Preparation method of magnetic adsorptive material and application thereof

A technology of magnetic adsorption materials and dosage, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of high cost and poor effect, achieve good effect, simple preparation process, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

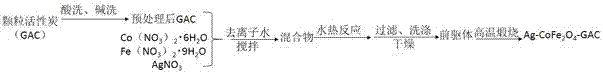

[0022] like figure 1 Shown, a kind of preparation method of magnetic adsorption material comprises the steps:

[0023] In the first step, Ag-CoFe was prepared by hydrothermal synthesis 2 o 4 -Precursor of GAC complex: weigh 0.1450g of Co(NO 3 ) 2 ▪6H 2 O, 0.4052g of Fe (NO 3 ) 2 ▪9H 2 O, 0.1260g of AgNO 3 and 0.12g of granular activated carbon GAC, the granular activated carbon GAC was washed with 1mol / L hydrochloric acid and 1mol / L sodium hydroxide to obtain the pretreated GAC, and then the pretreated GAC and Co(NO 3 ) 2 ▪6H 2 O, Fe (NO 3 ) 2 ▪9H 2 O and AgNO 3 Mix and add 80 mL of deionized water to dissolve, stir, and stir the obtained mixture into a reactor for hydrothermal reaction. The hydrothermal reaction temperature is 215° C., and the hydrothermal reaction time is 19 hours.

[0024] The second step, calcination to prepare Ag-CoFe 2 o 4 -GAC complex: the black product obtained after the hydrothermal reaction is filtered through a filter paper with a f...

Embodiment 2

[0027] like figure 1Shown, a kind of preparation method of magnetic adsorption material comprises the steps:

[0028] In the first step, Ag-CoFe was prepared by hydrothermal synthesis 2 o 4 -Precursor of GAC complex: weigh 0.1450g of Co(NO 3 ) 2 ▪6H 2 O, 0.4052g of Fe (NO 3 ) 2 ▪9H 2 O, 0.1260g of AgNO 3 and 0.12g of granular activated carbon GAC, the granular activated carbon GAC was washed with 1mol / L hydrochloric acid and 1mol / L sodium hydroxide to obtain the pretreated GAC, and then the pretreated GAC and Co(NO 3 ) 2 ▪6H 2 O, Fe (NO 3 ) 2 ▪9H 2 O and AgNO 3 Mix and add 80 mL of deionized water to dissolve, stir, and put the obtained mixture into a reactor for hydrothermal reaction after stirring evenly. The hydrothermal reaction temperature is 200° C., and the hydrothermal reaction time is 18 hours.

[0029] The second step, calcination to prepare Ag-CoFe 2 o 4 -GAC complex: the black product obtained after the hydrothermal reaction is filtered through a f...

Embodiment 3

[0032] like figure 1 Shown, a kind of preparation method of magnetic adsorption material comprises the steps:

[0033] In the first step, Ag-CoFe was prepared by hydrothermal synthesis 2 o 4 -Precursor of GAC complex: weigh 0.1450g of Co(NO 3 ) 2 ▪6H 2 O, 0.4052g of Fe (NO 3 ) 2 ▪9H 2 O, 0.1260g of AgNO 3 and 0.12g of granular activated carbon GAC, the granular activated carbon GAC was washed with 1mol / L hydrochloric acid and 1mol / L sodium hydroxide to obtain the pretreated GAC, and then the pretreated GAC and Co(NO 3 ) 2 ▪6H 2 O, Fe (NO 3 ) 2 ▪9H 2 O and AgNO 3 Mix and add 80 mL of deionized water to dissolve, stir, and put the obtained mixture into a reactor for hydrothermal reaction after stirring evenly. The hydrothermal reaction temperature is 230° C., and the hydrothermal reaction time is 20 h.

[0034] The second step, calcination to prepare Ag-CoFe 2 o 4 -GAC complex: the black product obtained after the hydrothermal reaction is filtered through a filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com