Organic-waste-gas treatment system

A technology for treatment system and organic waste gas, which is applied in gas treatment, dispersed particle filtration, membrane technology, etc., and can solve problems such as shutdown and disassembly, inconvenience, and recovery of lost working ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

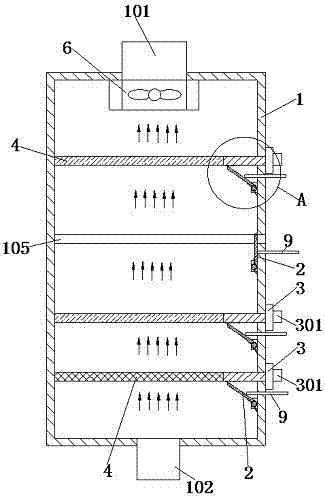

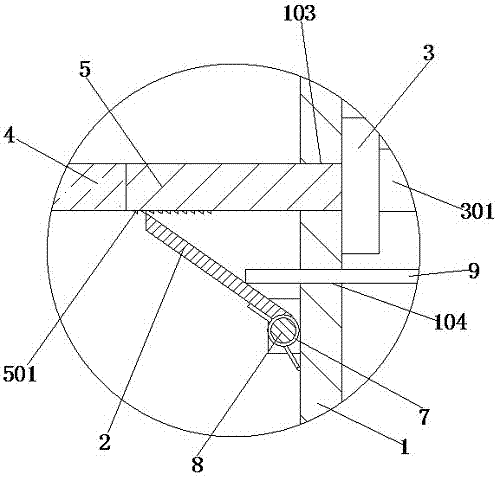

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

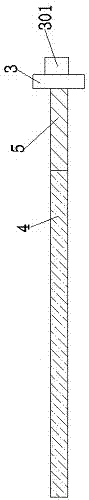

[0018] Such as Figures 1 to 3 As shown, an organic waste gas treatment system according to the present invention includes a box body 1; the top of the box body 1 is provided with an air outlet pipe 101; the bottom of the box body 1 is provided with an air inlet pipe 102; The inner top wall of the box 1 is fixed with a fan 6; the air outlet of the fan 6 communicates with the air outlet pipe 101; the left and right side walls of the box 1 are provided with several guide rail grooves 105; The guide rail groove 105 is arranged symmetrically in the inner cavity of the casing 1; the front surface of the described casing 1 is provided with several opening grooves 103; one end of the guide rail groove 105 is connected with the opening groove 103; One end extends along the horizontal direction; the opening slot 103 is provided with a filtering structure; the filtering structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com