Flatness inspection machine

A technology of inspection machine and flatness, which is applied in the field of inspection instruments, can solve the problems of poor accuracy of monitoring data, large deviation of discretionary tolerance, and slow detection speed, etc., and achieve the effect of improving accuracy, reducing measurement tolerance, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

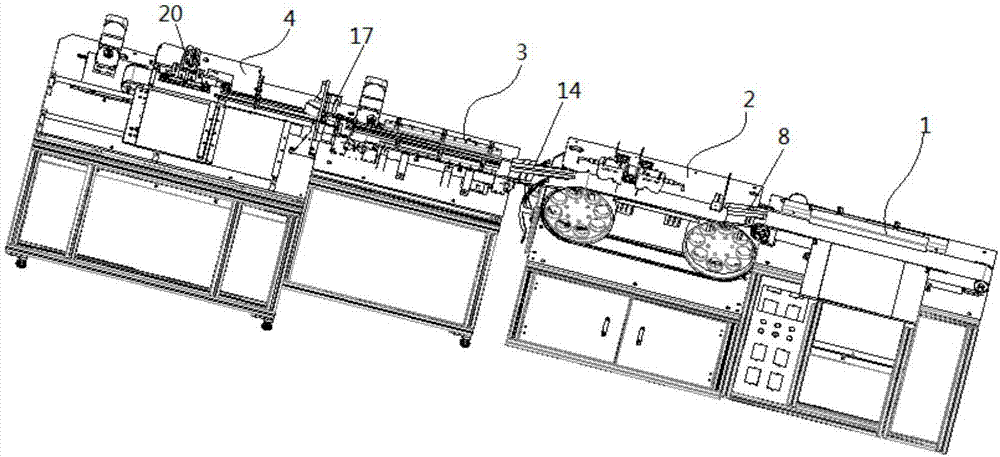

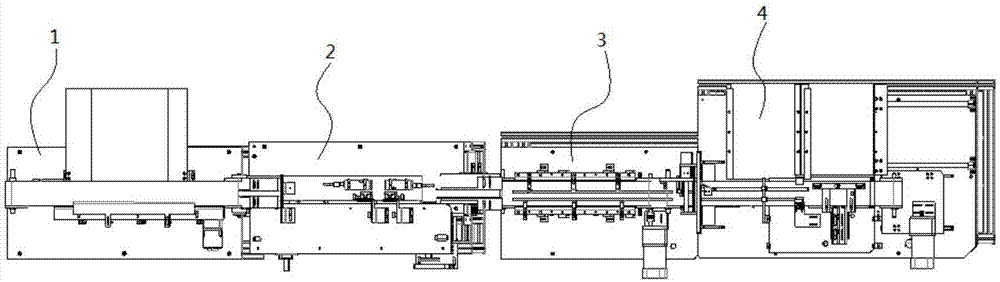

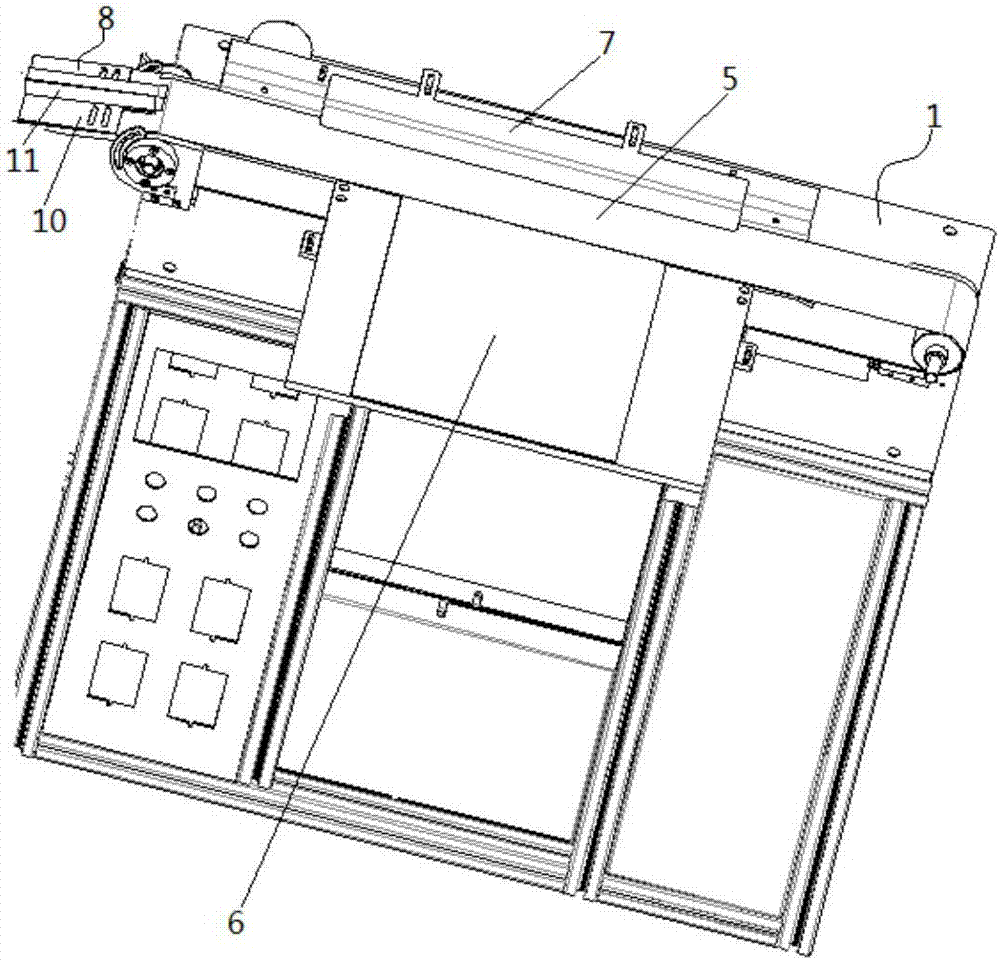

[0033] like Figure 1-6As shown, a flatness inspection machine is disclosed in this embodiment, which includes a feeding transmission mechanism 1, a scanning detection mechanism 2, a sorting and picking mechanism 173 and a circular discharge mechanism 4, and is characterized in that: There is a feeding conveyor belt 5, one side of the feeding conveyor belt 5 is provided with a feeding plate 6, and the other side of the feeding conveyor belt 5 is provided with a limit mechanism 7, and the limit plate on the limit mechanism 7 is parallel to the feeding plate. The transmission direction of the conveyor belt 5 is set; the transmission end of the feeding conveyor belt 5 is provided with a first sorting and shaping mechanism 8, and the other end of the first sorting and shaping mechanism 8 is connected to the scanning detection mechanism 2 to detect the initial transmission of the conveyor belt 9. end connection, the main body of the first sorting and shaping mechanism 8 is a transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com