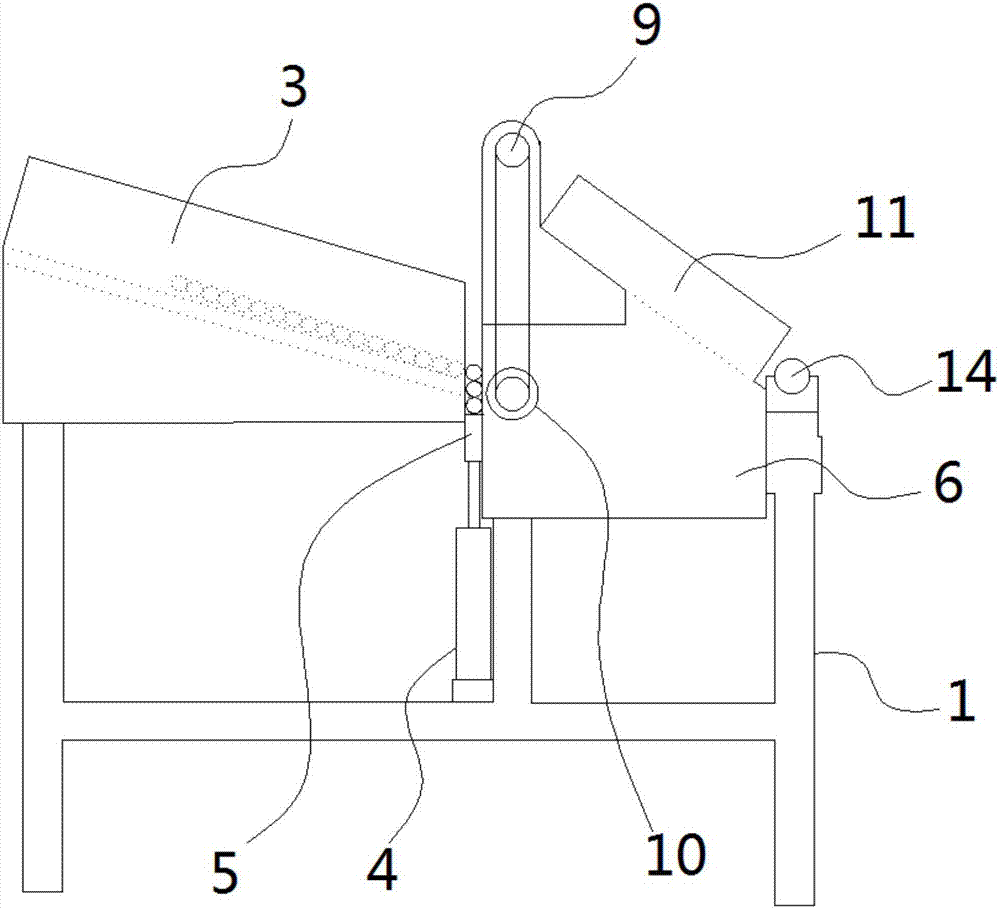

[0015] Such as Figure 1-2 As shown, an industrial automatic feeding device applied to cylindrical materials includes a wool bin, a material distribution mechanism and a positioning mechanism; Leave gaps between agencies.

[0016] The wool bin is composed of a plane sheet metal 2 arranged at a slant and a baffle plate 3 arranged at the left and right ends of the plane sheet metal 2; when the device is in operation, cylindrical materials are added to the wool bin from the upper end of the plane sheet metal 2, and the cylindrical When bulking materials, place the materials close to a baffle plate 3.

[0017] The material distribution mechanism includes a first cylinder 4 fixed on the bracket, and the telescopic end of the first cylinder 4 is connected with a wedge-shaped push plate 5; specifically, a beam is connected to the middle of the bracket 1, and the first cylinder 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com