TPU light conveyor belt and preparation method thereof

A lightweight conveyor belt technology, applied in conveyors, chemical instruments and methods, transportation and packaging, etc., can solve the problems of contaminated food, large equipment investment, toxicity, etc., achieve simple production process, improve elasticity and heat dissipation capacity, tight connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

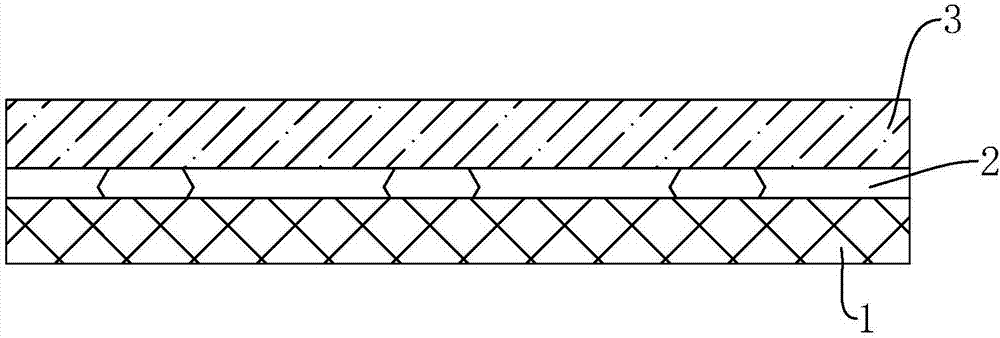

[0035] Such as figure 1 Shown, a kind of TPU light conveyor belt and preparation method thereof, comprise conveying base cloth 1. A TPU hot-melt adhesive film 2 is arranged on the conveying base cloth 1 , and a TPU layer 3 is arranged on the TPU hot-melt adhesive film 2 . The conveying base cloth 1, the TPU hot-melt adhesive film 2, and the TPU layer 3 are bonded together by high-temperature hot pressing. Through the above setting, compared with using glue to bond the conveying base cloth 1 and the TPU layer 3 . This bonding method can reduce the pollution caused by the volatilization of glue, and does not need to produce glue specially, which reduces the process. Since the TPU layer 3 and the TPU hot-melt adhesive film 2 belong to the same material, their bonding effect is better when bonding.

[0036] Optimally, the temperature of the high-temperature hot pressing is 120-130°C. At this temperature, compared with 160-180°C in the prior art, on the one hand, the purpose of...

Embodiment 2

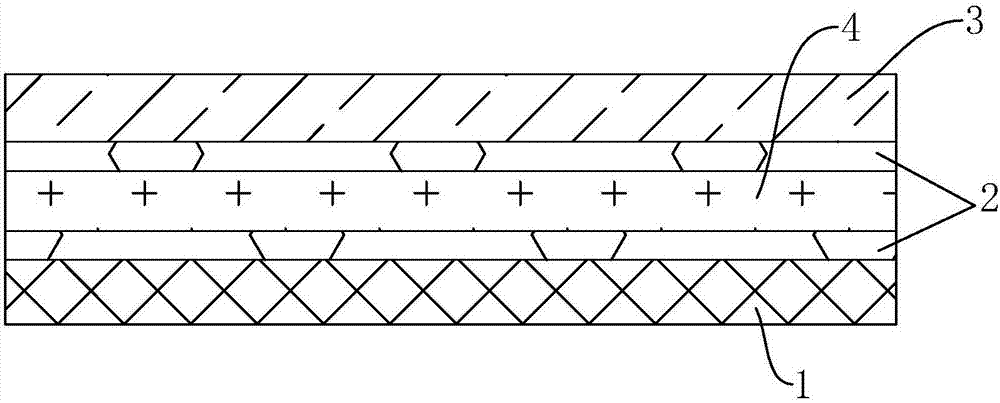

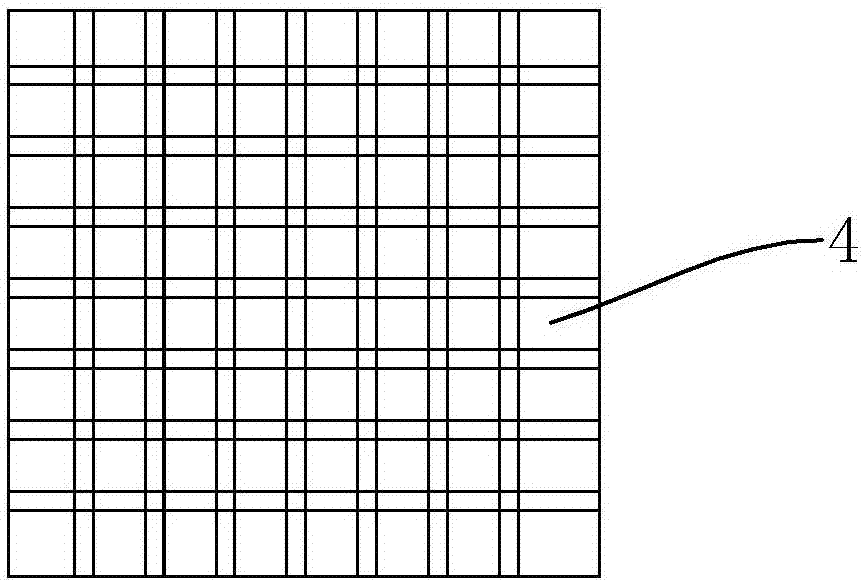

[0043] like figure 2 and image 3 As shown, the difference from Example 1 is that a polypropylene layer 4 is also arranged between the TPU layer 3 and the TPU hot-melt adhesive film 2, and the same TPU hot-melt adhesive film is arranged between the polypropylene layer 4 and the TPU layer 3 2. Under high-temperature hot pressing, the TPU hot-melt adhesive film 2 on both sides of the polypropylene layer 4 melts, thereby bonding the polypropylene layer 4, the TPU layer 3 and the conveying base cloth 1 to each other. By setting the polypropylene fiber layer 4, the TPU light-duty conveyor belt has better elasticity, preventing the TPU light-duty conveyor belt from being deformed and broken due to excessive tension during the tensioning process.

[0044] Optimally, the polypropylene layer 4 is a mesh structure. By setting the polypropylene fiber layer 4 into a mesh structure, the heat dissipation capacity of the TPU light conveyor belt is improved, so that the TPU light conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com